Tunnel inclined shaft construction system and construction method

An inclined shaft and tunnel technology, which is applied to the tunnel inclined shaft construction system and the construction field, can solve the problems of low construction efficiency, large construction investment, difficult conversion of inclined shafts and flat holes, etc., so as to improve the driving efficiency, reduce equipment investment, improve The effect of origination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

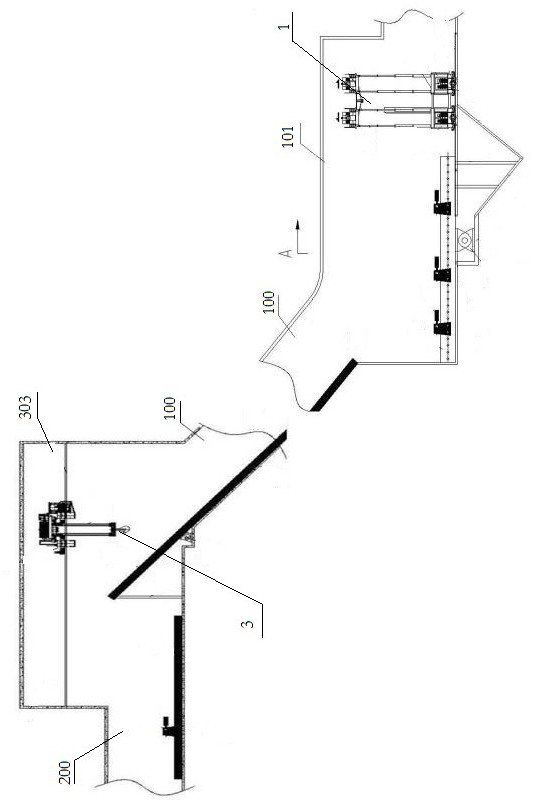

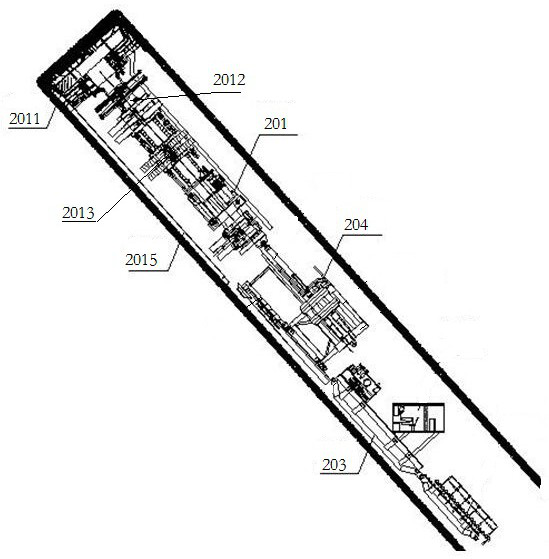

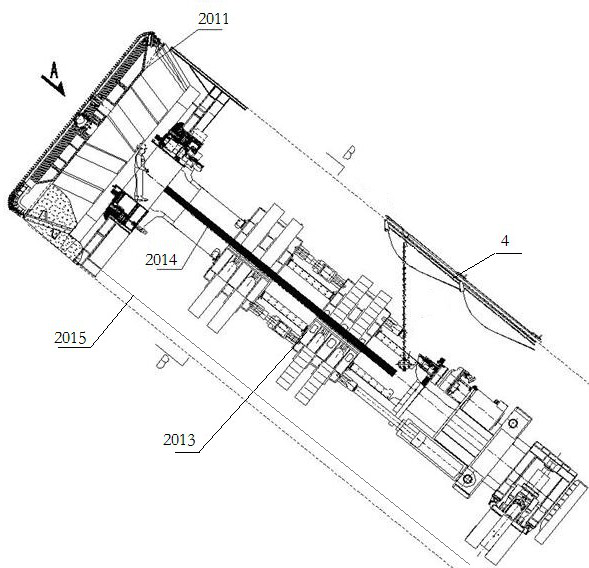

[0063] Embodiment 6: A construction method of a tunnel inclined shaft construction system, the steps are as follows: including the starting device 1, the inclined shaft TBM2 and the receiving device 3, and the inclined shaft excavated by the inclined shaft TBM2 is provided with a follow-up transport system 4; The inclined shaft TBM2 includes a driving main engine 201 and a rear supporting device 203, and a safety anti-slip device 204 is arranged between the driving main engine 201 and the rear supporting device 203;

[0064] S1: Pre-excavate the starting cavern of the starting device 1 and the conversion cavern 303 of the receiving device 3 at a specific location, and install corresponding tooling equipment;

[0065] S2: if Figure 14 As shown, after the launching device 1 of the inclined shaft TBM2 is assembled, the stepping launching platform device 103 of the launching device 1 and the jacking device 102 cooperate to complete the launching of the inclined shaft TBM2 from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com