Ultra-supercritical boiler heating-surface wall-temperature monitoring system and monitoring method

An ultra-supercritical boiler and monitoring system technology, applied in the field of boiler manufacturing, can solve the problems of thermocouple length and price, and achieve the effect of increasing reliability, reducing length, increasing reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

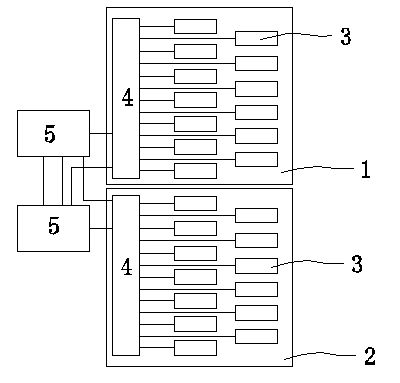

[0025] An ultra-supercritical boiler heating surface wall temperature monitoring system of this embodiment, see figure 1 , Monitor the heating surface wall temperature of No. 1 boiler 1 and No. 2 boiler 2 at the same time, the thermocouple 3 on each pipeline of the middle panel superheater and final superheater of No. 1 boiler 1, No. 2 boiler 2 and two data respectively The acquisition system 4 is connected, and the two data acquisition systems 4 are respectively connected to two industrial computers 5 that are mutually redundant.

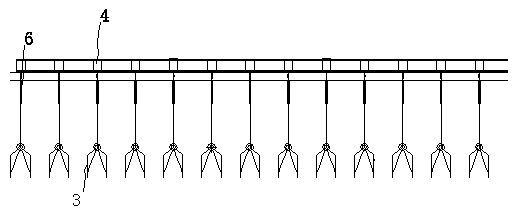

[0026] See figure 2 , The thermocouple 3 on a certain tube panel is distributed along the width of the furnace, and the thermocouple 3 is installed on the top of the furnace. After passing through the sleeve 6, the thermocouple 3 is arranged in sequence with the data acquisition system 4 in the order of the thermocouple 3 along the width of the furnace. Connected; in this embodiment, the length of the thermocouple 3 installed in the panel superheater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com