Self-adaptive correcting method for dynamic accelerating feedforward of supercritical boiler

A supercritical boiler and dynamic acceleration technology, which is applied to lighting and heating equipment, steam generation, control systems, etc., to achieve the effect of improving compensation accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

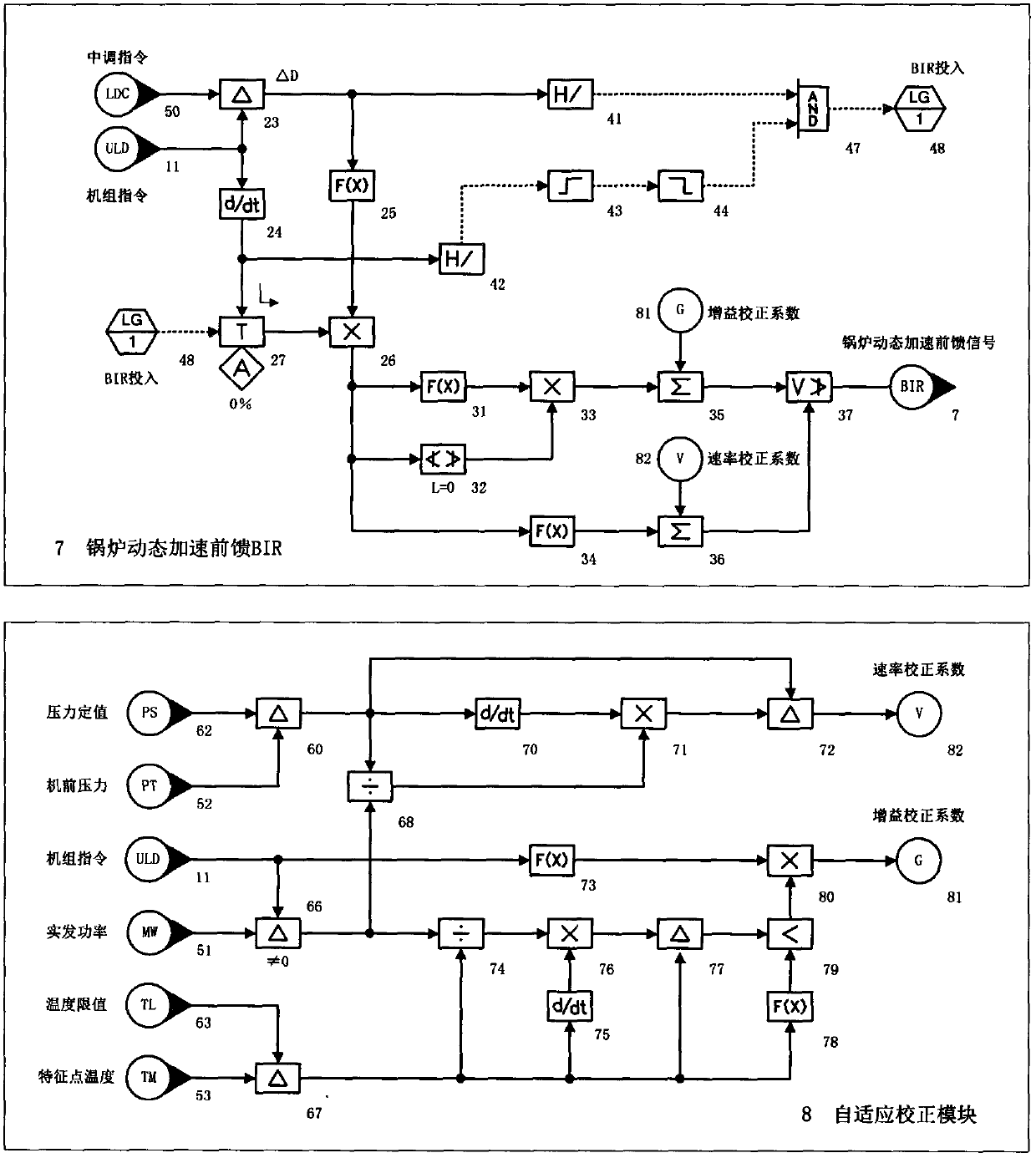

[0029] Attached below Figure 1 ~ Figure 3 Let's describe in detail the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention and provides specific implementation methods and system structures, but the protection scope of the present invention is not limited to the following embodiments.

[0030] The 1000MW ultra-supercritical thermal power generating unit boiler of a power plant adopts the ultra-supercritical parameter coal-fired tower once-through boiler designed and manufactured by Shanghai Boiler Factory Co., Ltd. with the introduction of Alstom technology. The steam turbine and unit unit distributed control system DCS adopt the Ovation system of Emerson Corporation of the United States.

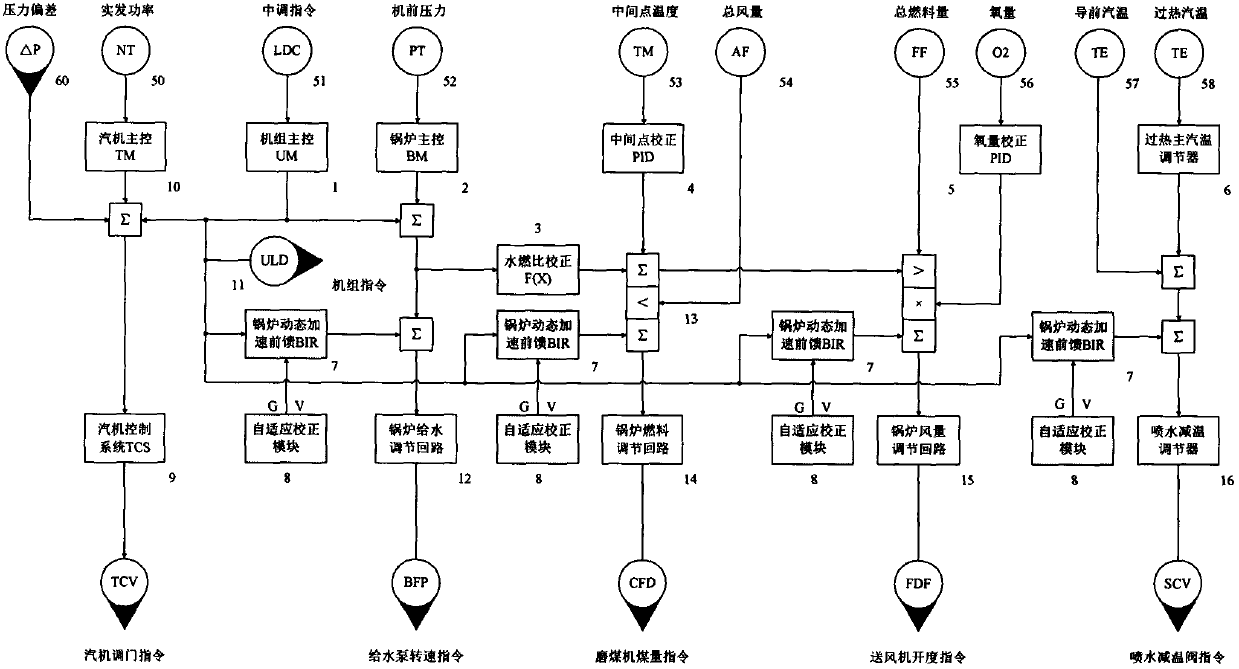

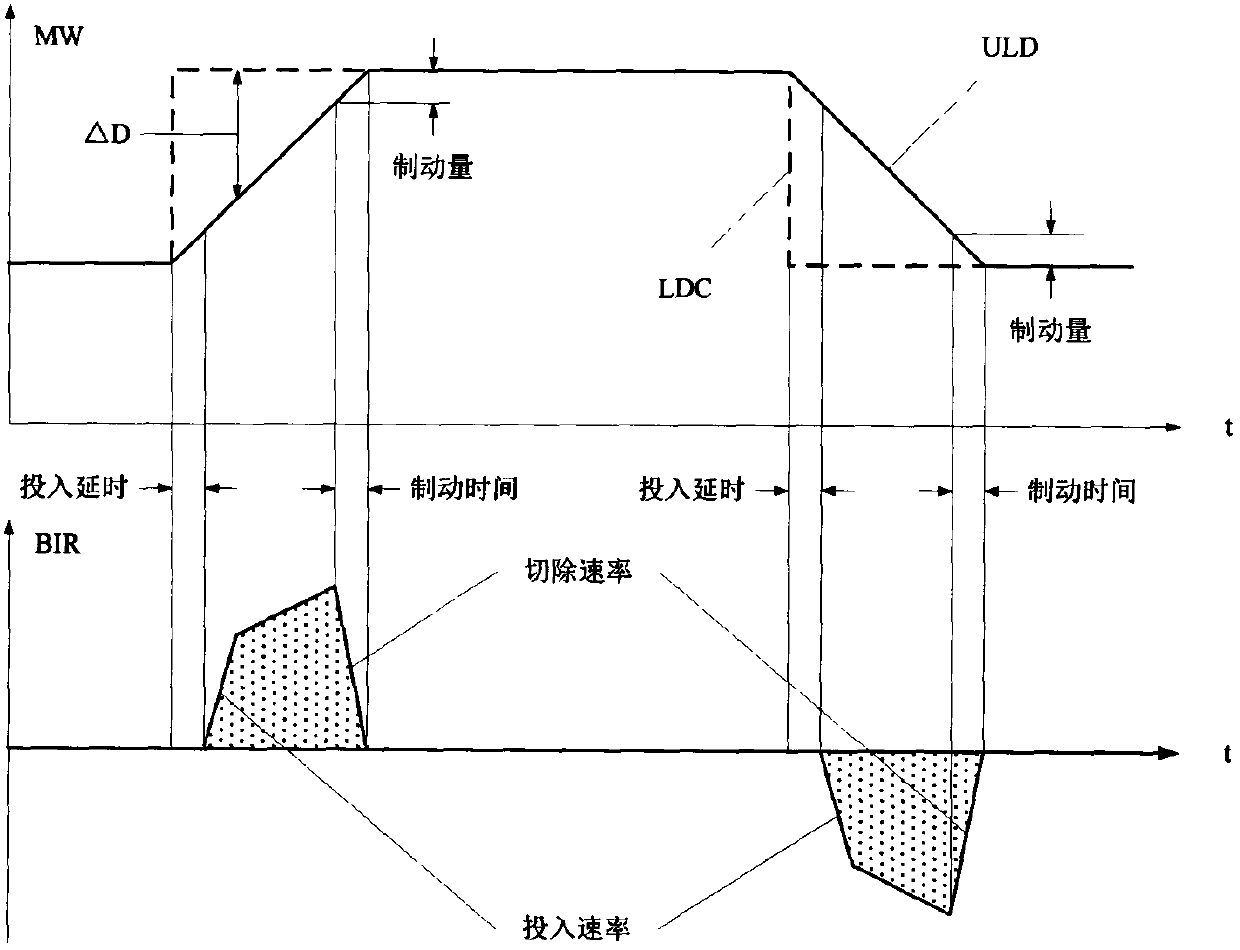

[0031] The method of the present invention is now used in the Ovation system to optimize and modify the control logic of the coal-fired ultra-supercritical boiler control strategy of the original Alstom typi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com