6RRRPRR-based six-degree-of-freedom high-precision adjusting and positioning system

A positioning system, high-precision technology, applied in the field of positioning systems, to achieve the effect of simplifying structural design, low friction, and ensuring structural accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

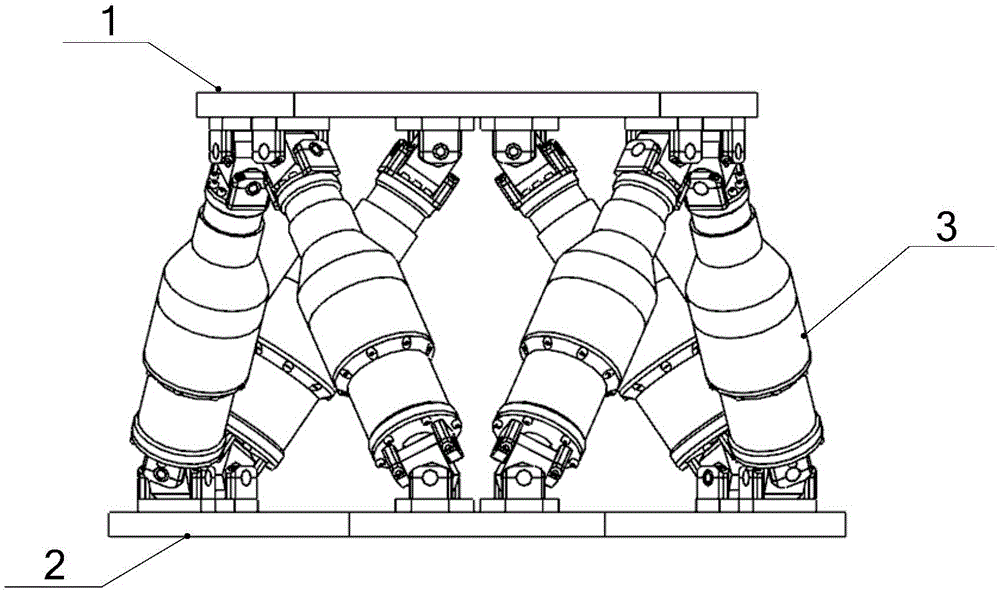

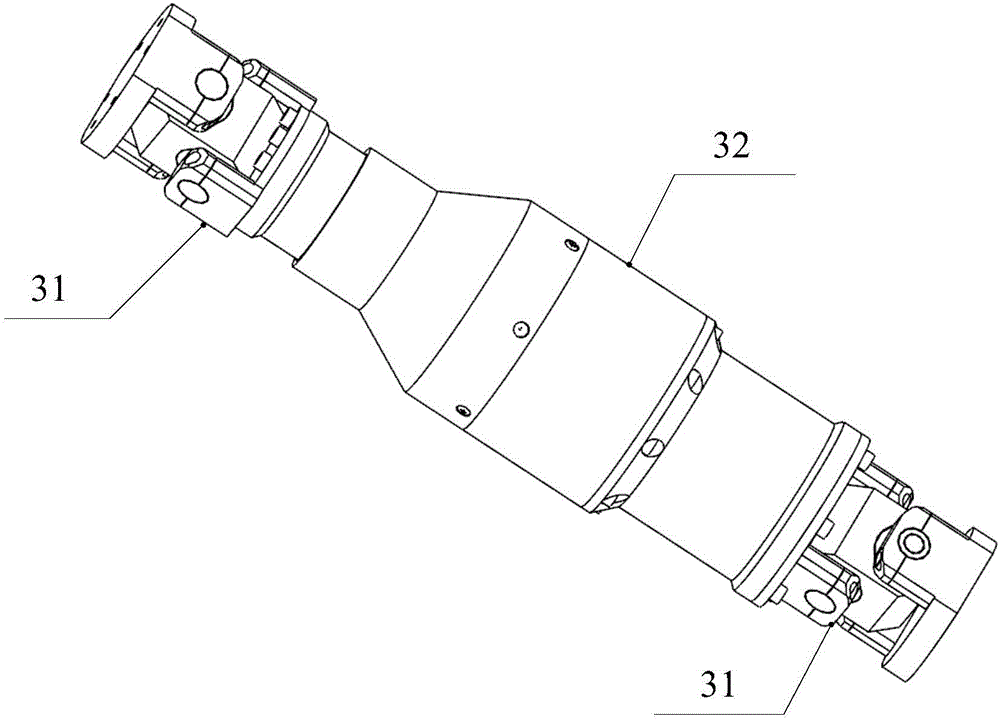

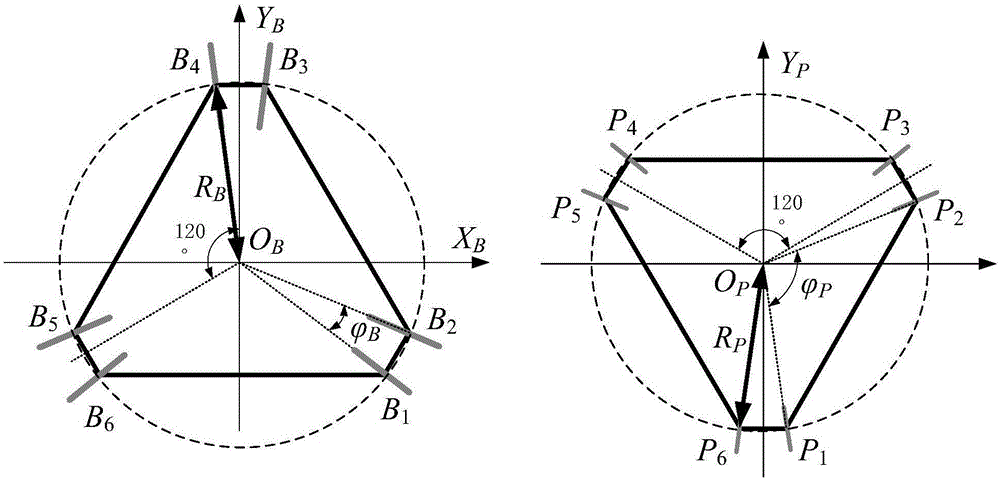

[0034] to combine Figures 1 to 5 To illustrate this embodiment, the six-degree-of-freedom high-precision adjustment and positioning system based on 6RRRPRR of the present invention includes: a moving platform 1, a fixed platform 2 and six support rods 3, and the moving platform 1 and the fixed platform 2 pass through six symmetrical positions from top to bottom. The distributed support rods 3 are connected to each other. The specific installation method is that the moving platform 1, the fixed platform 2 and the support rod 3 are respectively connected by hinges, and the hinge points of the moving platform 1 and the fixed platform 2 are distributed on two different upper and lower circles. P i The connecting lines form a symmetrical hexagon with 6 lower hinge points B i The connecting lines also form a symmetrical hexagon, and the connecting lines between the mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com