Tube wall overtemperature control method for platen superheater in 1045-megawatt ultra supercritical boiler

A technology of ultra-supercritical boiler and screen superheater, which is applied in the control of superheat temperature, control system, and steam superheating, etc., can solve the problems of over-temperature pipe explosion and harsh environment, reduce labor intensity, avoid influencing factors, The effect of flow deviation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

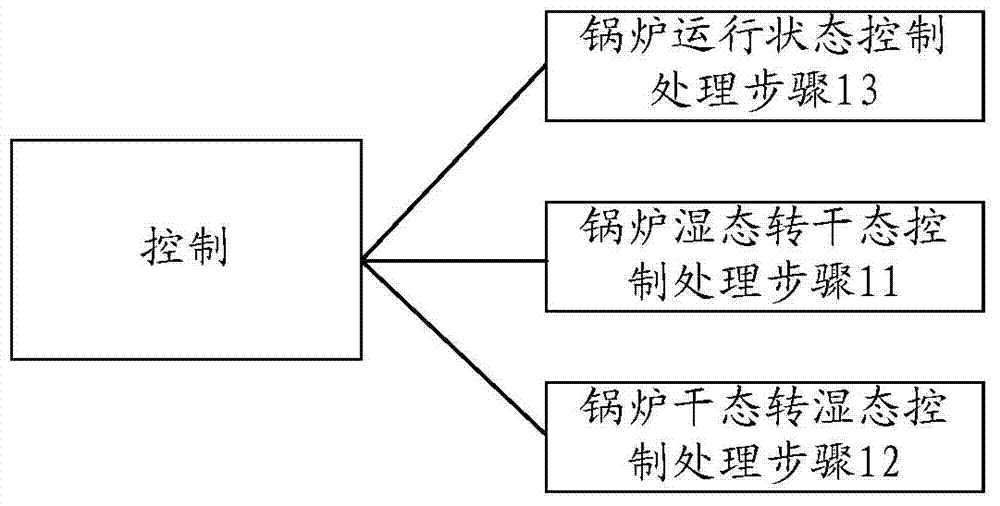

[0021] During the operation of the 1045 MW ultra-supercritical boiler, due to the influence of the physical characteristics of the working fluid, during the conversion process of the dry-wet state of the Bunsen load, the parameters such as steam specific volume fluctuate greatly, causing the flow deviation between the tubes to increase. Specifically, The variable load operation of the 1045 MW ultra-supercritical boiler in the present invention mainly goes through two special stages: one is the transformation process of the boiler from wet operation to dry operation, which is mainly reflected in the subcritical pressure of the working medium in the water-cooled wall tube, The steam-water mixture with a large steam content is converted into dry steam with a certain degree of superheat. During this stage, the steam-water specific volume changes greatly. Due to the uneven flow distribution and the sharp drop in the temperature conductivity of the working medium, it is very easy to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com