Cascading Plant

a technology of cascading plants and evaporators, which is applied in the field of refrigeration and air conditioning systems, can solve the problems of high collective damage caused by leveraging emissions, inability to reduce leakage, and rapid degradation of lubricating oil, and achieves reduced mass flow rate, reduced compressor size, and reduced leakage. effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

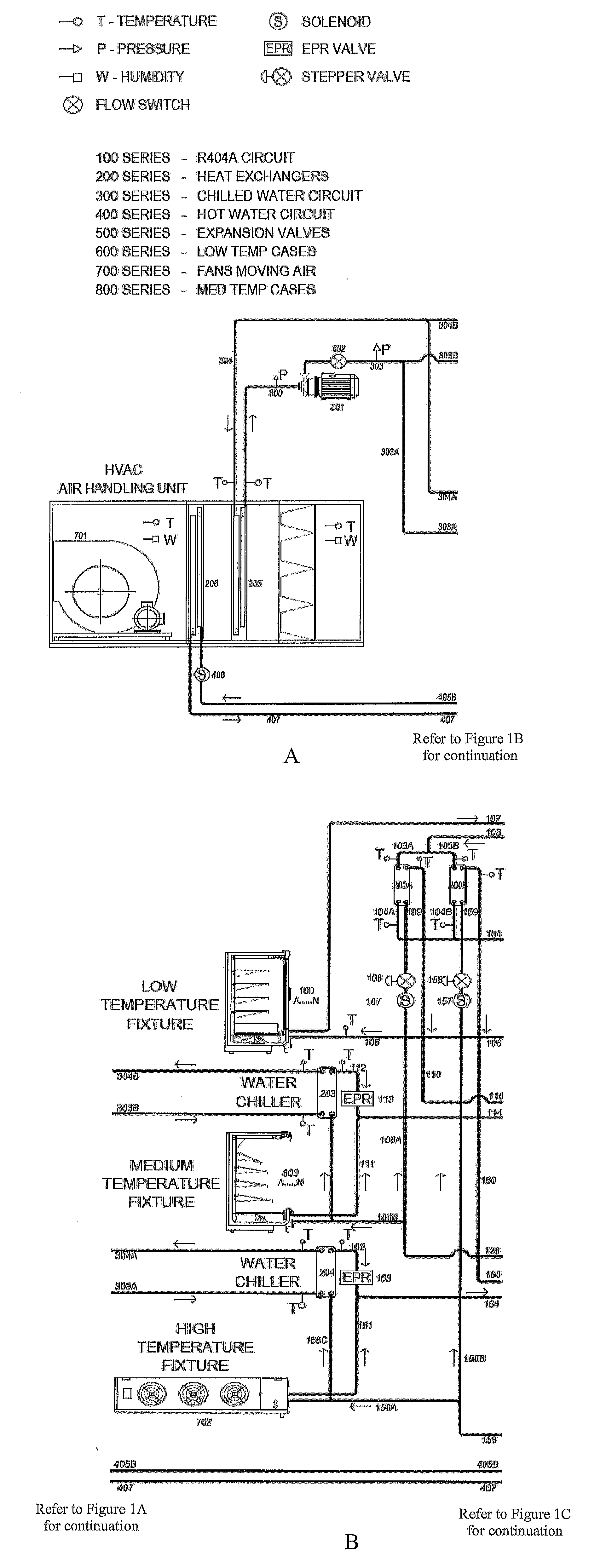

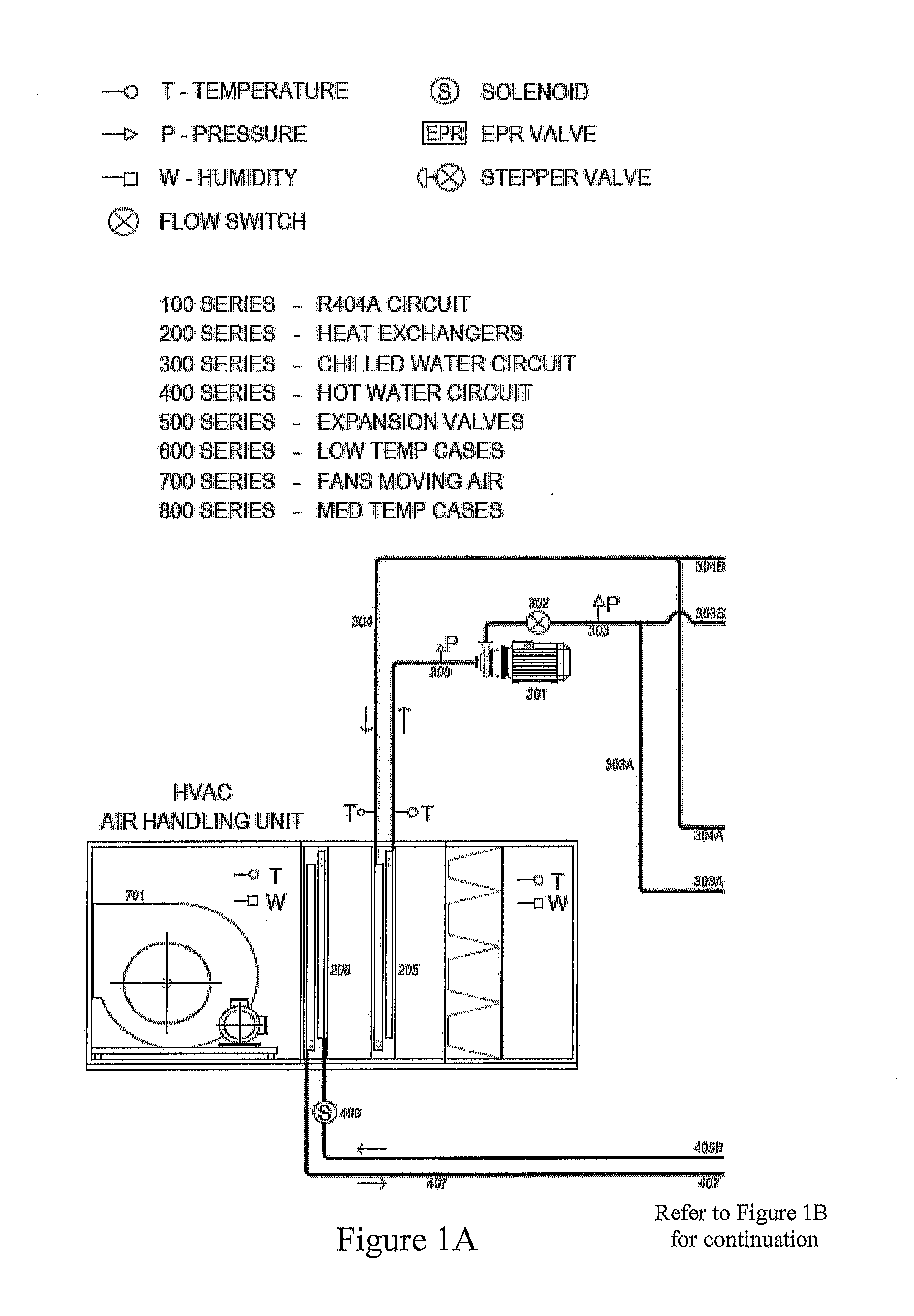

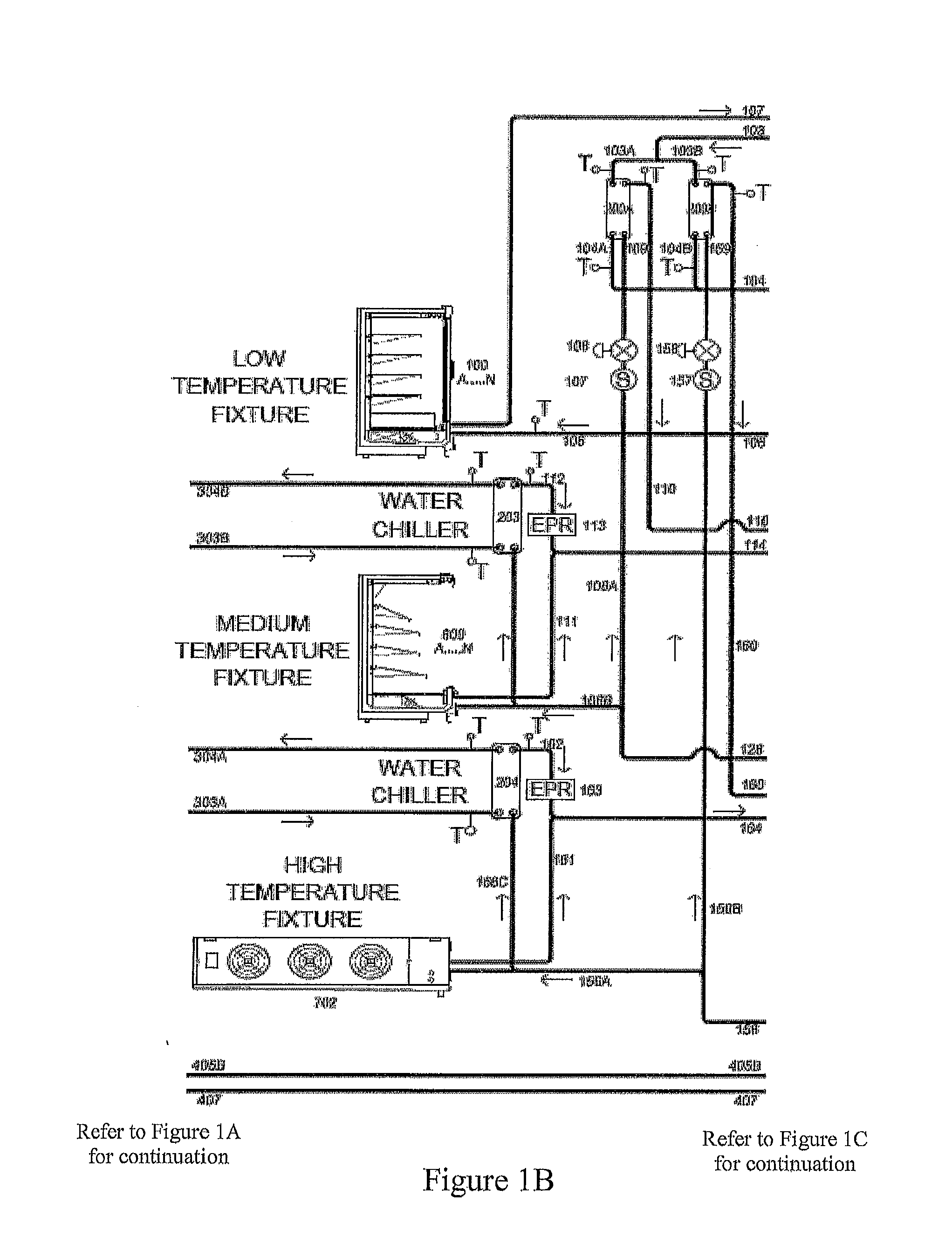

[0038]The invention will now be further illustrated with reference to the non limiting example depicted in the accompanying FIGURE. In this respect the following possibilities exist, all of which are of the inventions disclosed here.

[0039]1. The low and high stage of cascade refrigeration units are used with the same refrigerant 404a or 507a and combine the air conditioning service with the high stage.

[0040]This embodiment eliminates the condenser for the low temperature refrigeration rack. It addressed the concerns of some users who do not want to have two synthetic working fluids on site.

[0041]2. The high stage refrigerant in case 1 above is replaced with a low global warming potential and lower vapour pressure refrigerant such as HFC 134a. This option reduces the direct global warming potential even below that of the option 1 above. The high global warming potential refrigerant is contained within the low stage circuit which caters to much smaller load than the high stage segment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com