Plasma ignition system, control method, and applicable ultra-supercritical boiler

An ultra-supercritical boiler and plasma ignition technology, applied in the field of boiler ignition, can solve problems such as power waste and energy loss in the plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

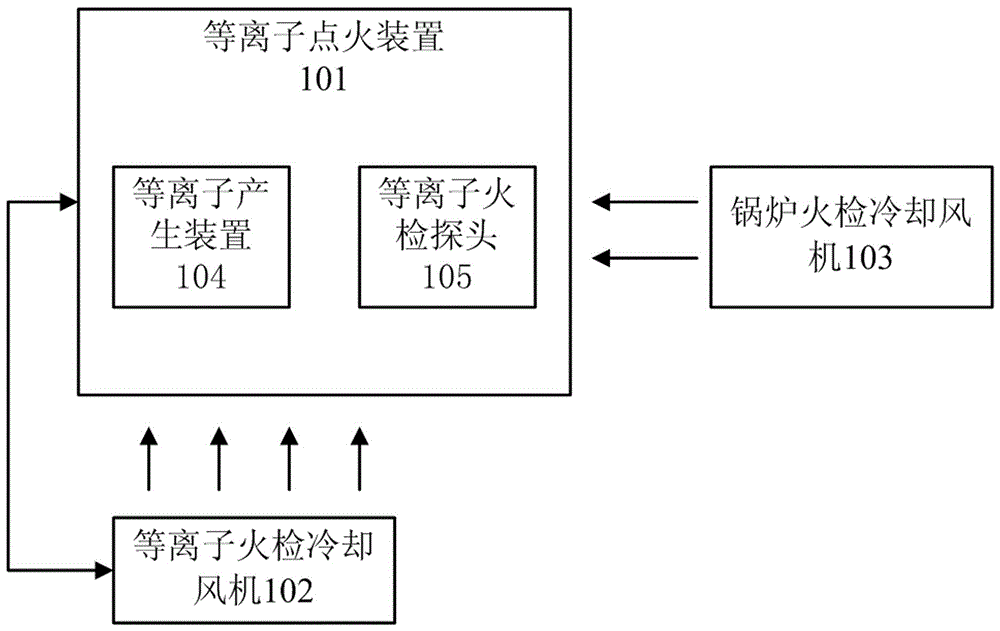

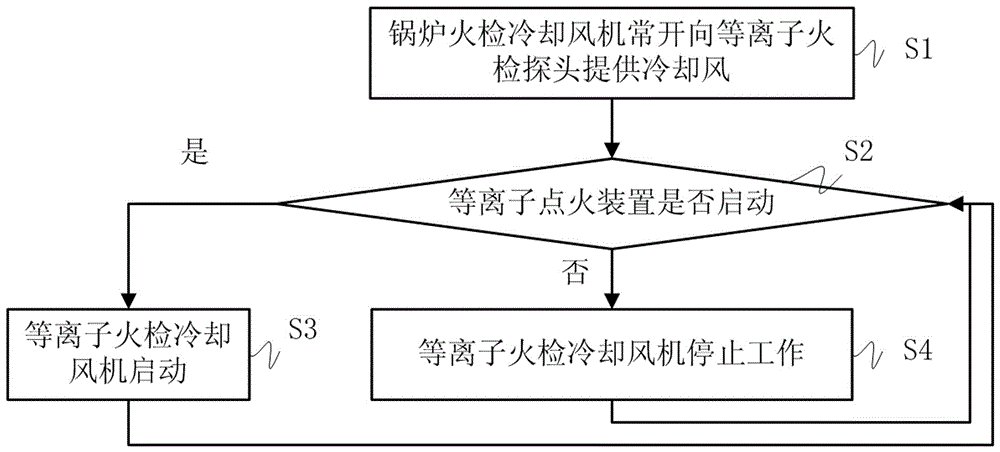

[0026] Such as figure 1 As shown, the present invention discloses a first embodiment of a plasma ignition system. The plasma ignition system includes: a plasma ignition device 101 , a plasma flame detector cooling fan 102 and a boiler flame detector cooling fan 103 .

[0027] The plasma ignition device 101 includes an ignition burner (not shown in the figure), a plasma generating device 105 and a plasma flame detection probe 105 arranged corresponding to the ignition burner.

[0028] The input end of the plasma ignition detection cooling fan 102 is communicatively connected to the plasma ignition device 101 , and the air is directed toward the plasma generation device 102 . When the plasma ignition device 101 is ignited, and the plasma generating device 102 is started, the plasma fire detection cooling fan 102 is triggered to start work, and the plasma carrier wind is provided for the plasma generating device 105;

[0029] The plasma flame detection cooling fan 102 has a flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com