Alkali-free glass substrate and method for reducing thickness of alkali-free glass substrate

A non-alkali glass and substrate technology, applied in the field of non-alkali glass substrates, can solve the problems of large thermal expansion and high density, and achieve the effects of high strain point, high etching speed and not easy to bend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

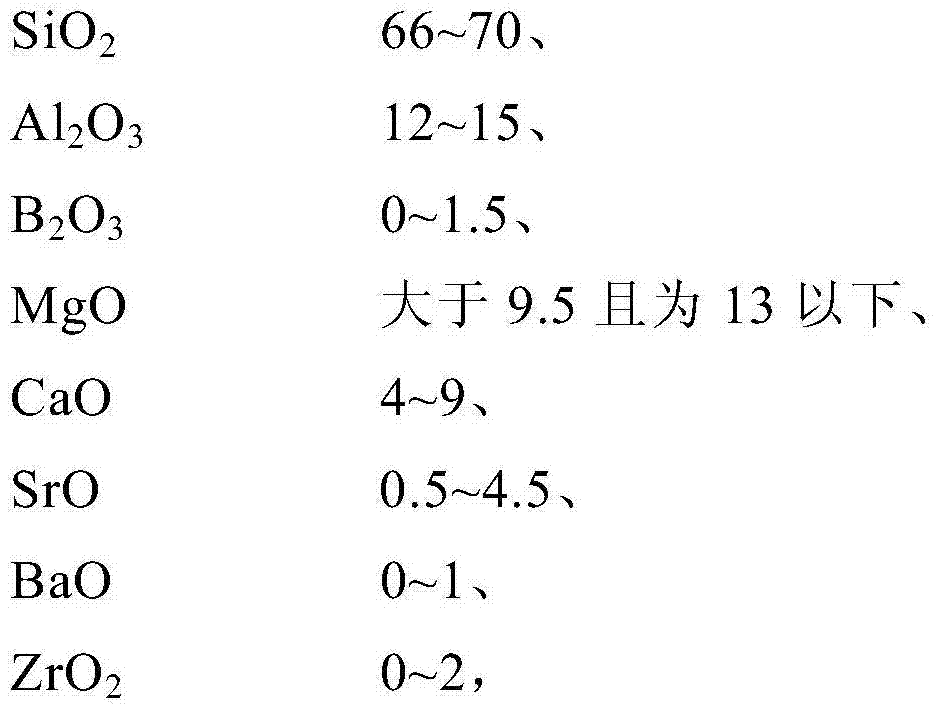

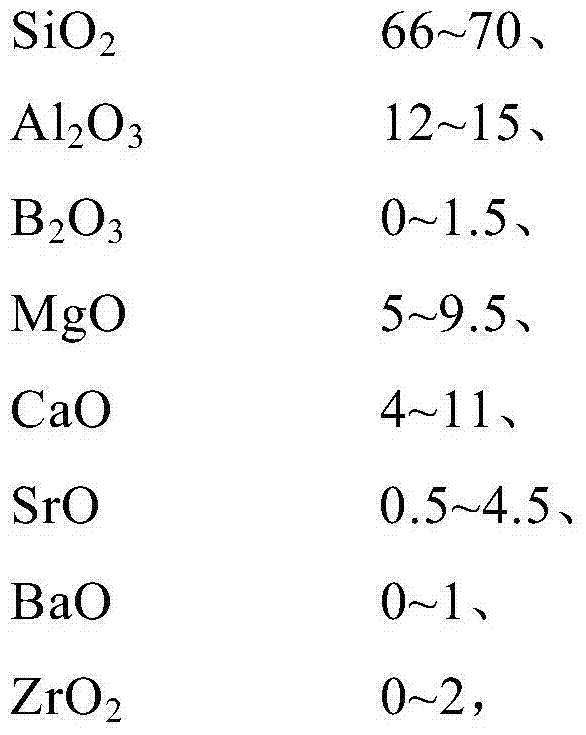

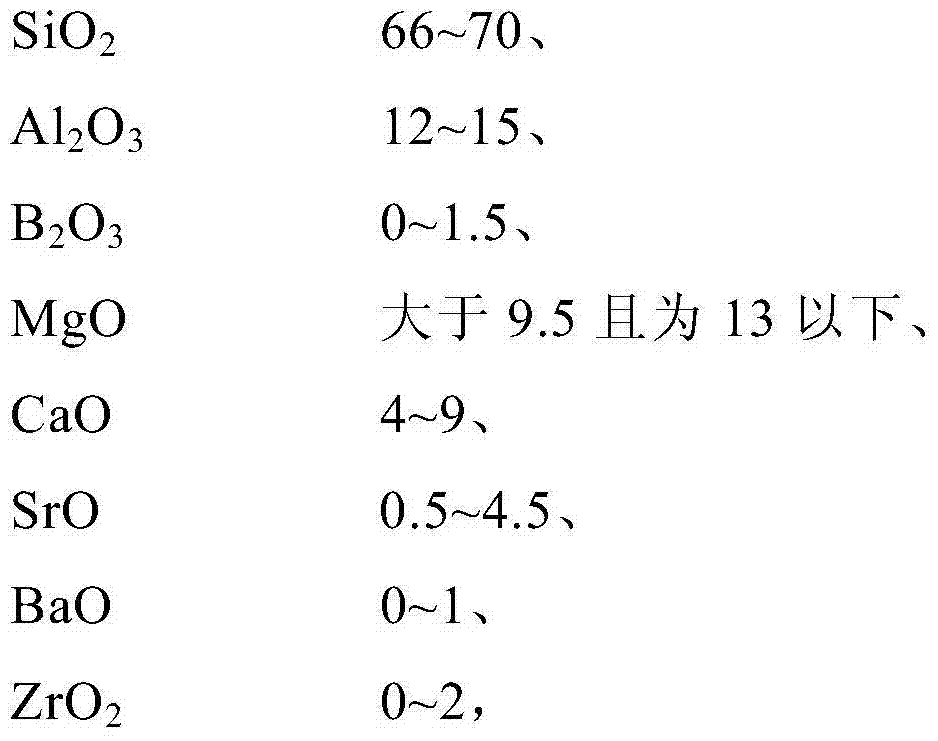

Method used

Image

Examples

Embodiment 1、2

[0155] (Example 1, 2, Comparative Example 1)

[0156] The raw materials of each component were prepared so that the target composition shown in Table 1 was obtained, melted in a continuous melting furnace, and formed into a flat plate by a float method to obtain an alkali-free glass substrate.

[0157] After mirror-polishing the obtained glass substrate, one side of the glass substrate was etched while bubbling with a mixed acid of 8 mass % hydrofluoric acid and 10 mass % hydrochloric acid, so that the thickness of the plate changed from 0.7 mm to 0.7 mm. 0.4mm, so as to reduce the thickness.

[0158] Using the thinned glass substrate, the breaking load was measured five times by the ball-and-ring (BOR) method using a SUS ring with a diameter of 30 mm and R = 2.5 mm and a SUS ball with a diameter of 10 mm. Table 2 shows the average breaking load converted to a plate thickness of 0.4 mm.

[0159] In addition, when the plate thickness was etched to 30 μm by the same procedure ...

Embodiment 3~5、 comparative example 2

[0171] The raw materials of each component were prepared so that the target compositions shown in Examples 3 to 5 in Table 3 were prepared, and melted at a temperature of 1650° C. for 1 hour using a platinum crucible. After melting, it flows out into a carbon plate shape, and after being kept at a temperature of glass transition temperature + 30° C. for 1 hour, it is cooled at 1° C. / minute and annealed to obtain an alkali-free glass substrate.

[0172] After mirror-polishing the obtained glass substrate, one side of the glass substrate was etched while bubbling with a mixed acid of 8 mass % hydrofluoric acid and 10 mass % hydrochloric acid, so that the thickness of the plate changed from 0.7 mm to 0.7 mm. 0.4mm, so as to reduce the thickness.

[0173] Using the thinned glass substrate, the breaking load was measured five times by the ball ring (BOR) method using a SUS ring with a diameter of 30 mm and R = 2.5 mm and a SUS ball with a diameter of 10 mm. Table 4 shows the avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com