Optical film

a technology of optical film and film layer, applied in the field of optical film, can solve the problems of difficult thinning, thick and dark apparatus and achieve the desired wavelength dispersion characteristic, excellent melt processability, and low photoelastic constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Production of Copolycarbonate

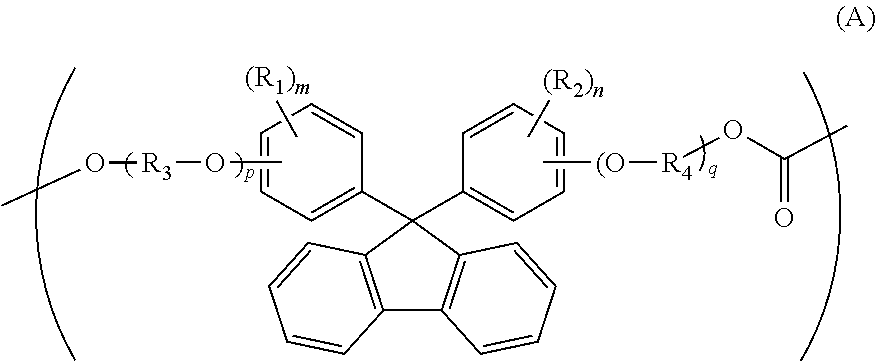

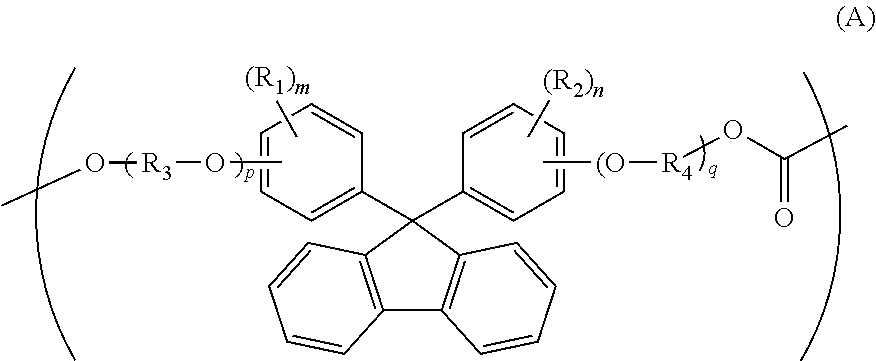

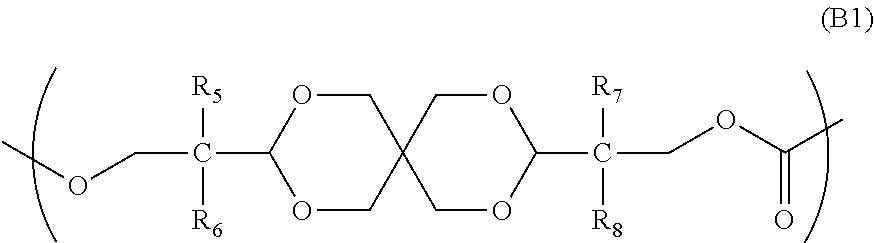

[0126]80.26 parts of 3,9-bis(2-hydroxy-1,1-dimethylethyl)-2,4,8,10-tetraoxaspiro[5.5]undecane (to be referred to as “spiroglycol” hereinafter), 51.41 parts of 9,9-bis(4-hydroxy-3-methylphenyl)fluorene (to be referred to as “BCF” hereinafter), 89.29 parts of diphenyl carbonate, and 1.8×10−2 part of tetramethylammonium hydroxide and 1.6×10−4 part of sodium hydroxide as catalysts were heated at 180° C. in a nitrogen atmosphere to be molten. Thereafter, the degree of vacuum was set to 13.4 kPa over 30 minutes. Then, the temperature was raised to 260° C. at a rate of 60° C. / hr and maintained at that temperature for 10 minutes, and the degree of vacuum was set to 133 Pa or less over 1 hour. A reaction was carried out under agitation for a total of 6 hours. After the end of the reaction, tetrabutylphosphonium dodecylbenzenesulfonate was added in an amount that was 4 times the total molar amount of the catalysts to deactivate the catalysts, and the resulting pro...

example 2

Production of Optical Film

[0129]A film was produced in the same manner as in Example 1. The operation of Example 1 was repeated except that the obtained film was stretched to 2.5 times in the transverse direction to obtain a biaxially oriented film. The thickness, retardation, wavelength dispersion and Nz coefficient of this stretched film were measured. The results are shown in Table 1.

[0130]When the display screen of a liquid crystal panel which was produced by using the obtained stretched film in the same manner as in Example 1 was checked, it had good contrast and a wide view angle.

example 3

[0131]

[0132]The operation of Example 1 was repeated except that 85.13 parts of spiroglycol, 45.37 parts of BCF and 89.29 parts of diphenyl carbonate were used to obtain an aromatic-aliphatic copolycarbonate. The viscosity average molecular weight and glass transition temperature of the obtained pellet were measured, and the composition ratio of the pellet was measured by NMR. The results are shown in Table 1.

[0133]This copolymer was dissolved in methylene chloride to produce a dope having a solid content of 19 wt %. A cast film was produced from this dope solution by a known method. The operation of Example 1 was repeated to obtain a biaxially oriented film from this film. The thickness, retardation, wavelength dispersion and Nz coefficient of this stretched film were measured. The results are shown in Table 1.

[0134]When the display screen of a liquid crystal panel which was produced from the obtained stretched film in the same manner as in Example 1 was checked, it had good contras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com