Silicate glass substrate for flat-panel display

A silicate glass and flat display technology, which is applied in the field of organic electroluminescent display (OEL) substrate glass and alkaline earth aluminum borosilicate glass components, can solve the problem of low electron mobility, high aperture ratio, and influence on the backlight source. Effective utilization and other issues to achieve the effect of high strain point, production cost reduction, raw material cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

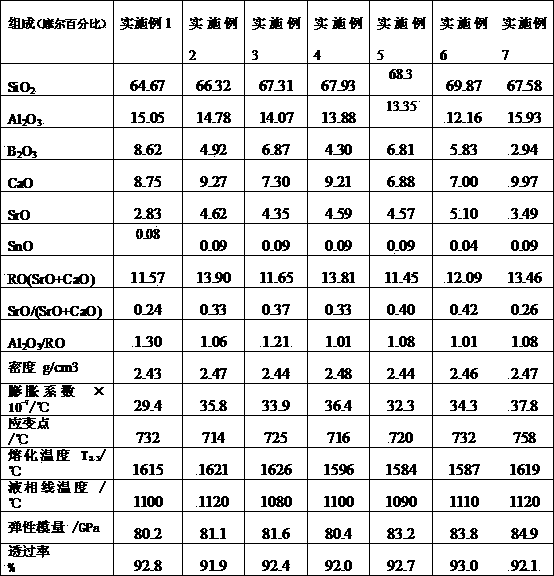

[0022] The silicate glass substrate used for flat panel display, the composition of each chemical component in the raw material is as follows in molar percentage:

[0023] SiO 2 64~70%,

[0024] Al 2 o 3 12~16%,

[0025] B 2 o 3 3~8.5%,

[0026] CaO 6.5~9.5%,

[0027] SrO 2.5~5%,

[0028] SnO 0.02~0.1%.

[0029] In terms of molar percentage, wherein said SrO / (SrO+CaO)2 o 3 / (SrO+CaO)>1.0. It can greatly increase the strain point, and more importantly, reduce the melting temperature of the glass at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com