Glass composition, high-transmittance glass, preparation method of high-transmittance glass, and application of glass composition and high-transmittance glass

A technology with high transmittance and composition, which is applied in the field of glass manufacturing, can solve the problems of low glass transition temperature, high thermal expansion coefficient, and difficulty in ultra-thinning, and achieve low thermal expansion coefficient, good heat resistance, and increased strain point. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-18 and comparative example 1-4

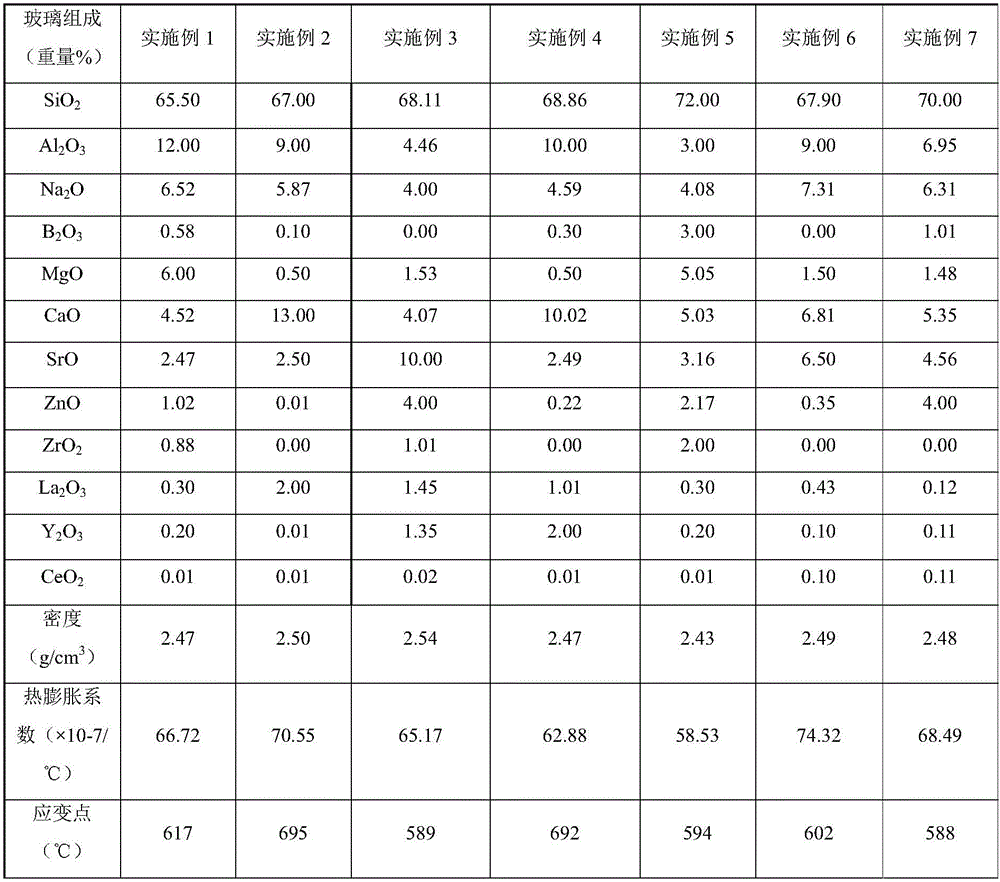

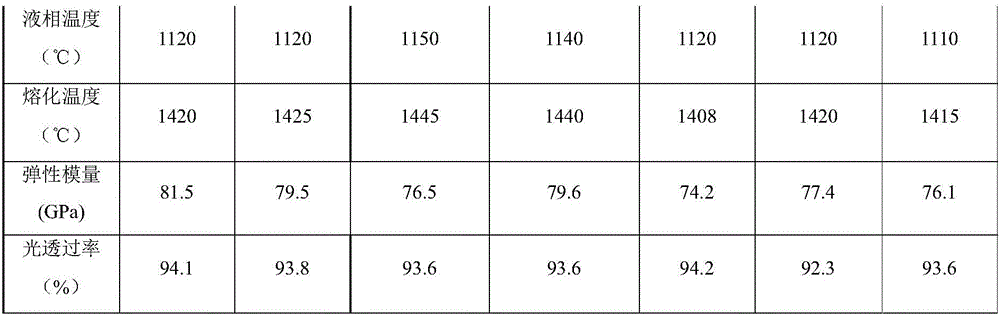

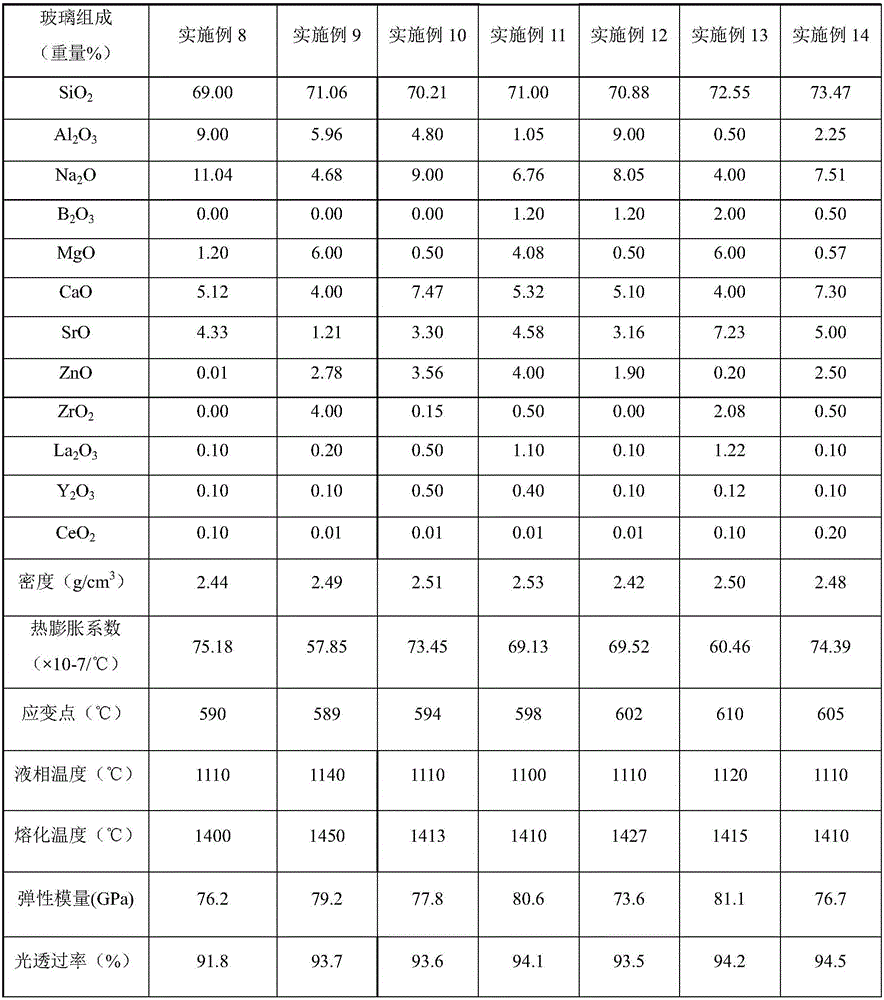

[0059] Weigh the raw materials of each glass composition according to the ratio shown in Table 1-3, mix them uniformly, pour them into a platinum crucible, melt them in a silicon-molybdenum rod high-temperature melting furnace, keep them warm at 1400°C for 10h, and use a platinum rod Stir to remove air bubbles and homogenize the molten glass, then cool the melted glass to the temperature range required for molding, and after annealing, make a glass substrate with the thickness required for the light guide plate, and then simply process the formed glass substrate Finally, the physical properties of the glass substrate are tested, and the test results are shown in Table 1-3 below.

[0060] Table 1

[0061]

[0062]

[0063] Table 2

[0064]

[0065] table 3

[0066]

[0067] As can be seen from the data in Table 1-3, the density of the high transmittance glass prepared by the present invention is less than 2.55g / cm 3 , The coefficient of thermal expansion at 50-35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com