Juicer screw structure with material scrapers

A juice extractor and scraper technology, applied in the field of juice extractors, can solve problems such as clogging of slag, malfunction of the extractor, and shortening the service life of juice extracting parts, so as to prolong the service life, low implementation cost, and simple manufacturing process reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

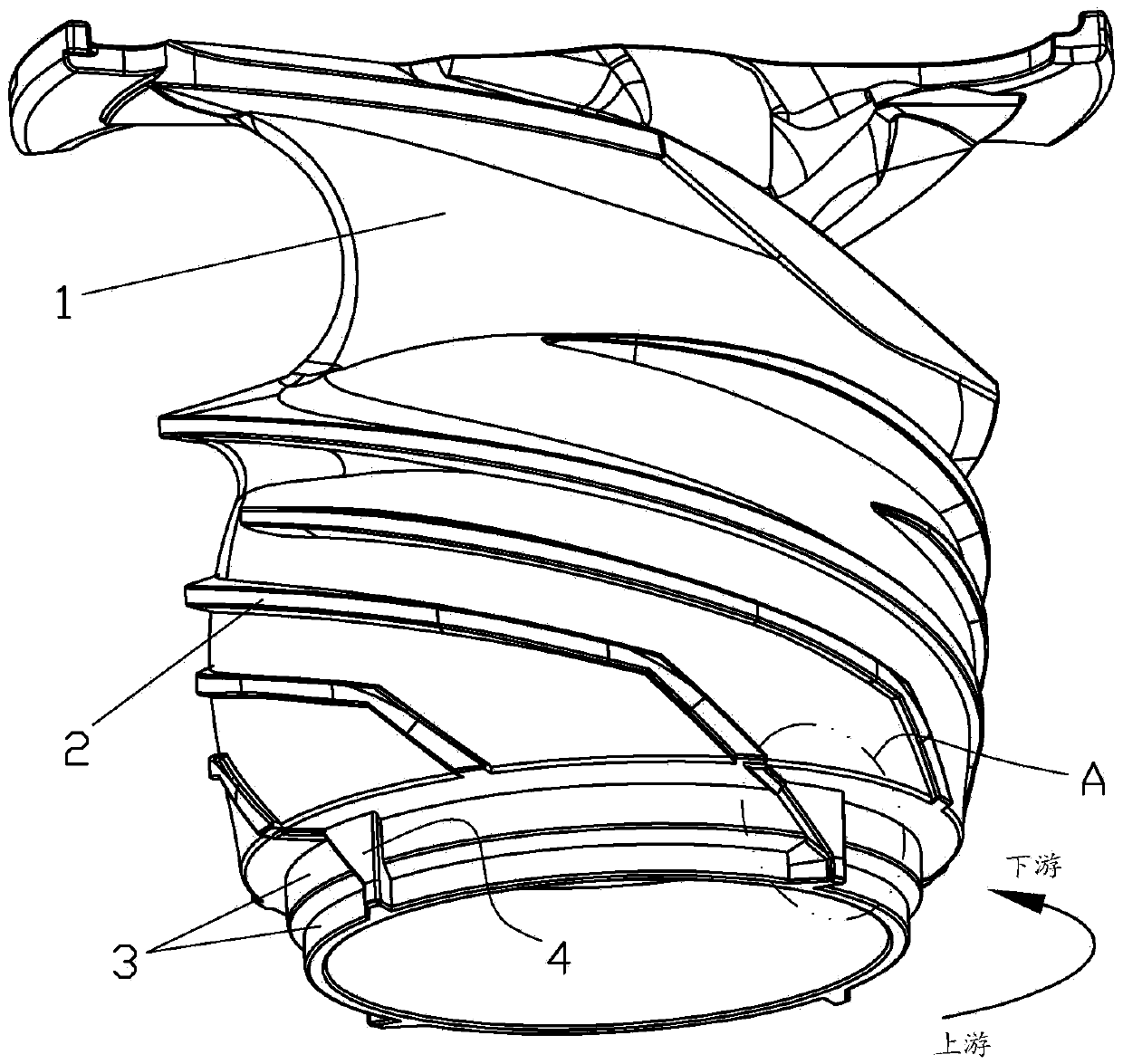

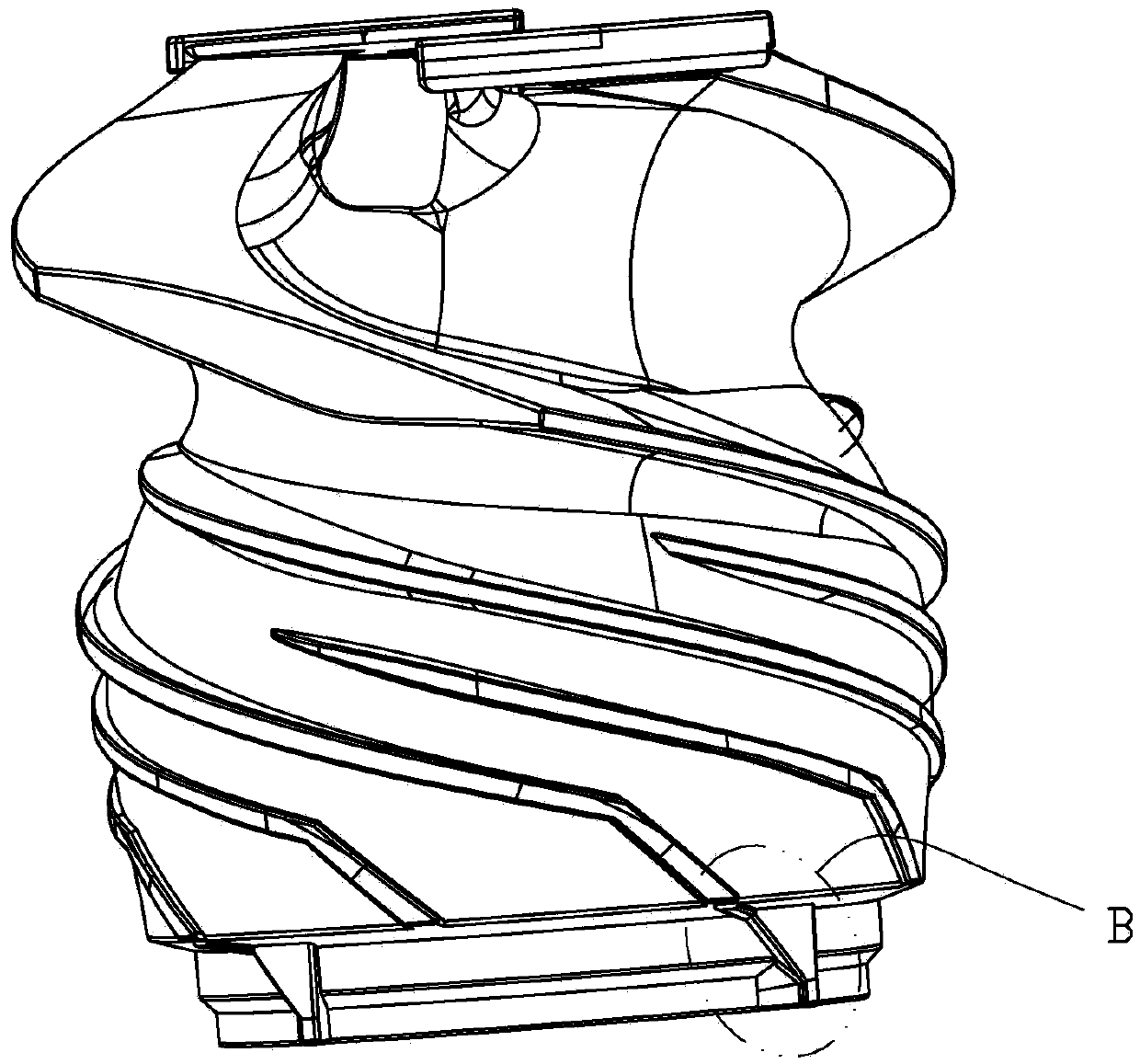

[0020] refer to Figure 1~Figure 4 , a screw structure of a juice extractor with a material scraper of the present invention, comprising a rod body 1, on which the rod body 1 is provided with a thread 2, and the screw thread 2 spirally extends downward from the top of the rod body 1, and on the rod body 1 There is a skirt 3 at the bottom of the screw thread 2, and a scraper 4 is arranged on the skirt 3, and the scraper 4 is used for pushing and scraping fruit and vegetable residues.

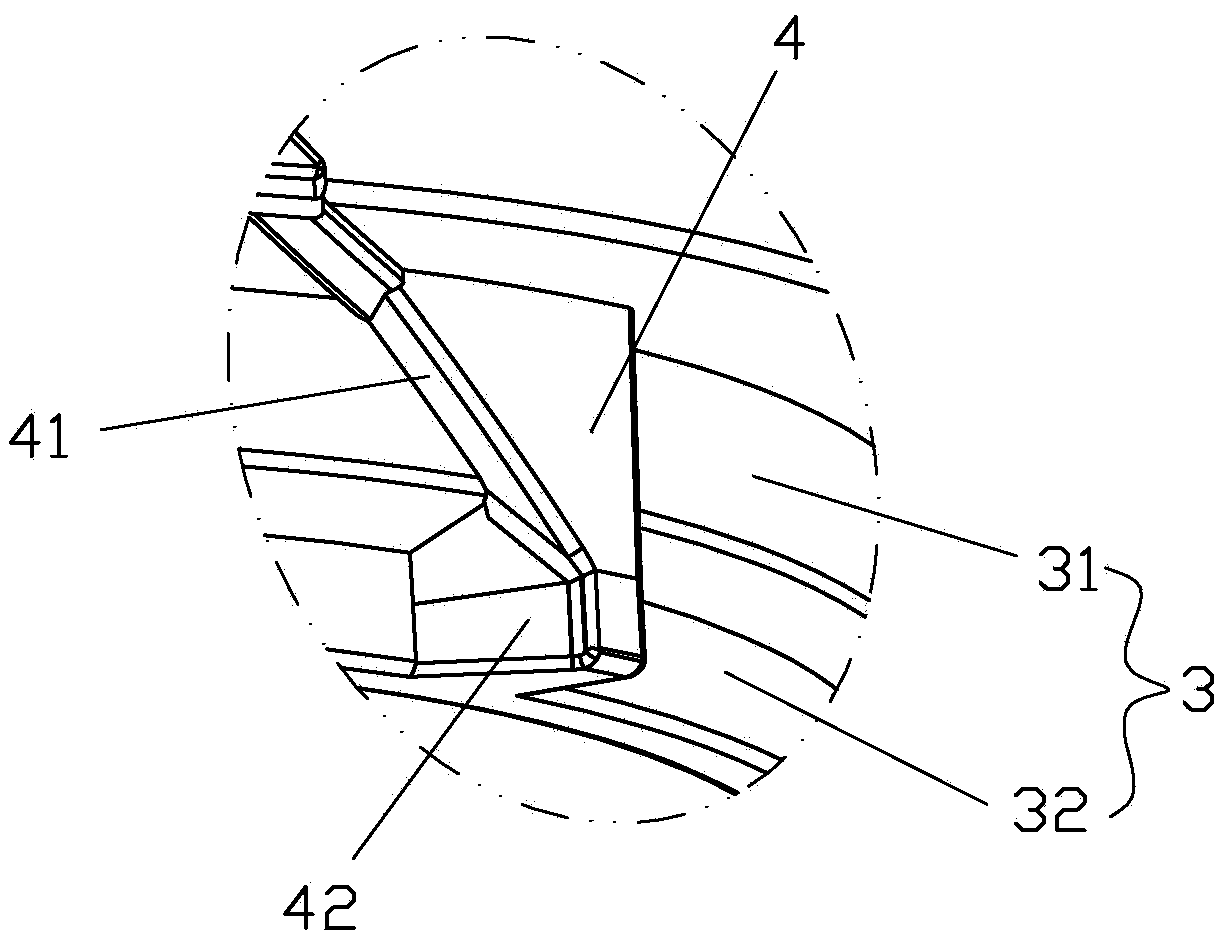

[0021] In this embodiment, preferably, the scraper 4 has a first inclined surface 41 on the downstream side of the screw rotation direction (shown by the arrow in the figure), and the first inclined surface 41 rotates closer to the screw as it goes downward. The direction is inclined to the upstream side, and the first inclined surface 41 acts as a guide. Follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com