General hydrodynamic calculation method for ultra-supercritical boiler

A technology of ultra-supercritical boiler and calculation method, which is applied in the direction of calculation, special data processing application, instrument, etc., can solve the problems of hydrodynamic calculation difficulty of ultra-supercritical boiler, limiting the scope of application of the model, affecting the accuracy of the model, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

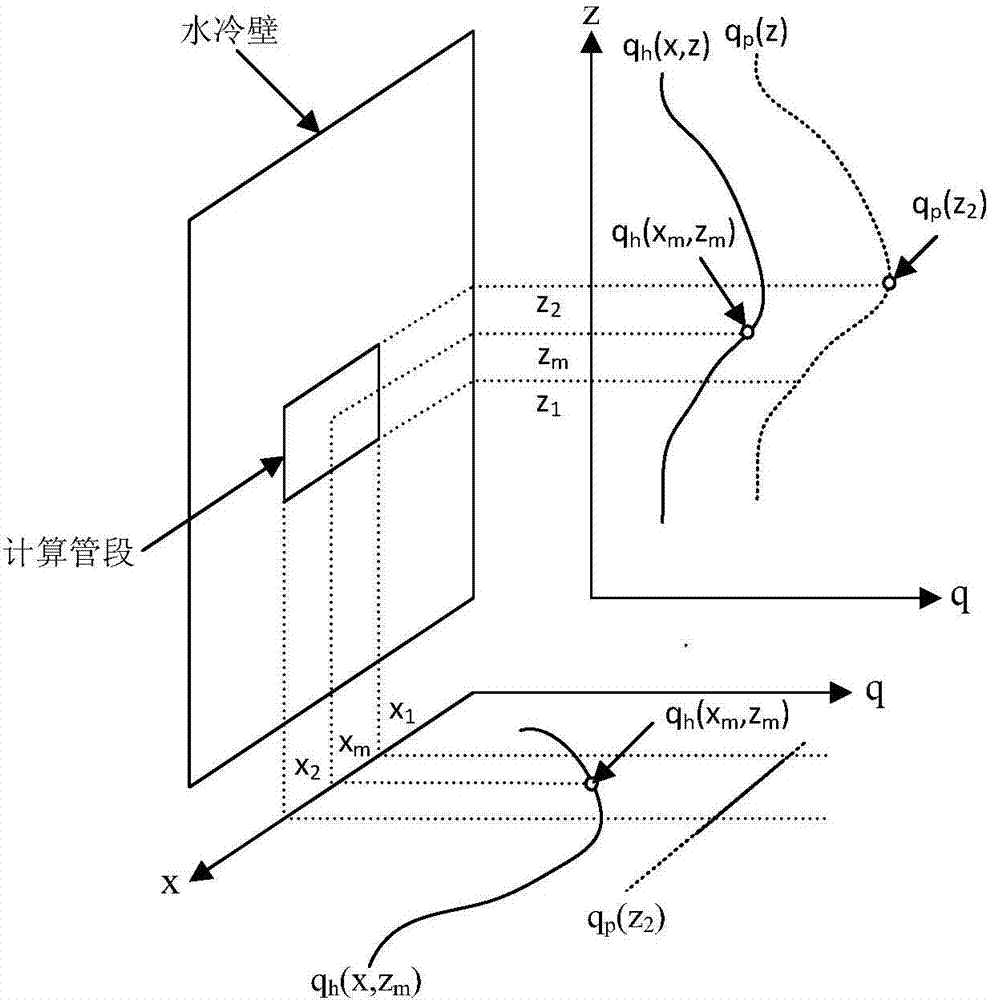

[0071] 1. Divide circuits and pipe sections:

[0072] Circuit division: The geometric structure and heat absorption of the tubes that make up the water wall of the boiler are different, and there are structural deviations and thermal deviations. Adjacent tubes with basically the same geometric structure and heat absorption deviation are divided into the same circuit, and the thermal parameters and geometric structures of each single tube are considered to be exactly the same. At the same time, in the part where the heat absorption deviation changes significantly in the horizontal direction of the furnace or the geometric structure changes greatly, the circuit division should be dense, and the number of distribution pipes corresponding to each circuit is small, while in the area where the heat absorption deviation or geometric structure changes gently, the circuit division should be It can be relatively sparse, and the number of pipes corresponding to each circuit is relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com