Alkali free glass

A technology of non-alkali glass and photoelastic constant, which is applied in the field of non-alkali glass, can solve the problems such as the deterioration of film properties, and achieve the effect of not easy to color unevenness, high strain point, and not easy to bend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

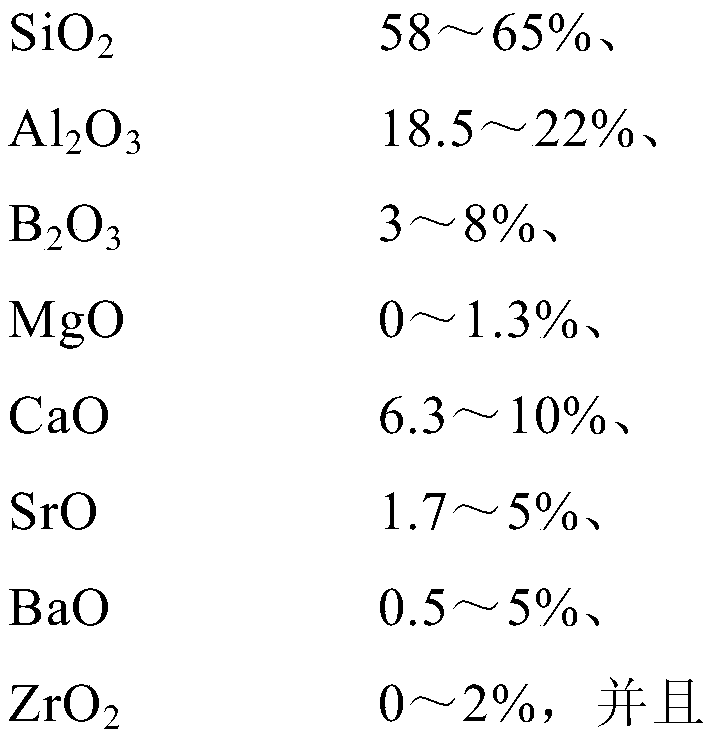

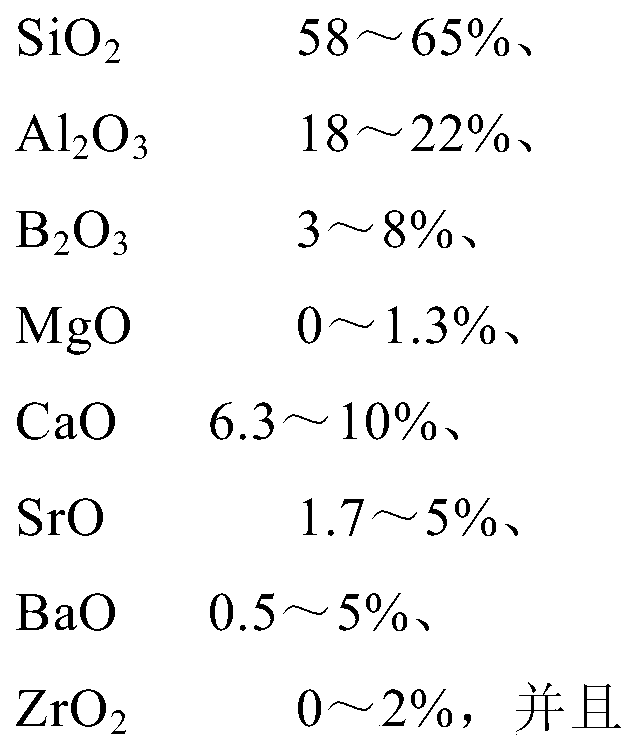

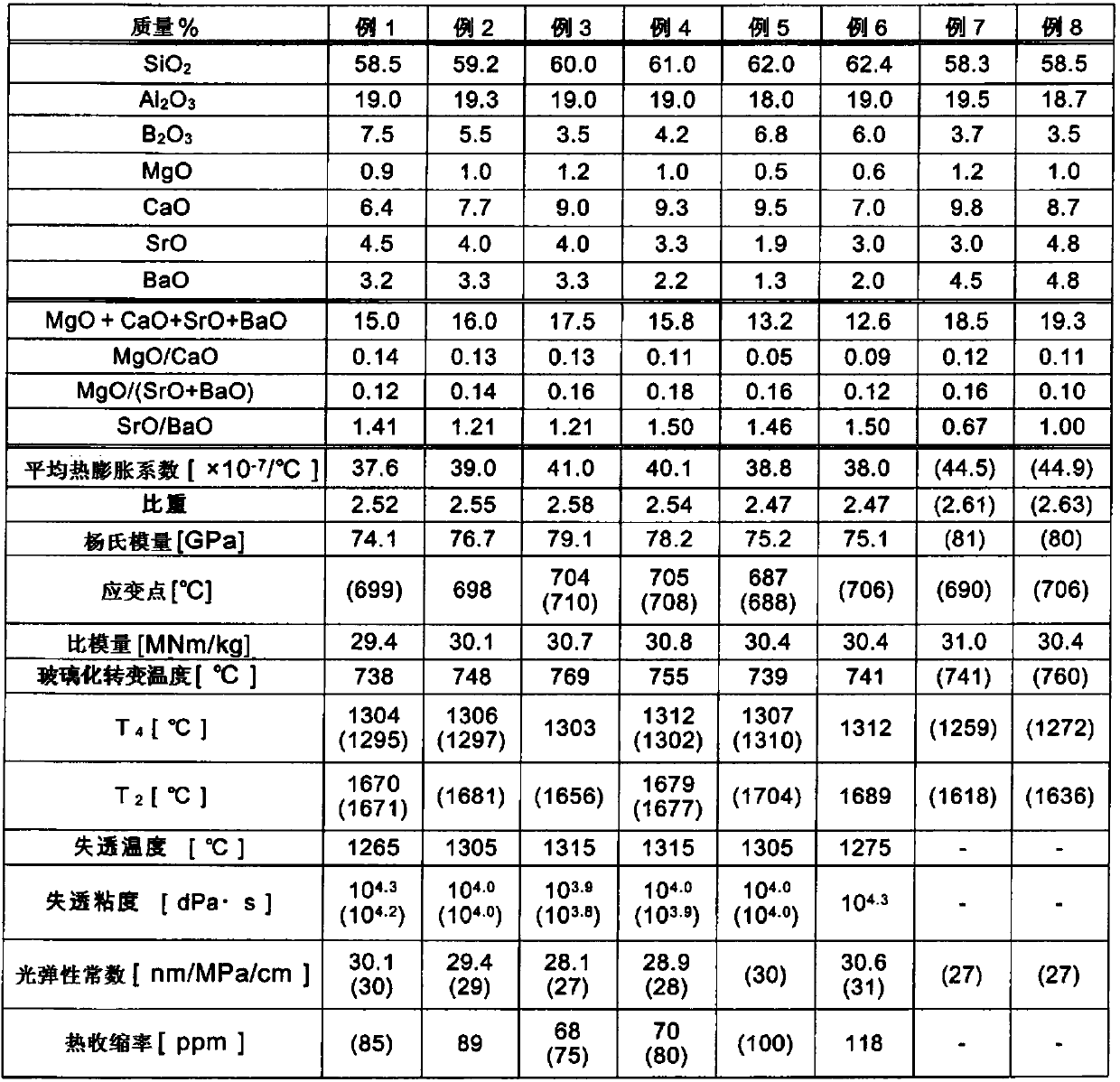

[0077] (Examples: Examples 1-6 and Examples 9-15, Comparative Examples: Examples 7-8)

[0078] Hereinafter, although an Example and a comparative example demonstrate this invention in detail, this invention is not limited to these Examples.

[0079] Raw materials of each component were prepared so that the glass composition became the target composition shown in Table 1 and Table 2 (glass composition (unit: mass %)), and melted at a temperature of 1600° C. for 1 hour using a platinum crucible. After melting, it was poured onto a carbon plate, held at the glass transition temperature + 30°C for 60 minutes, and then cooled to room temperature at 1°C per minute. The obtained glass was mirror-polished to obtain a glass plate, and various evaluations were performed.

[0080] In Tables 1 and 2, the average coefficient of thermal expansion at 50 to 350°C is shown (unit: ×10 -7 / ℃), specific gravity, Young's modulus (GPa), strain point (unit: ℃), glass transition temperature (unit:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com