Tube wall overtemperature control method for platen superheater in 1045-megawatt ultra supercritical boiler

A technology for ultra-supercritical boilers and panel superheaters, applied in control systems, lighting and heating equipment, steam generation, etc., can solve problems such as over-temperature explosions and harsh environments, reduce labor intensity, and prevent over-temperature explosions The effect of managing accidents and improving safety and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

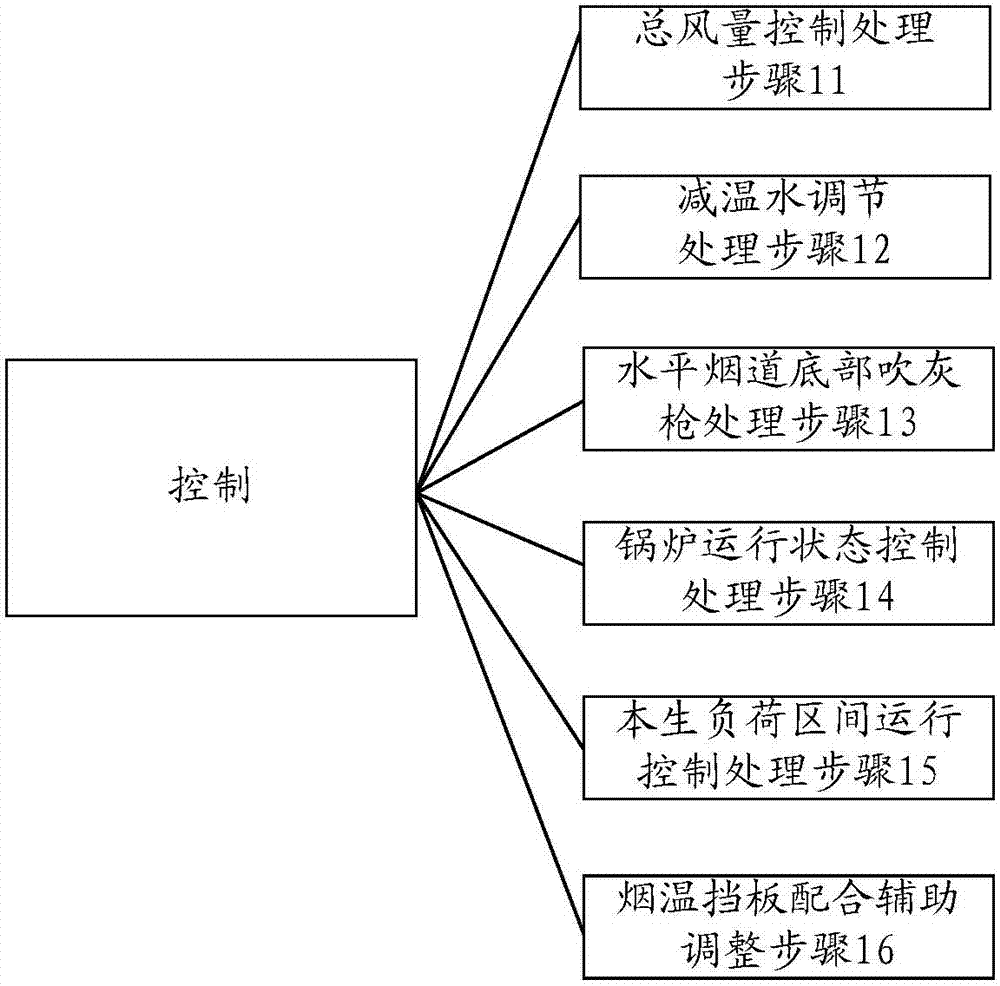

Method used

Image

Examples

Embodiment Construction

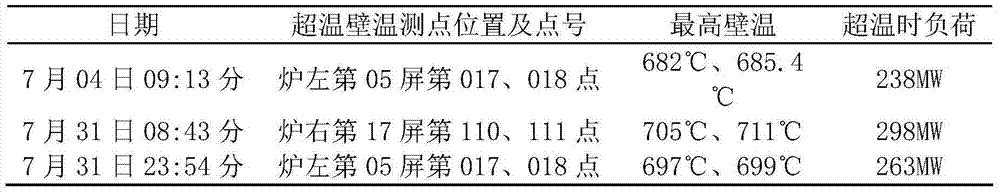

[0018] The present invention can make use of statistics on the overtemperature of the tube wall of the panel superheater in a 1045 megawatt ultra-supercritical boiler, and then perform corresponding overtemperature control. The specific overtemperature statistics can refer to the following table 1:

[0019] Table 1 Statistics of tube wall overheating of panel superheater

[0020]

[0021] Generally, the low load mentioned in the boiler refers to the low load which is lower than 30% of the maximum load. From the above table 1, it can be seen that the overtemperature of the tube wall of the panel superheater in the 1045 MW ultra-supercritical boiler basically occurs at In the load section before and after the dry state of the low-load boiler changes from the dry state to the wet state, and from the wet state to the dry state. In addition, the over-temperature parts are basically concentrated on the fifth screen or the 17th screen. The temperature deviation of the tube wall is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com