Platinum Oxide Colloidal Solution, Manufacturing Method Therefor, Manufacture Apparatus Thereof, and Method of Injection Noble Metal of Boiling Water Nuclear Power Plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

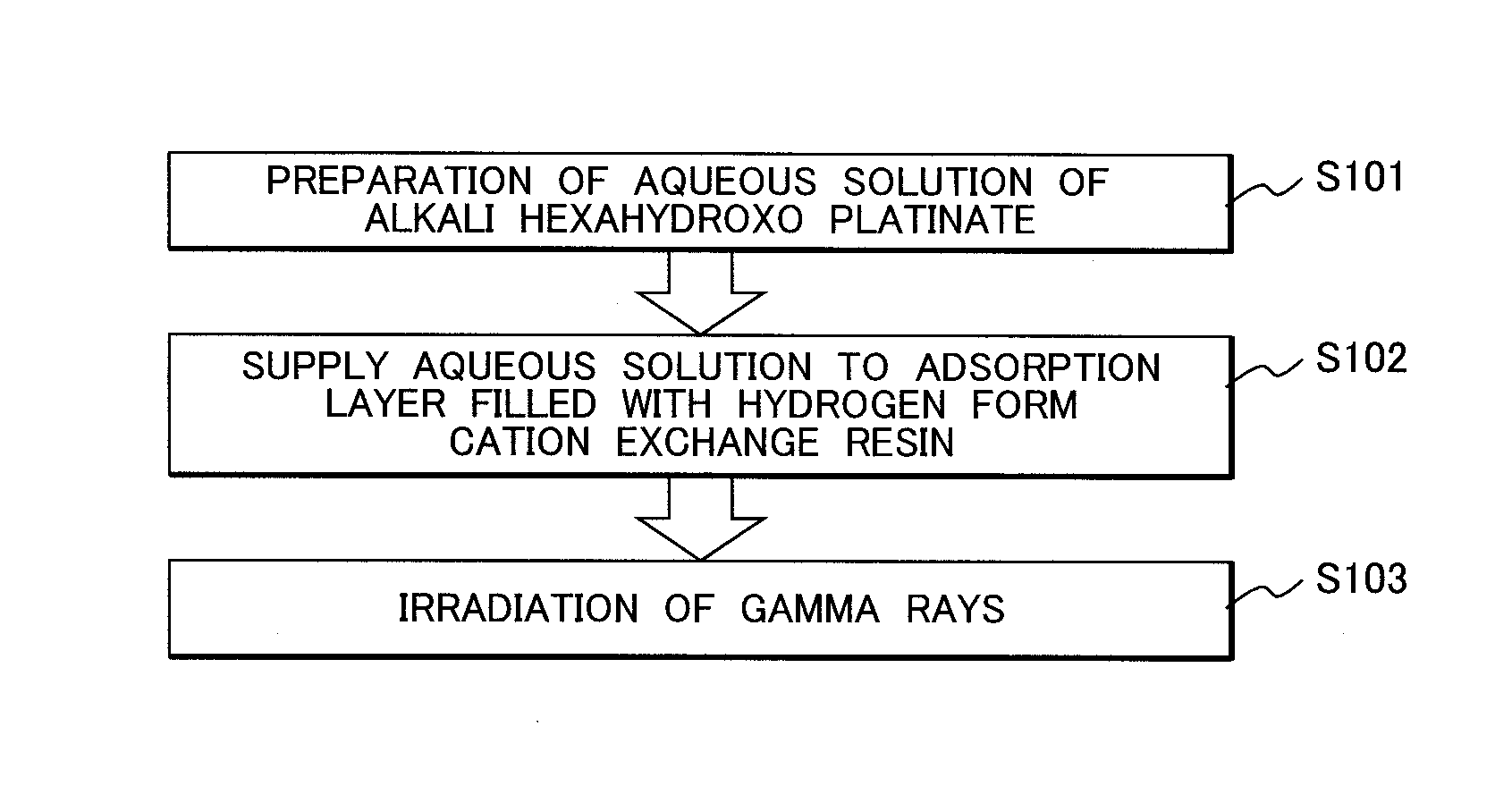

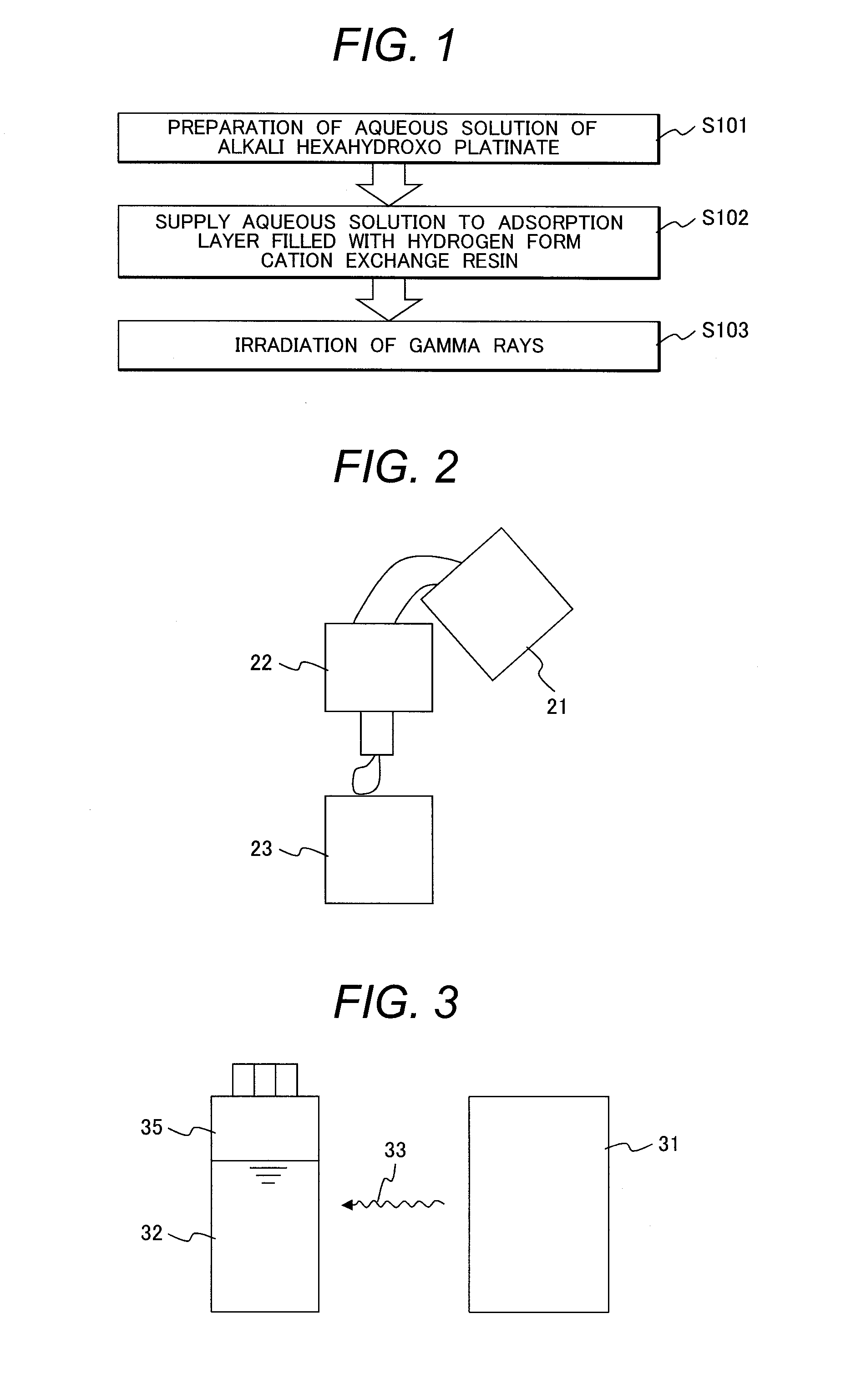

[0053]A method of manufacturing platinum oxide colloidal solution according to embodiment 1 which is a preferable embodiment of the present invention will be explained by referring to FIGS. 1, 2, and 3.

[0054]FIG. 1 shows manufacturing processes of the platinum oxide colloidal solution.

[0055]The manufacturing processes of the platinum oxide colloidal solution include three processes.

[0056]An aqueous solution of a alkali hexahydroxo platinate (hexahydroxoplatinate salt) at a predetermined concentration is produced (step S101). The metallic ions (cations such as sodium ions and potassium ions are removed from the aqueous solution (step S102) (an ion exchange process). Gamma rays are irradiated to the suspension generated due to removal of the metallic ions (step S103) (a colloidal generation process).

[0057]In step S101, the aqueous solution of the alkali hexahydroxo platinate is produced. When the alkali hexahydroxo platinate is obtained as a solid, the solid is dissolved in pure water...

embodiment 2

[0087]The manufacturing method of the platinum oxide colloidal solution according to 2 which is another preferable embodiment of the present invention will be explained by referring to FIG. 8. In the manufacturing method of the present embodiment, the platinum oxide colloidal solution can be manufactured continuously.

[0088]FIG. 8 shows a structure of a manufacturing apparatus of the platinum oxide colloidal solution used for the manufacturing method of the platinum oxide colloidal solution of the present embodiment and the manufacturing apparatus can manufacture continuously the platinum oxide colloidal solution.

[0089]A platinum oxide colloidal solution manufacturing apparatus 60 for manufacturing the platinum oxide colloidal solution is provided with a vessel 61 for storing the aqueous solution of the alkali hexahydroxo platinate, a hydrogen form cation exchange resin tower (cation exchange resin tower) 63 filled with the hydrogen form cation exchange resin, a reaction vessel 64, a...

embodiment 3

[0095]The inventors examined noble metal adsorption phenomenon to suppress the adsorption of the noble metal on the inner surface of the injection pipe. As a result, the following is found. An inner surface of an injection pipe of a noble metal injection apparatus connected to a pipe (for example, a water feed pipe, and a reactor purification system pipe, etc.) connected to a reactor pressure vessel is covered with an iron oxide while solution including noble metal is injected into the pipe connected to the reactor pressure vessel through the injection pipe. As a result, the inner surface of the injection pipe is charged negatively when it makes contact with neutral pure water (pH 7). When a neutral aqueous solution with a noble metal dissolved flows through the injection pipe, cations (for example, Pt4+) of the noble metal in the aqueous solution are electrostatically adsorbed to the negatively charged inner surface of the injection pipe.

[0096]Material is charged positively when it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by atom | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

| Irradiation dose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com