Manufacturing method for G115 large-caliber thick-wall seamless steel pipe of 630 DEG C ultra-supercritical unit

A technology of an ultra-supercritical unit and a manufacturing method, which is applied in the field of seamless steel pipe manufacturing, can solve the problems of low impact toughness and the like, and achieve the effects of improving impact toughness and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

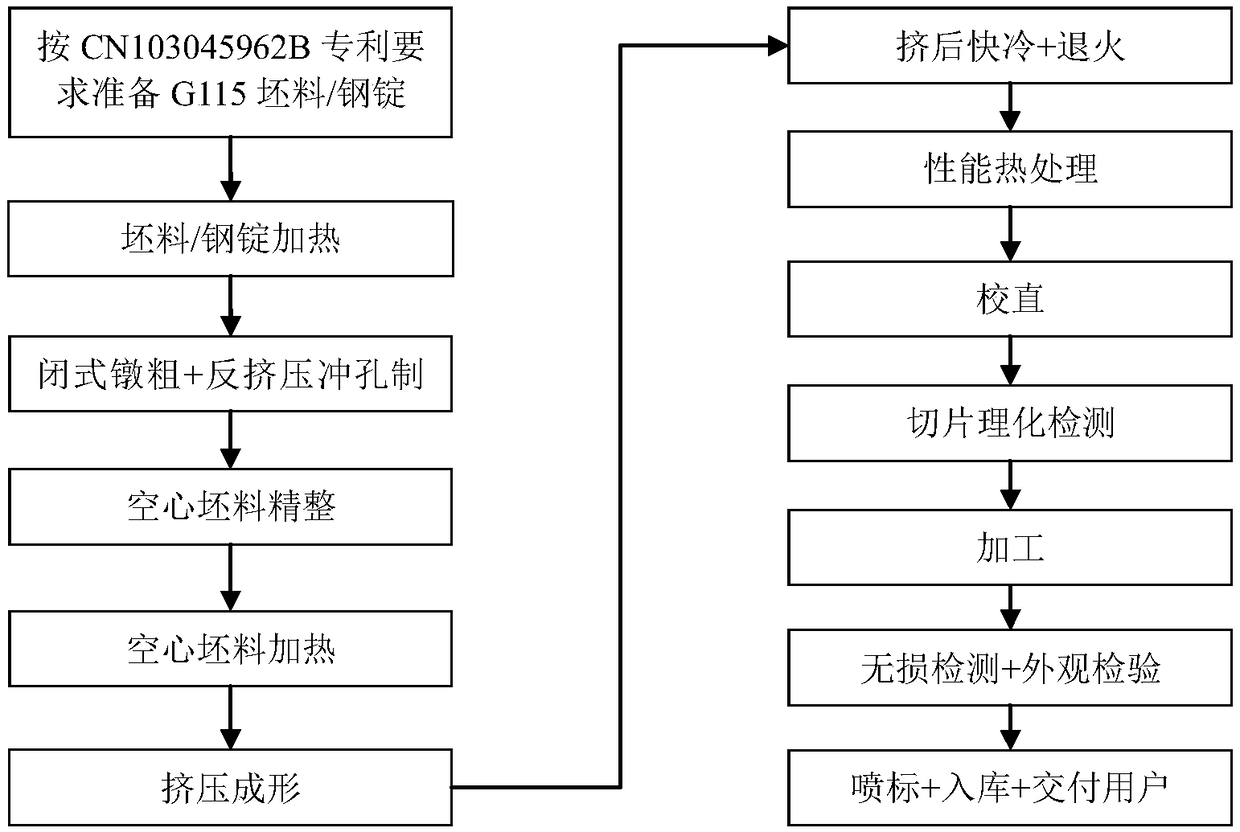

Method used

Image

Examples

Embodiment 1

[0029] Specifications of finished steel pipe: 540mm×70mm×5000mm

[0030] 1. Raw material (forging billet / steel ingot) preparation

[0031] According to the patent of CN103045962B, one billet / steel ingot is prepared, and the ingot weighs 10 tons.

[0032] 2. Use a gas heating furnace to heat the steel ingot to 1140±10°C.

[0033] 3. Closed upsetting + reverse extrusion punching

[0034] Remove the oxide skin on the surface of the steel ingot, spray the glass lubricant on the surface, and then carry out closed upsetting in the billet press with an upsetting ratio of 1.56, reverse extrusion punching, and a perforation ratio of 1.1 to make a hollow billet.

[0035] 4. Extrusion

[0036] Heat the hollow billet to 1240±10°C, remove the oxide skin on the surface of the hollow billet and return to the furnace for 0.5 hours to make up for the temperature loss on the surface of the hollow billet. After spraying the glass lubricant, extrude the hollow billet into a tube billet on the ...

Embodiment 2

[0065] Embodiment 1 Other method steps remain unchanged, and the performance heat treatment in step 6 adopts quenching+tempering method to realize the present invention.

[0066] Quenching temperature: 1070°C±10°C, temperature equalization for 3 hours + heat preservation for 4 hours, water cooling, cooling to room temperature and then tempering.

[0067] Tempering temperature: 790°C ± 10°C, holding temperature for 3 hours + holding for 4 hours and then air cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com