Start calculation method and system for supercritical boiler

A technology of supercritical boilers and calculation methods, which is applied in calculation, design optimization/simulation, special data processing applications, etc., and can solve problems such as large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

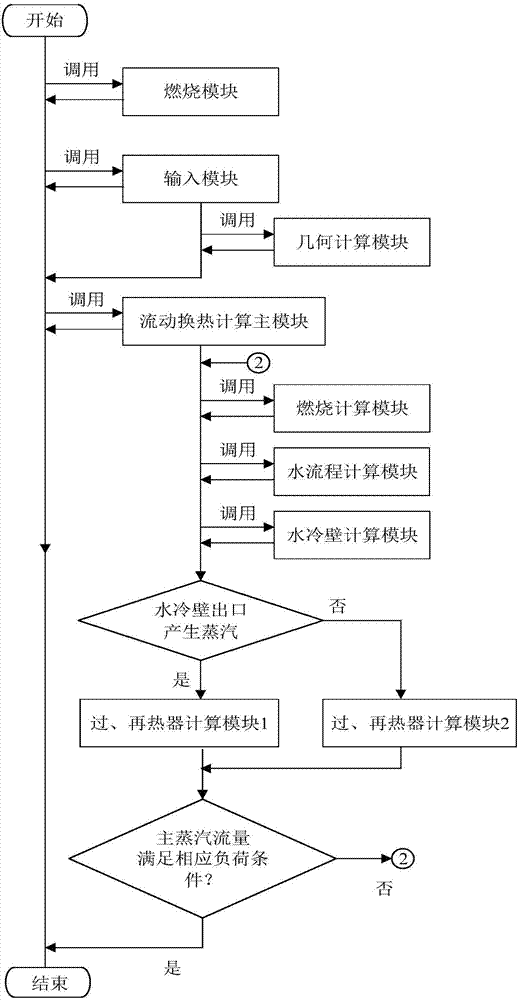

[0111] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0112] A start-up calculation method for a supercritical boiler, the steps are as follows:

[0113] 1) Furnace combustion calculation: In order to calculate the flue gas temperature, flow rate, density and specific heat at the furnace outlet under different combustion rates during the start-up process, the furnace is divided into two parts: the radiation heat exchange area and the radiation convection area. The radiation heat transfer zone is the area between the bottom of the furnace and the burner, and the heat transfer method is radiation heat transfer, without considering the convective heat transfer between the flue gas and the furnace wall. The radiation convection area is the part above the radiation heat exchange area to the furnace outlet. The heat transfer between the flame and the water wall in this area is mainly radiation heat exchange, and the convective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com