Refrigeration system with bypass subcooling and component size de-optimization

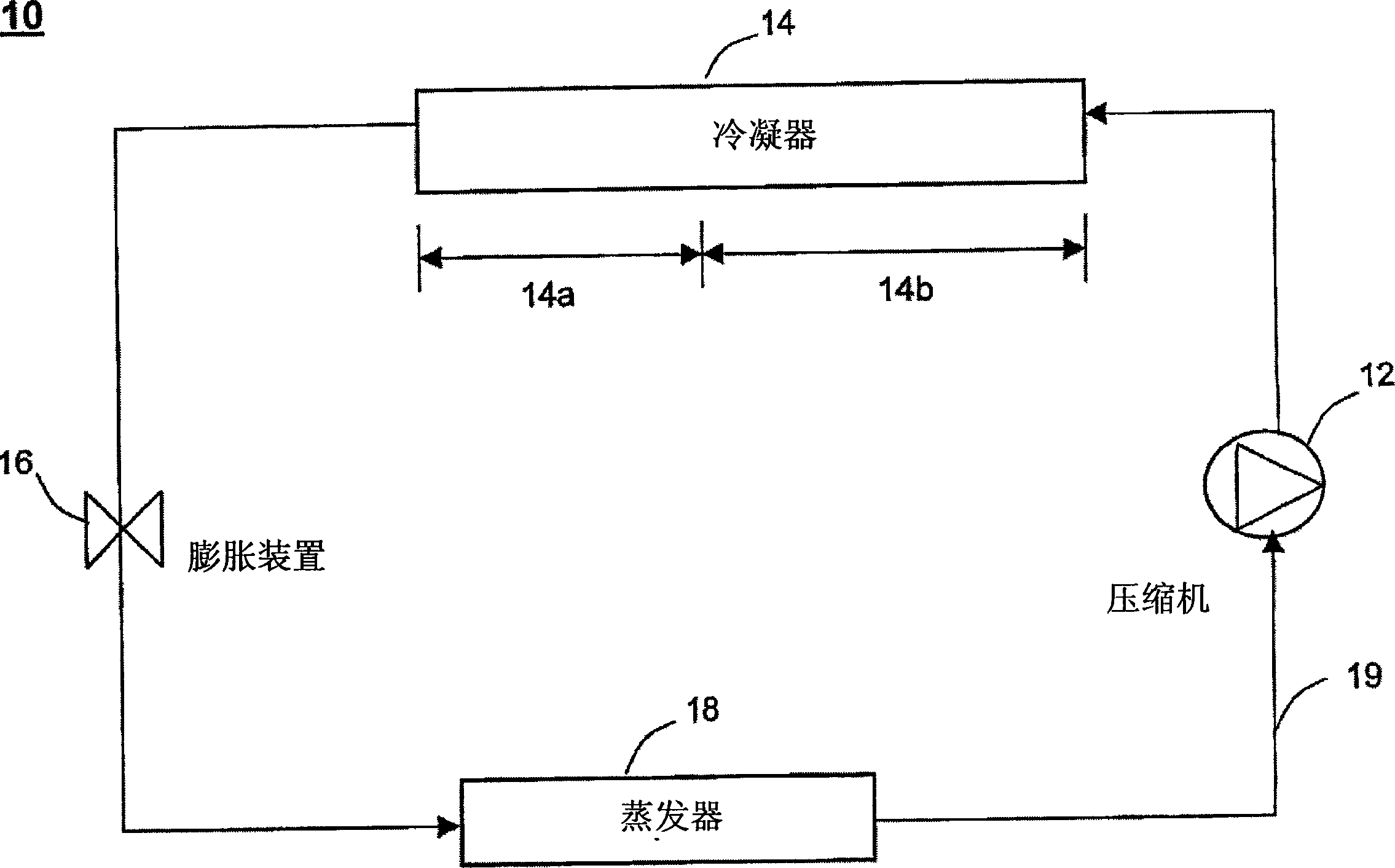

A refrigeration system and component technology, applied in the field of high-efficiency refrigeration systems, can solve the problems of small improvement of mixed refrigerants, high-pressure performance, and limited practical attention, and achieve the effects of improving EER, reducing space, and reducing system costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

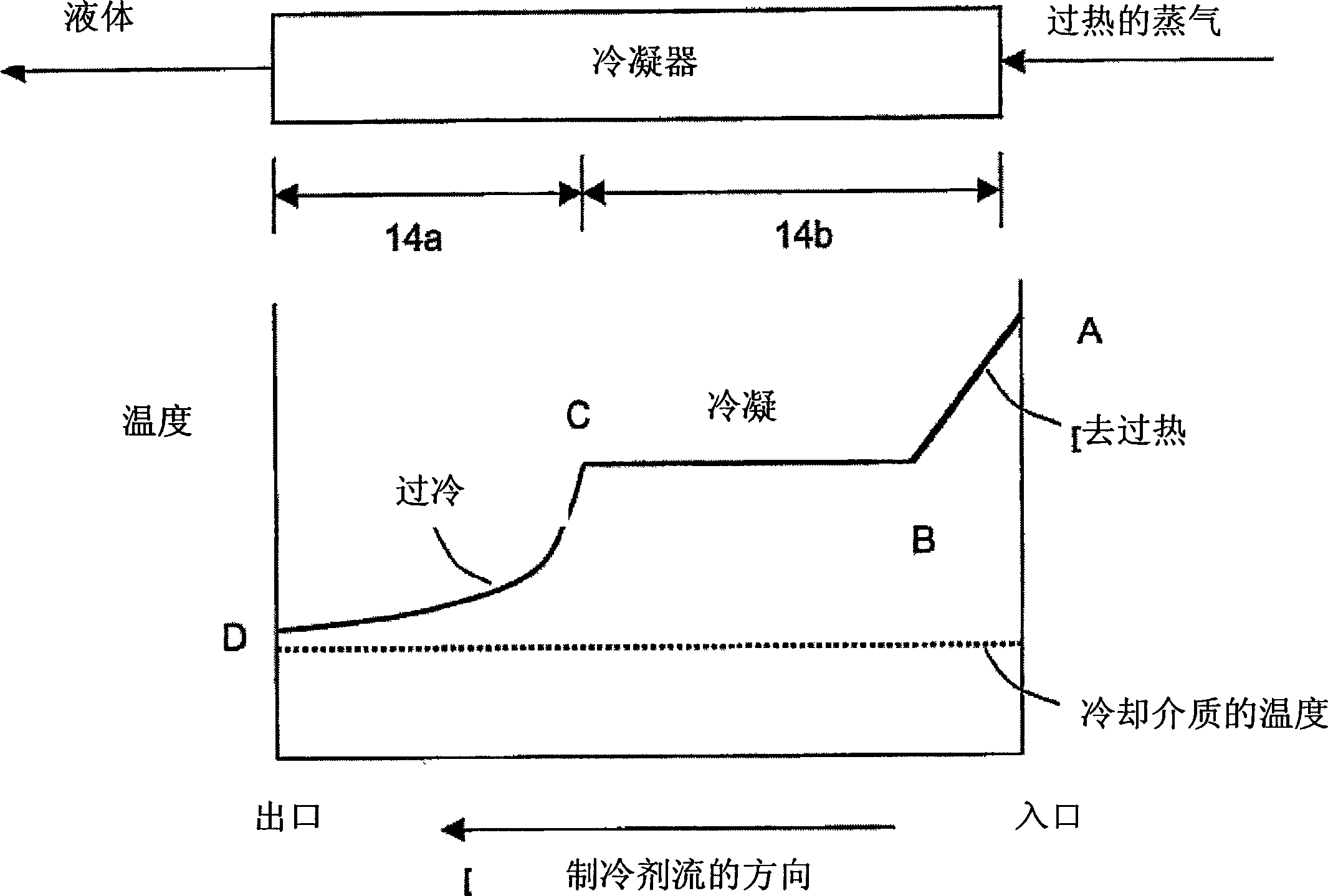

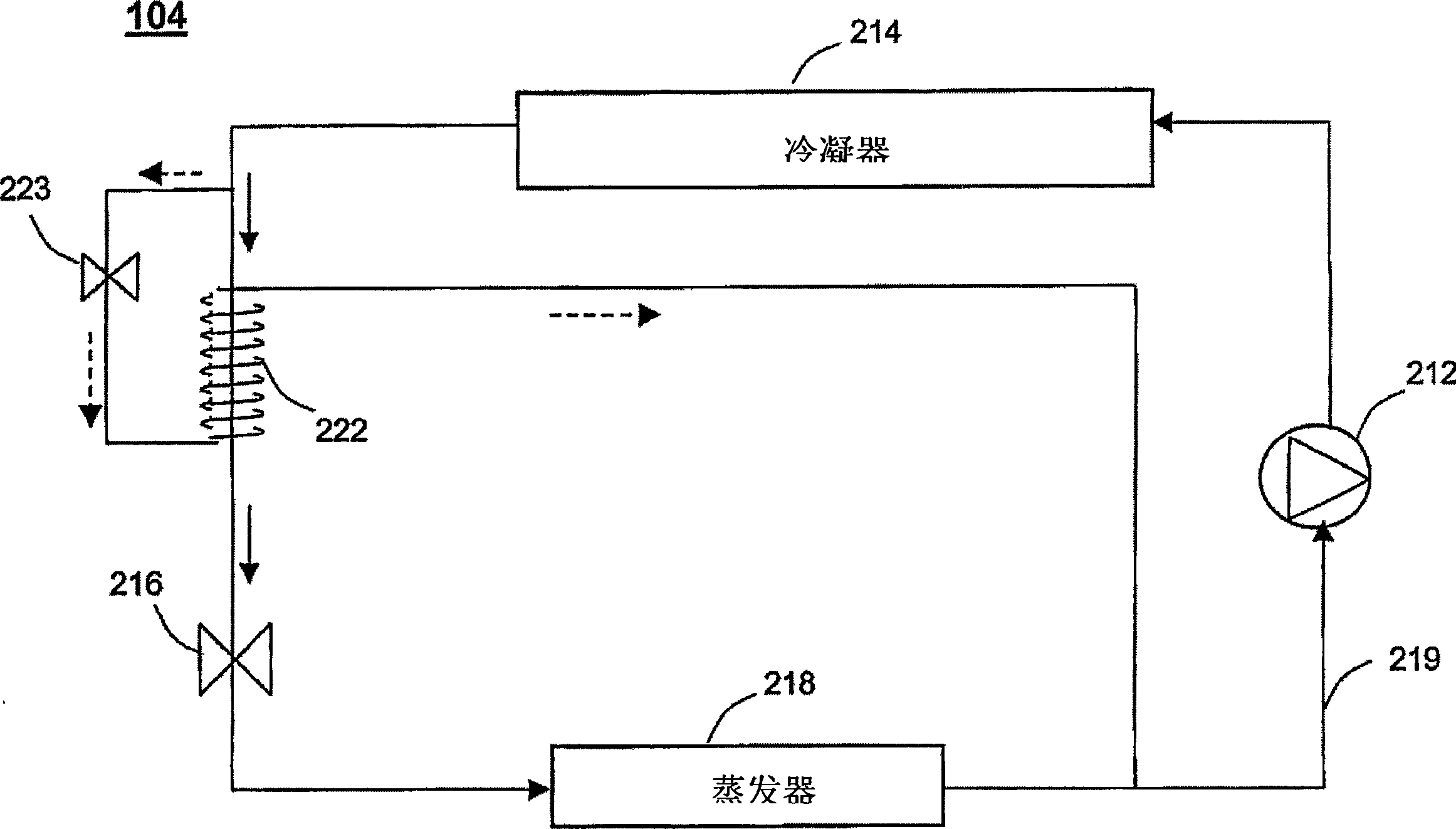

[0064] Figure 5The principle of the bypass technique is shown, where a portion of the liquid refrigerant bypasses through a bypass line or passage 27 . The refrigerant in the bypass line flows through the secondary expansion device 23, thus reducing its pressure and temperature. The cold refrigerant mixture after the secondary expansion device receives thermal energy from the hot liquid refrigerant that has left the condenser and flows through the primary refrigerant circuit while generating additional subcooling in the liquid refrigerant. The additional subcooling resulting from this bypass method makes the subcooling process in the condenser unnecessary. therefore, Figure 5 A smaller condenser 14b is shown with its subcooling section removed and indicated by a dashed rectangular box.

[0065] Figure 6 indicated that the bypass technique used larger evaporators than in an optimized system without bypass technique. Larger evaporators can be used due to the increased su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com