Peak-regulating power station integrating IGCC and supercritical unit, and peak regulating method

A technology for supercritical units and peak-shaving power stations, which is applied in the direction of mechanical equipment, steam engine installations, and combined combustion mitigation. Load stability and peak shaving capability, saving fuel consumption, realizing the effects of power generation efficiency and environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

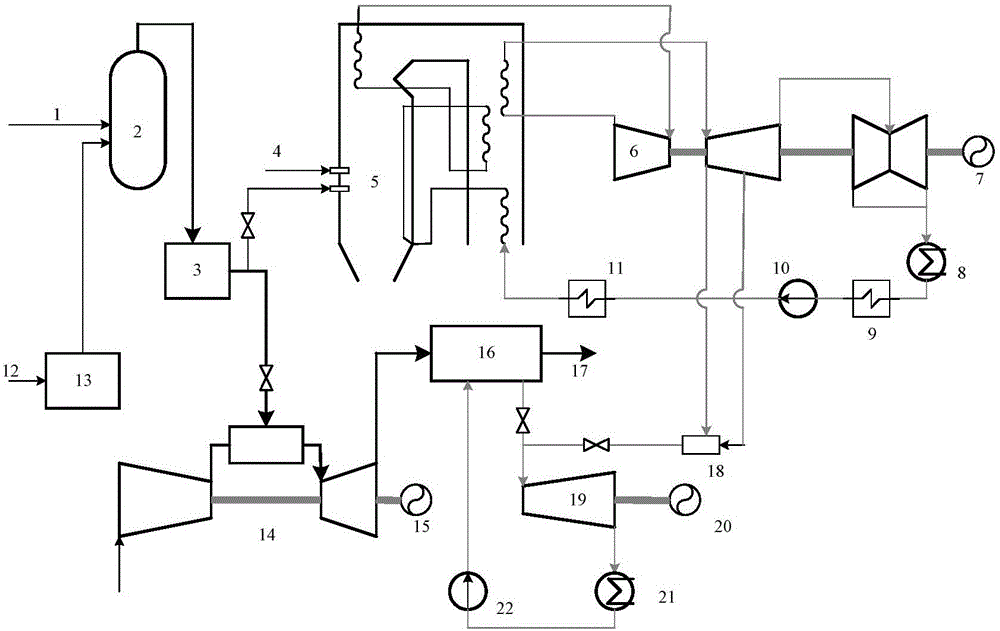

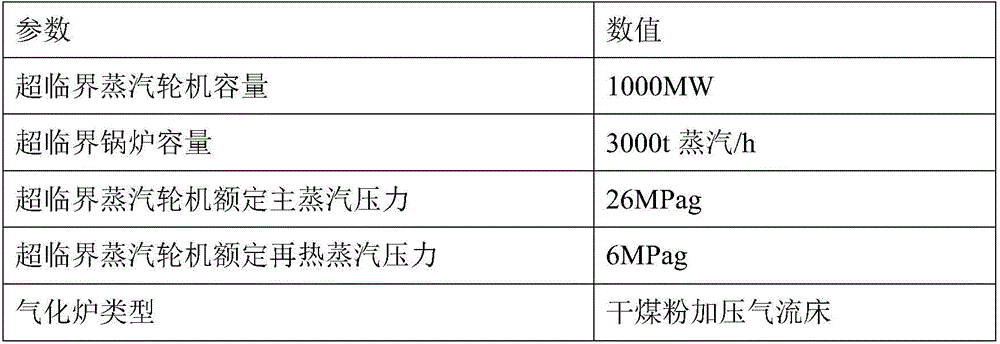

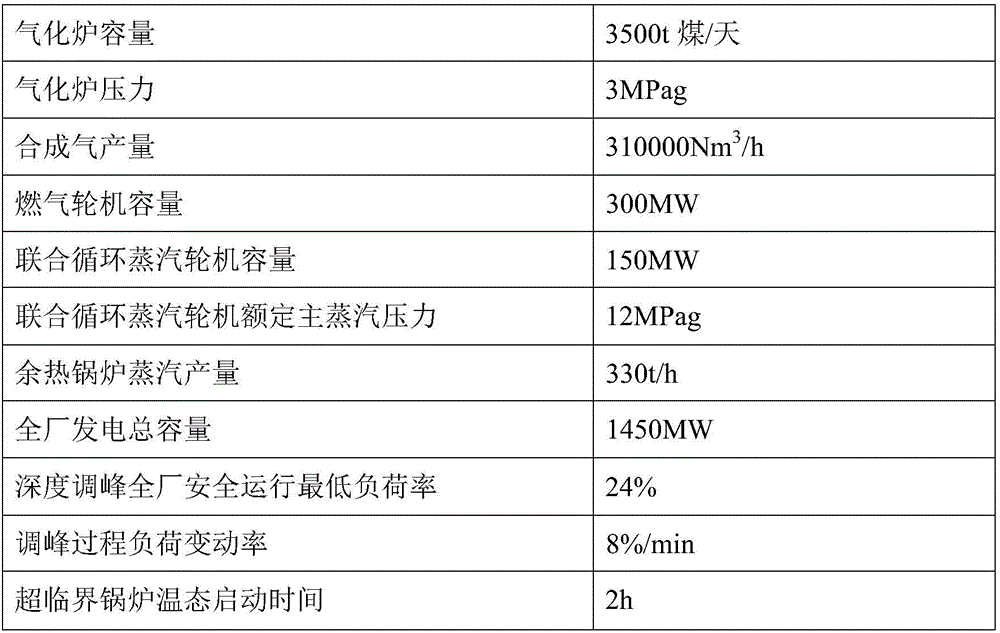

[0025] see figure 1, a peak-shaving power station integrating IGCC and supercritical units, including IGCC generating units and supercritical generating units, characterized in that the outlet of the gasifier 2 in the IGCC generating units is connected to the inlet of the synthesis gas of the purification unit 3, and the purified The outlet of unit 3 is divided into two paths, one path is connected to the combustion chamber of the gas turbine 14, and the load of the peak-shaving power station can be quickly changed by adjusting the intake amount of the synthesis gas of the gas turbine 14, and the other path is connected to the synthesis gas of the supercritical boiler 5 in the supercritical generating set Burner; the supercritical boiler 5 receives synthesis gas for ignition and start-up, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com