Supersonic Cooling With Pulsed Inlet and Bypass Loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

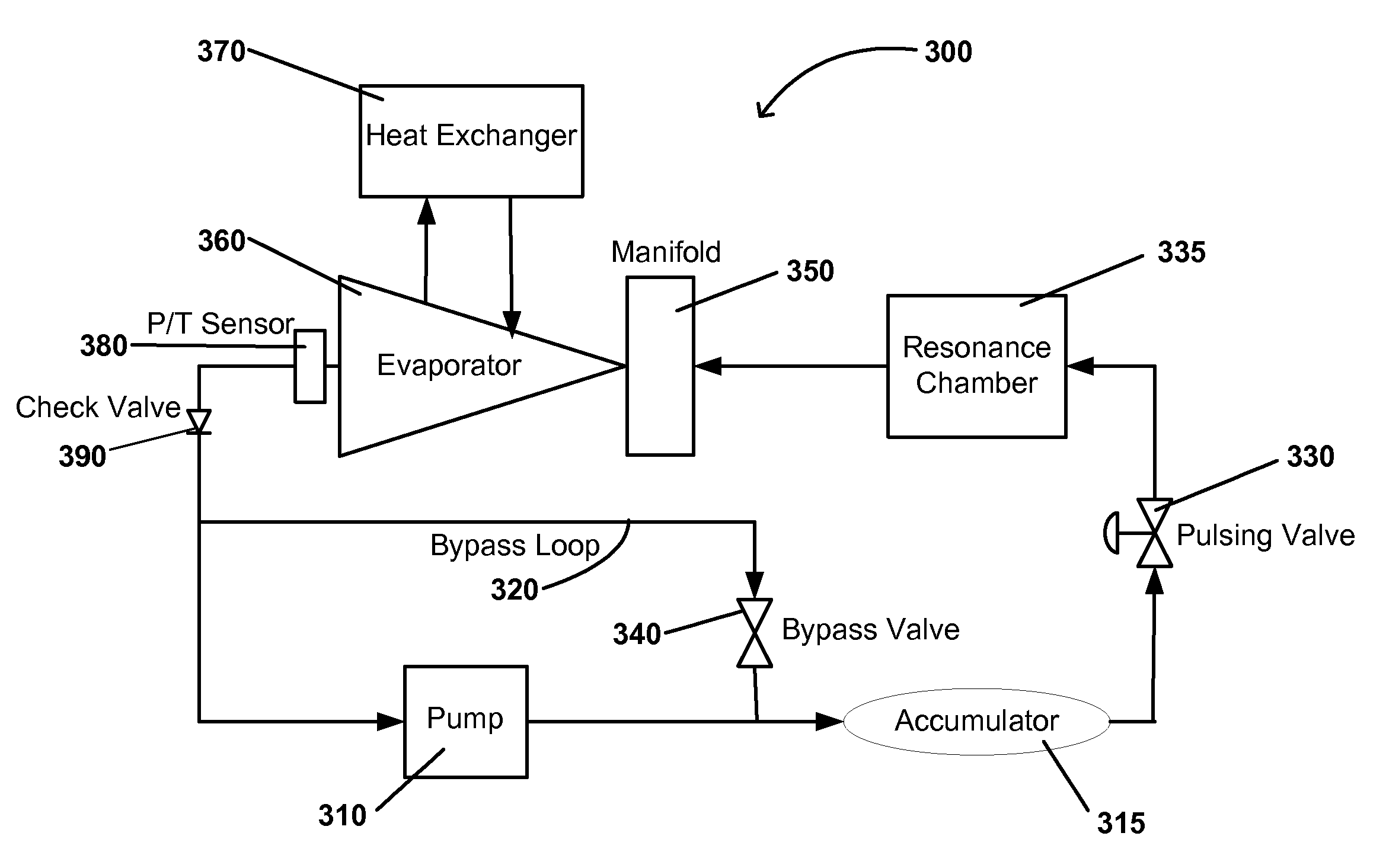

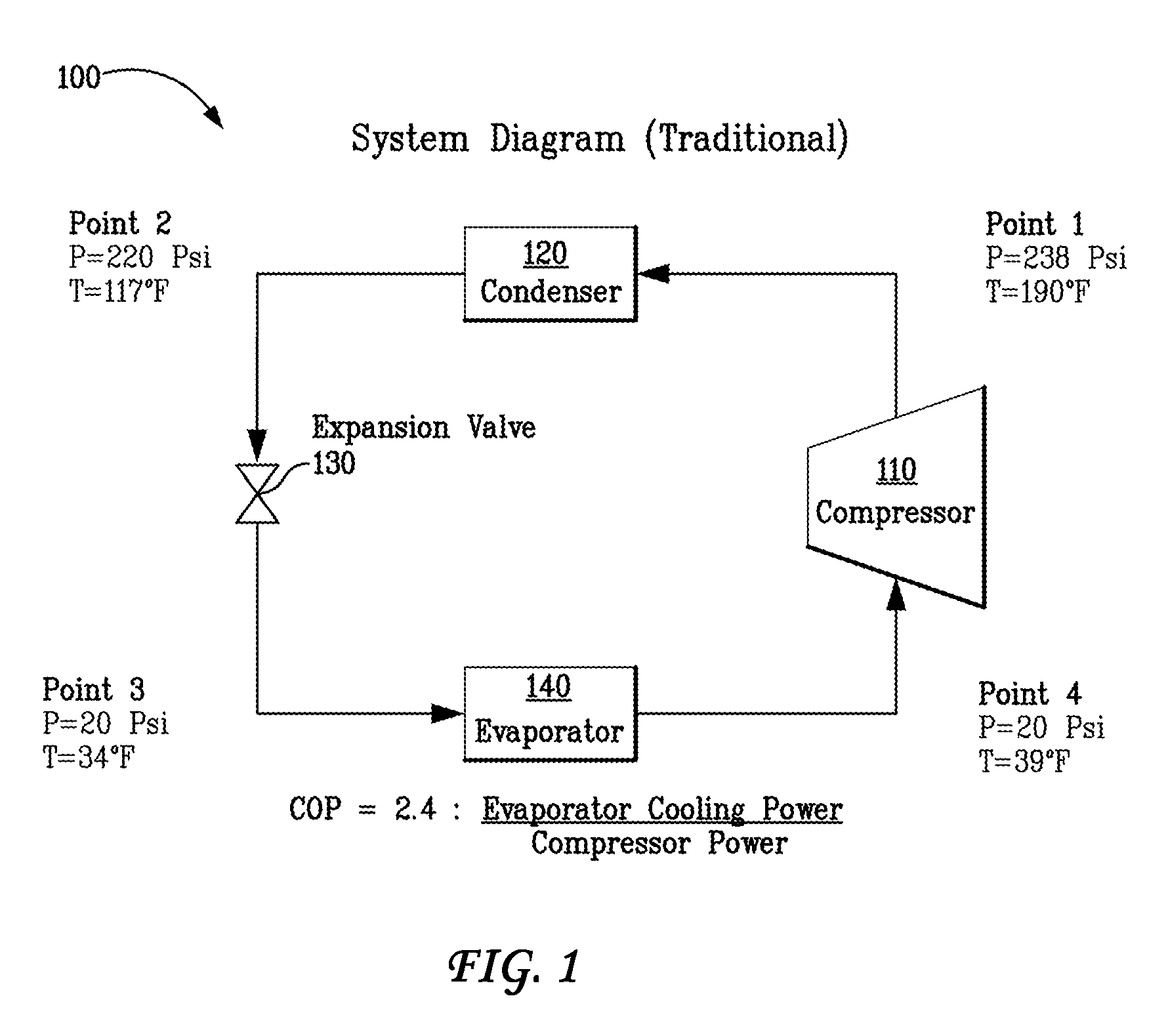

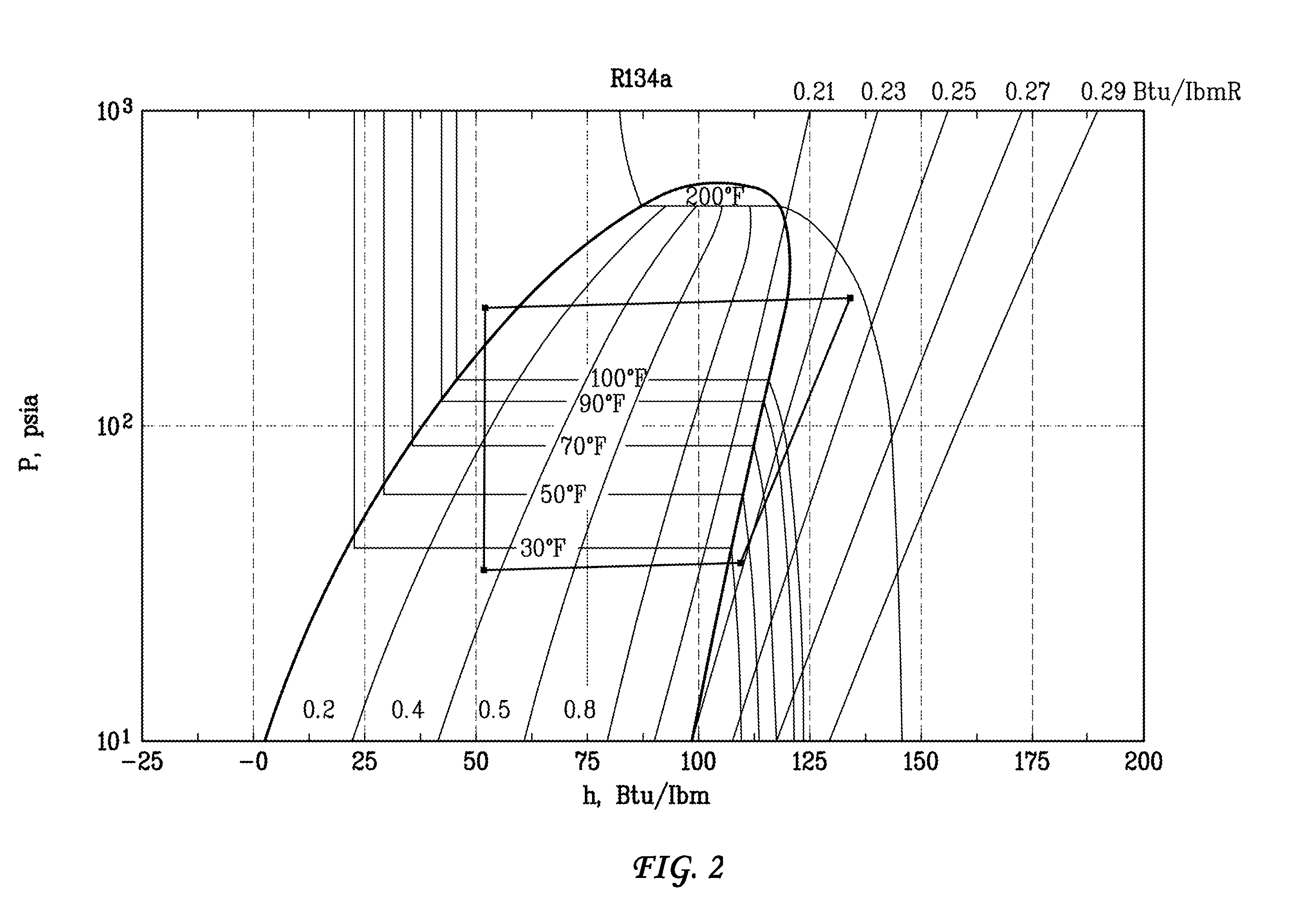

[0021]FIG. 3 illustrates an exemplary supersonic cooling system 300 in accordance with an embodiment of the present invention. FIG. 4 illustrates a pressure-enthalpy graph for a supersonic cooling system operating in accordance with FIG. 3. The supersonic cooling system 300 does not need to compress a gas as otherwise occurs at compressor 110 in a prior art vapor compression system 100 like that shown in FIG. 1. Supersonic cooling system 300 operates by pumping liquid. Because supersonic cooling system 300 pumps liquid, the compression system 300 does not require the use of a condenser 120 as does the prior art compression system 100 of FIG. 1. Supersonic cooling system 300 instead utilizes a compression wave. An evaporator of the supersonic cooling system 300 operates in the critical flow regime where the pressure in an evaporator tube or nozzle will remain almost constant and then ‘jump’ or ‘shock up’ to the ambient pressure.

[0022]The supersonic cooling system 300 of FIG. 3 recogn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com