Wall enclosure superheater for supercritical circulating fluid bed (CFB) boiler and wall enclosure method

A superheater and supercritical technology, which is used in steam superheating, lighting and heating equipment, steam generation, etc., can solve the problems of high total resistance, high flow resistance, and limited number of pipes in the intermediate partition wall of the wall-clad superheater system. Achieve the effect of controllability, stable water circulation system, and reduced mass flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

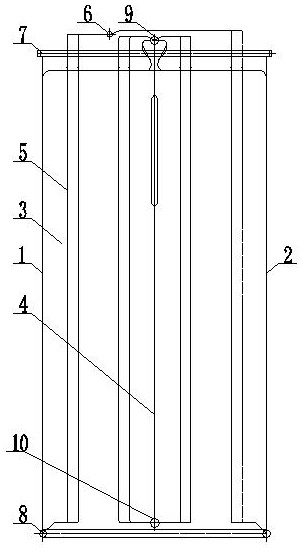

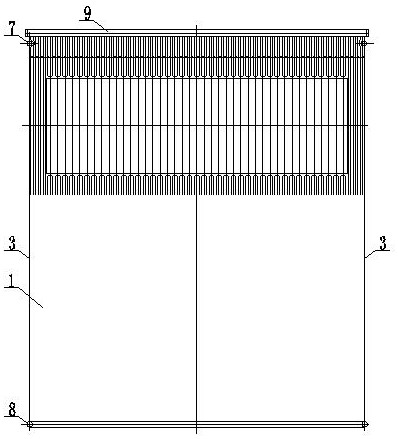

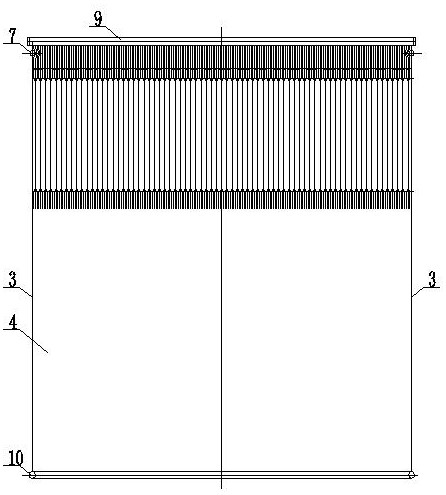

[0021] A wall-enclosed superheater for a supercritical CFB boiler, said wall-enclosed superheater for a supercritical CFB boiler comprising a front wall-enclosed superheater 1, a rear wall-enclosed superheater 2, a side wall-enclosed superheater 3, Intermediate partition wall superheater 4, superheater suspension pipe 5, suspension pipe upper header 6, side wall header 7, wall lower header 8, front and rear wall headers 9, and middle partition wall lower header box 10;

[0022] The superheater suspension pipes are arranged in four rows in the tail flue: the two rows of suspension pipes close to the front and rear wall superheaters are connected in parallel with the side wall to form a group in the wall superheater system Downward loop; two rows of hanging pipes close to the middle partition wall superheater are connected in parallel with the middle partition wall superheater to form another set of downlink loops in the wall-wrapped superheater system; the front and rear wall-w...

Embodiment 2

[0024] According to the wall-enclosed superheater for a supercritical CFB boiler described in Example 1, the two sets of downlinks and one set of uplinks are connected in series through headers to finally form a wall-enclosed superheater system.

Embodiment 3

[0026] A wall-wrapping method for a wall-wrapped superheater of a supercritical CFB boiler, the method includes the following steps: the superheated steam drawn from the steam-cooled separator first enters the upper header of the hanging tube and the side wrap at the top of the tail flue The header on the wall goes down to the lower header of the wall through the side wall and the two-way hanging pipes close to the front and rear walls, and then goes up to the header on the front and rear walls through the superheaters of the front and rear walls (the middle header on the partition wall), and finally, go down through the middle partition wall and two rows of hanging pipes close to the middle partition wall, and enter the lower header of the middle partition wall (the inlet of the low-temperature superheater), and introduce the superheater to the low-temperature superheater to complete The entire process of the superheater in the wall superheater is understood.

[0027] The boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com