Ultra supercritical boiler with parameter of more than 700 DEG C having secondary re-heating function

An ultra-supercritical boiler and double reheating technology, which is applied to steam boilers, preheating, feed water heaters, etc., can solve the problems of reducing unit efficiency and increasing the superheat of extraction steam, so as to improve unit efficiency, reduce use, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] The object of the present invention is to increase the steam temperature to above 700° C. by adopting the double reheating technology.

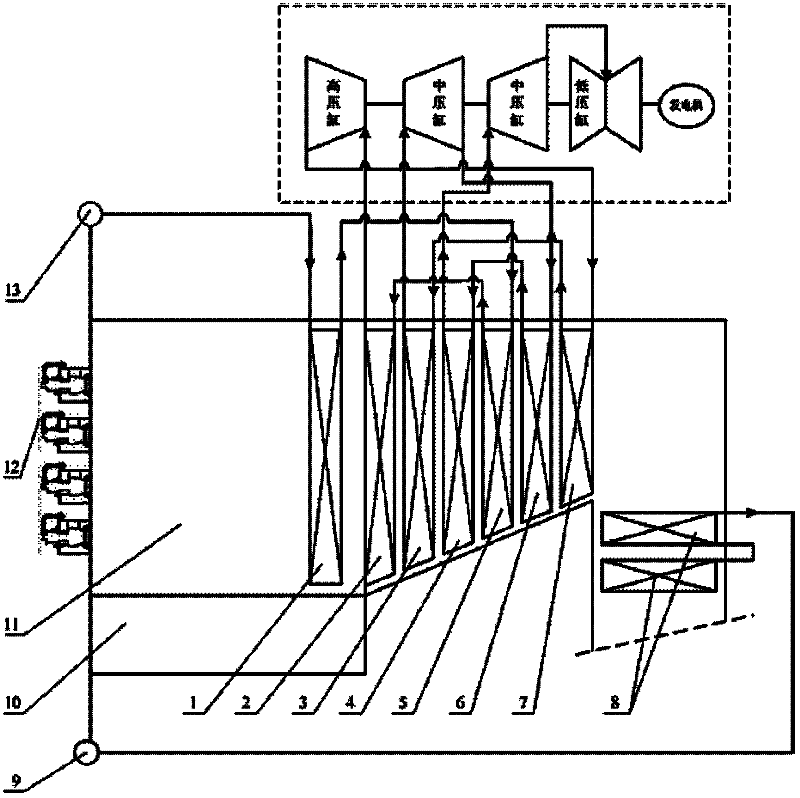

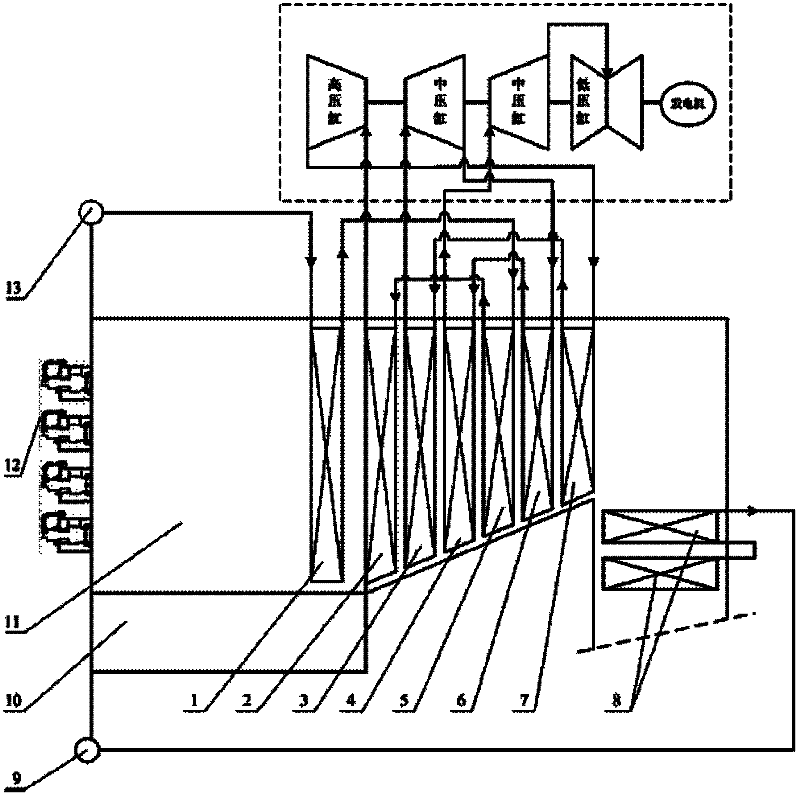

[0016] see figure 1 , the present invention includes a horizontally placed boiler furnace 11 with a cold ash hopper 10 installed at the lower end and a panel superheater 1 arranged in the boiler furnace 11, a burner 12 is arranged on the front wall of the boiler furnace 11, and a boiler horizontal smoke In the duct, there are high-temperature superheater 2, high-temperature primary reheater 3, high-temperature secondary reheater 4, low-temperature superheater 5, low-temperature secondary reheater 6 and high-temperature primary reheater 7 arranged in sequence according to the flue gas flow direction. Two-stage economizers 8 are arranged in the vertical flue at the rear. Boiler steam passes through the panel superheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com