Preparation method capable of having hydrophobic characteristic on complex liquid phase and eliminating static accumulation surface

A technology that eliminates static electricity and liquid phase. It is used in devices that coat liquid on surfaces, special surfaces, and pretreated surfaces to achieve the effect of promoting liquid repellency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

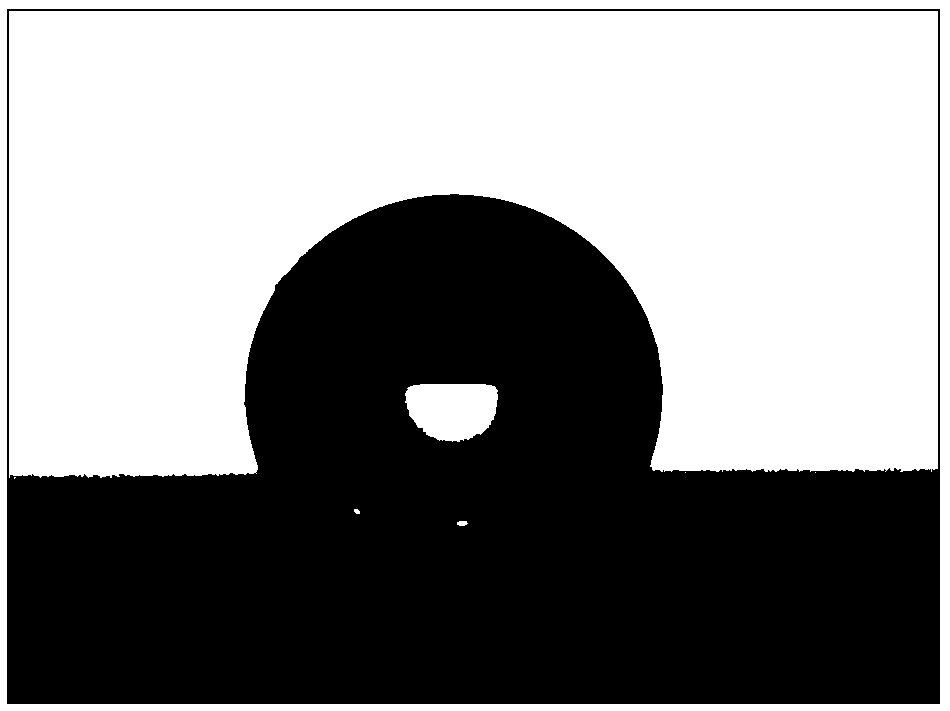

Embodiment 1

[0018] Using a stainless steel sheet as the substrate, use ethanol to ultrasonically clean the substrate for 1 hour to remove grease and other pollutants on the surface of the substrate; use 150nm copper particles as the conductive dispersed phase at a concentration of 20g / L, and heptadecafluorodecanetrimethoxysilane It is a solute with a solubility of 0.1mol / L, and toluene is used as a solvent to configure a spray solution; the configured spray solution is stirred in a mechanical stirring device at 30° for 24 hours; the prepared spray solution is placed in a spray gun, and the spray gun The caliber is adjusted to 50um, and the stainless steel sample is evenly sprayed, and the coating film thickness is controlled to 0.5mm; the sprayed sample is dried in an oven at 80°C for 24h. Glycerol is used as the liquid phase, and aluminum powder particles with a mass fraction of 20% are dispersed in it to form a complex liquid phase of aluminum powder / glycerin. The complex liquid phase is...

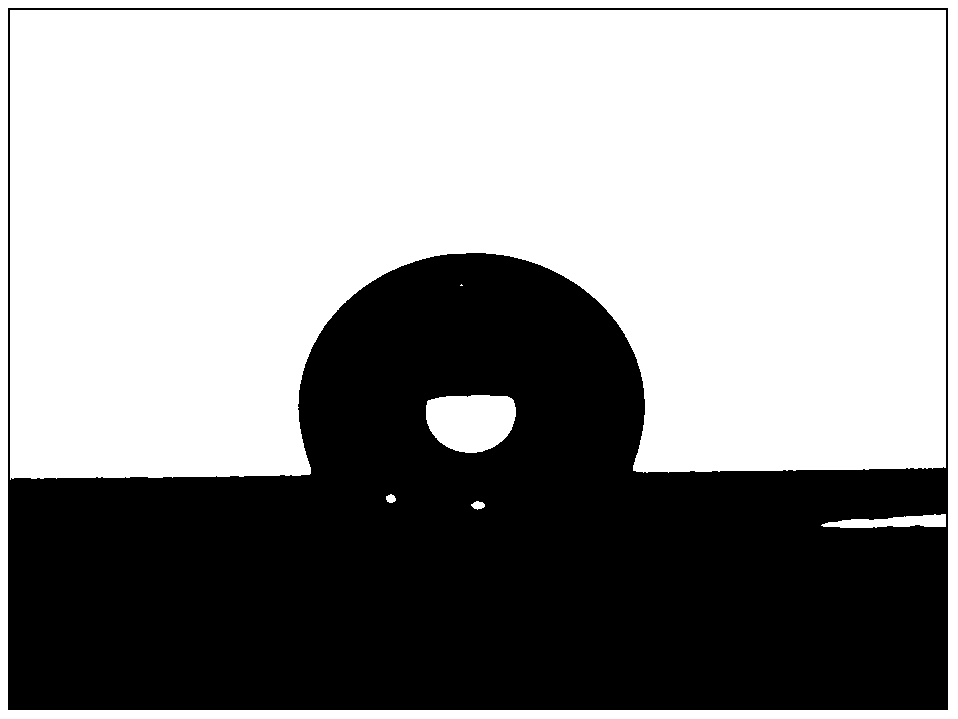

Embodiment 2

[0020] Using glass as the substrate, the substrate was ultrasonically cleaned with ethanol for 1 hour to remove grease and other pollutants on the surface of the substrate; 150nm copper particles were used as the conductive dispersed phase at a concentration of 20g / L, and heptadecafluorodecanetrichlorosilane was used as the Solute, the solubility is 0.5mol / L, using toluene as solvent, configure the spray solution; the configured spray solution is stirred in the mechanical stirring device at 30 ° for 48h; the prepared spray solution is placed in the spray gun, the spray gun caliber Adjust it to 20um, and spray evenly on the glass sample, and control the coating film thickness to 1mm; the sprayed sample is placed in an oven at 80°C for 72 hours. Hydroxyl-terminated polybutadiene (HTPB) is used as the liquid phase, and Fox-7 particles with a mass fraction of 30% are dispersed inside to form a Fox-7 / HTPB complex liquid phase, and the complex liquid phase is dropped on the prepared ...

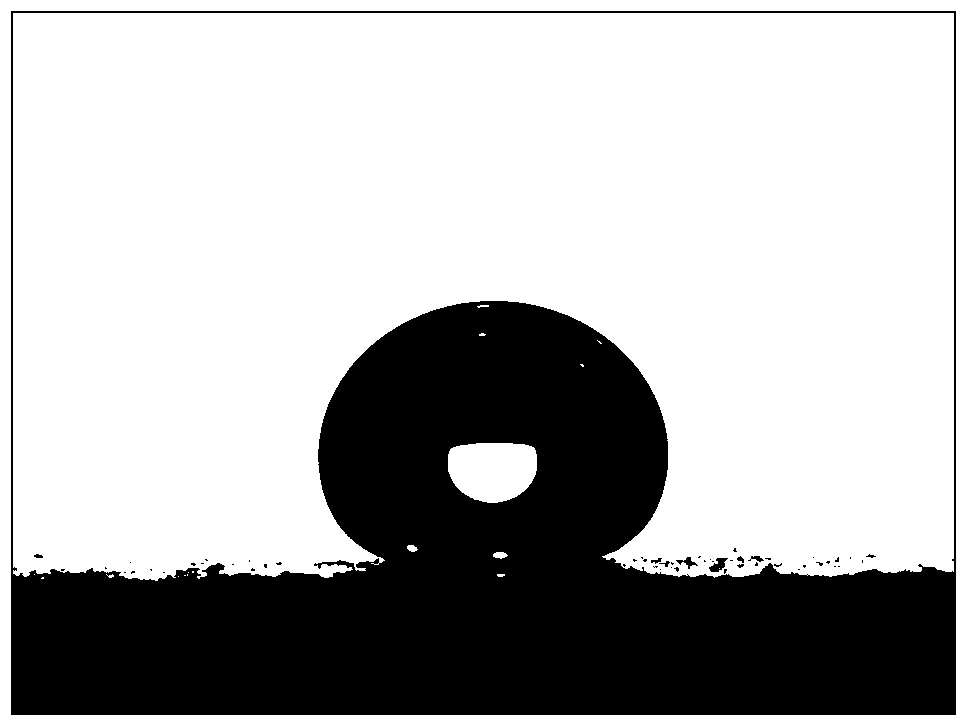

Embodiment 3

[0022] Using silicon wafers as the substrate, the substrate was ultrasonically cleaned with ethanol for 1 hour to remove grease and other pollutants on the surface of the substrate; 50nm gold particles were used as the conductive dispersed phase at a concentration of 2g / L, and heptadecafluorodecanetrichlorosilane was used as the Solute, the solubility is 0.5mol / L, using toluene as solvent, configure the spray solution; the configured spray solution is stirred in the mechanical stirring device at 50 ° for 48h; the prepared spray solution is placed in the spray gun, the spray gun caliber Adjust it to 10um, and spray evenly on the glass sample, and control the coating film thickness to 0.2mm; the sprayed sample is dried in an oven at 80°C for 72h. Hydroxyl-terminated polybutadiene (HTPB) is used as the liquid phase, and Fox-7 particles with a mass fraction of 30% are dispersed inside to form a Fox-7 / HTPB complex liquid phase, and the complex liquid phase is dropped on the prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com