Method for calculating temperature of tube wall of platen superheater of ultra supercritical boiler by assistance of numerical simulation

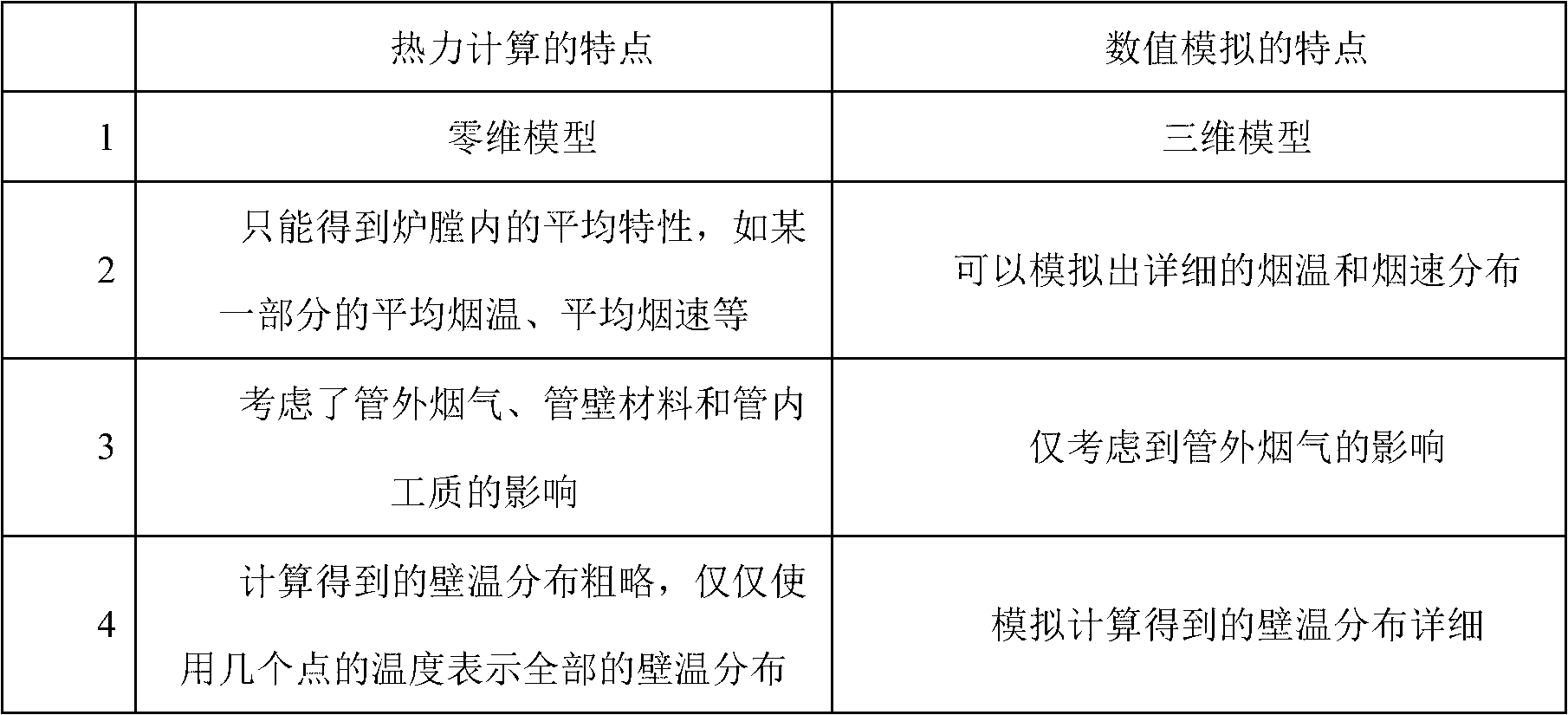

A technology of ultra-supercritical boilers and panel superheaters, which is applied in calculation, instrumentation, and electrical digital data processing, etc., can solve problems such as uneven hydraulic power, heavy workload, and error in wall temperature distribution results, so as to improve calculation speed, Good combination and utilization, high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

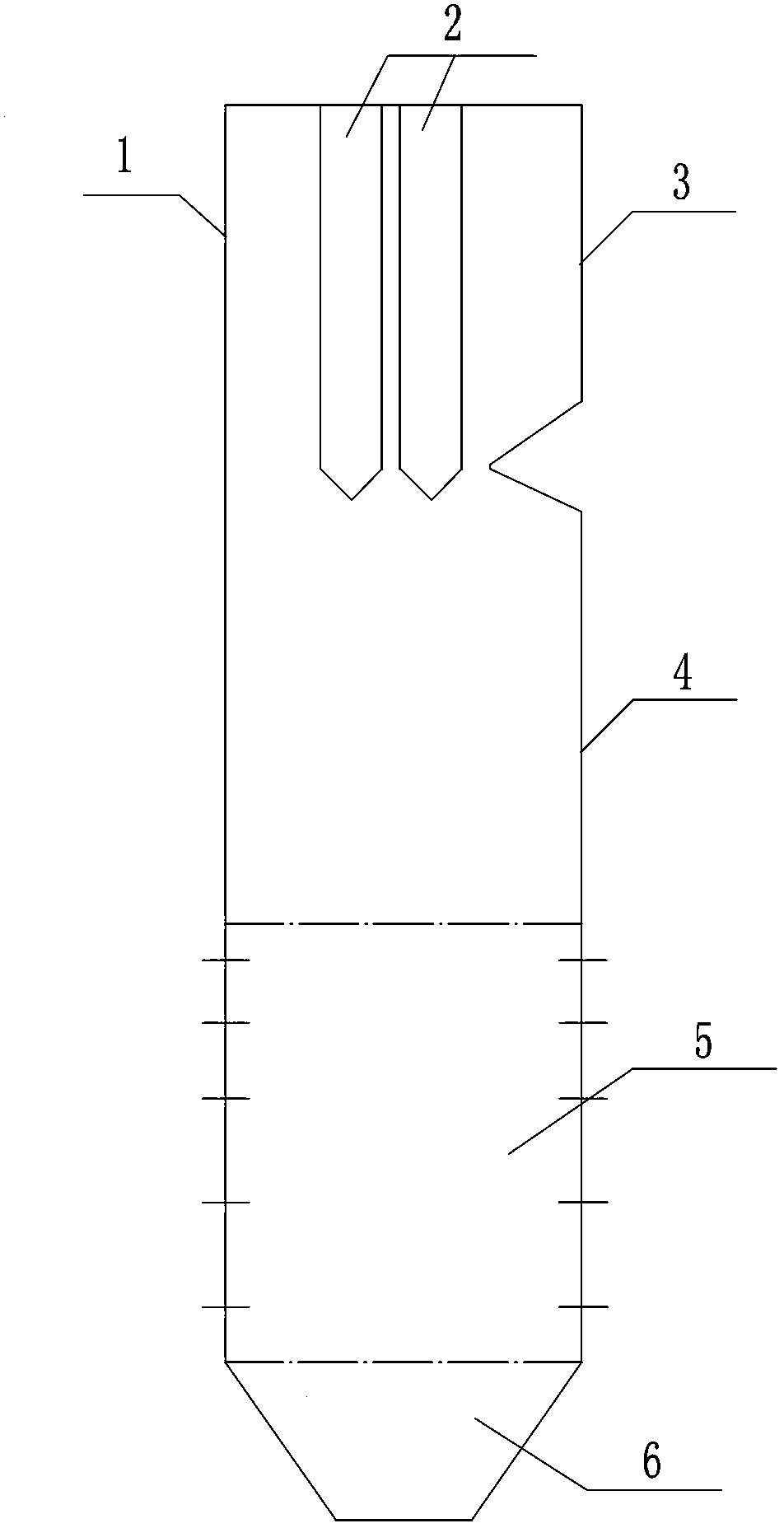

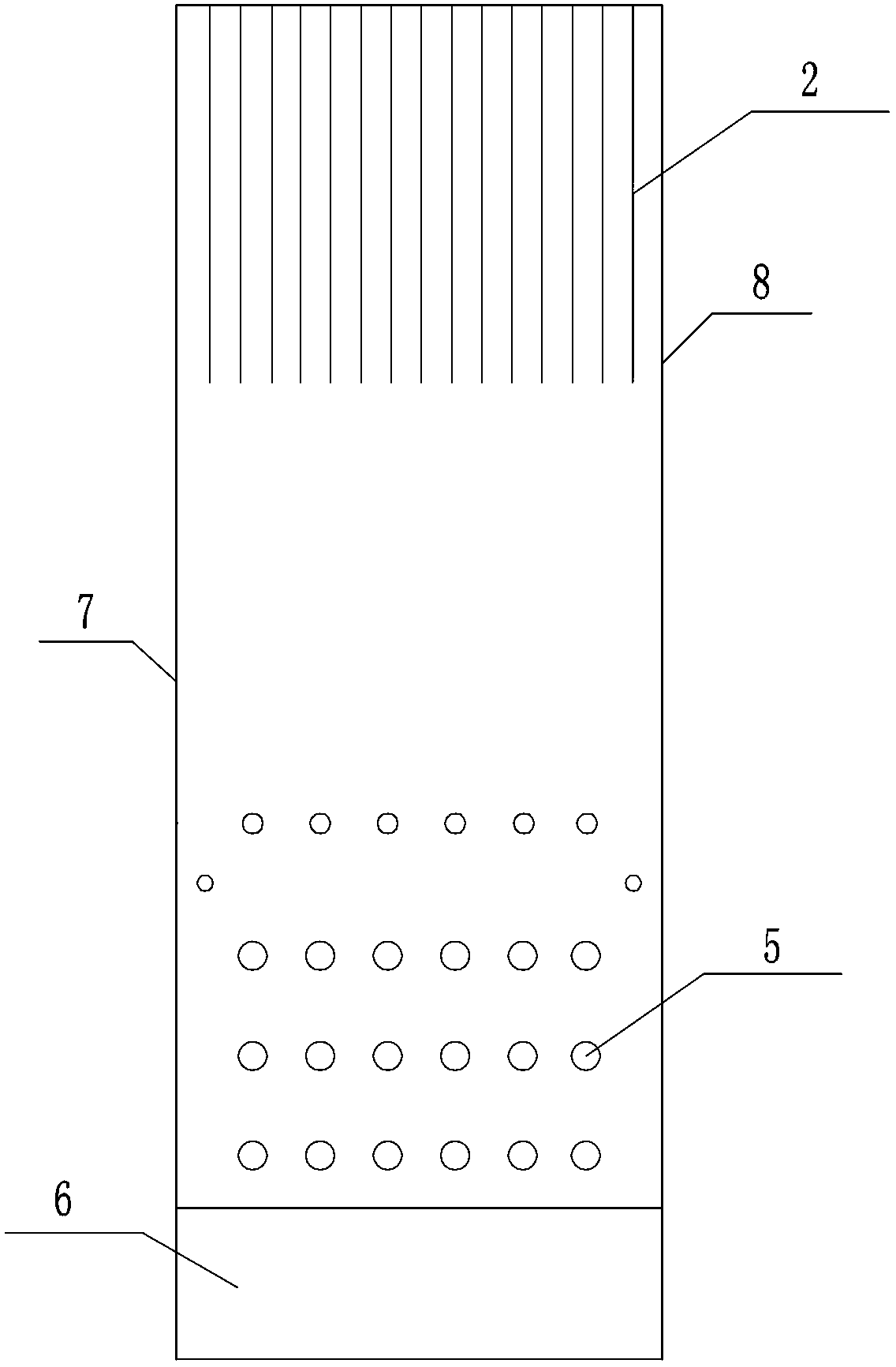

[0038] The present invention uses numerical simulation to assist the calculation method of the tube wall temperature of the panel superheater of an ultra-supercritical boiler. figure 1 , figure 2 The boiler structure diagram is used for modeling, and its calculation flow chart is shown in Figure 3. The calculation method includes the following steps:

[0039] Ansys 12.0 is designed for unstructured grid models. It is a software for solving incompressible flow and moderately compressible flow field problems with finite elements. It has certain requirements for the quality of the divided grid. Compared with the entire furnace, the swirl burner is not only very small in size, but also irregular in structure. If the swirling burner and the furnace are considered as a whole when modeling, the quality of the divided grid is poor, and the energy conservation equation, mass conservation equation and momentum conservation equation are prone to calculation errors during simulation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com