Prefabricated concrete box culvert using grouting method and bidirectional anchoring system as well as mounting structure and method thereof

A technology of prefabricated concrete and box culverts, which is applied in the fields of earthwork drilling, underwater structures, and foundation structure engineering, etc. It can solve problems such as cutting off steel bars, large loss of steel bar materials, and reduced prestress of steel tendons, so as to avoid damage , loss reduction, strong connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is an introduction to a preferred embodiment of the present invention according to the accompanying drawings. In the following introduction of the present invention, in order to briefly introduce the subject matter of the present invention, related known functions and structures will not be described in detail.

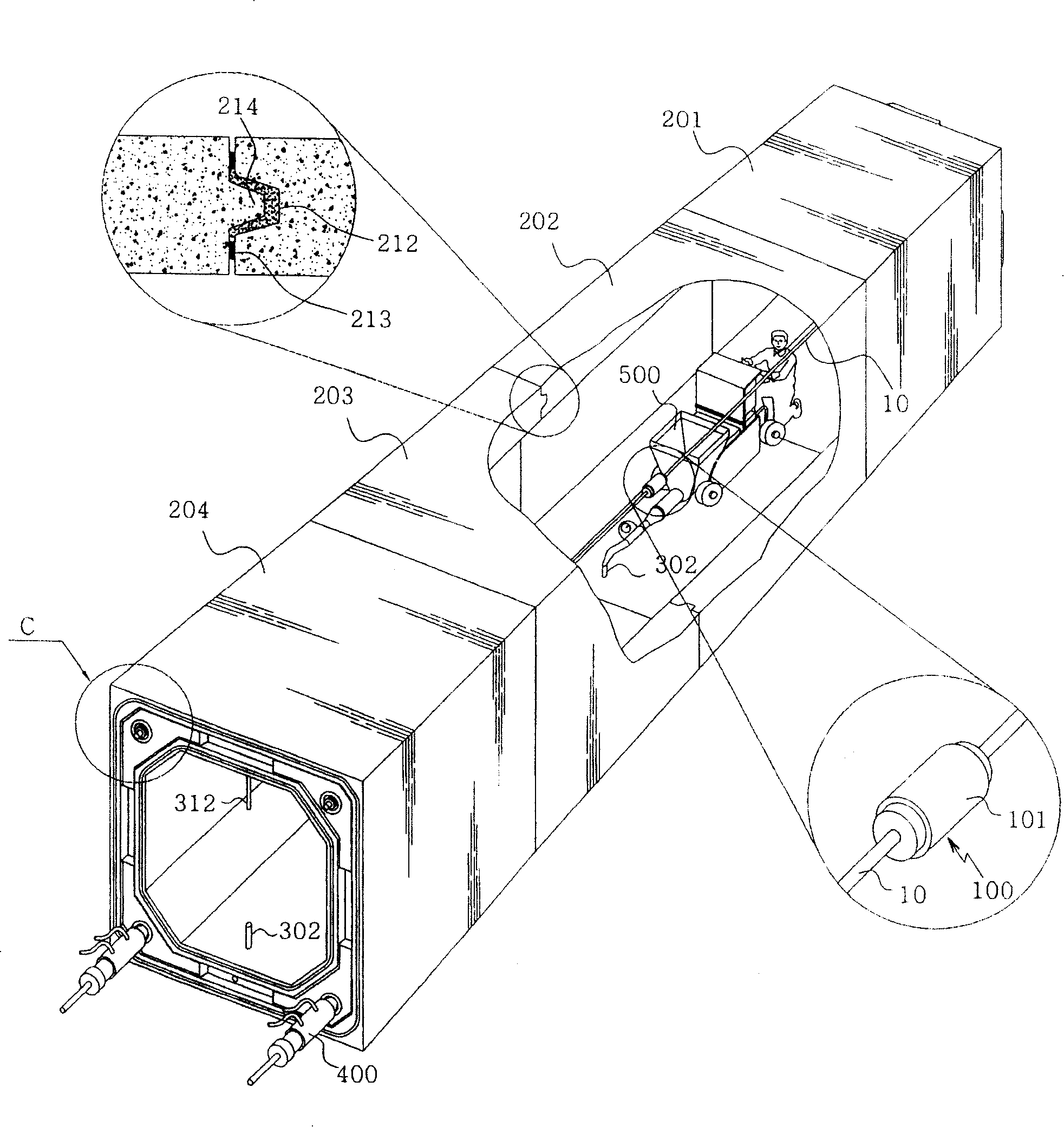

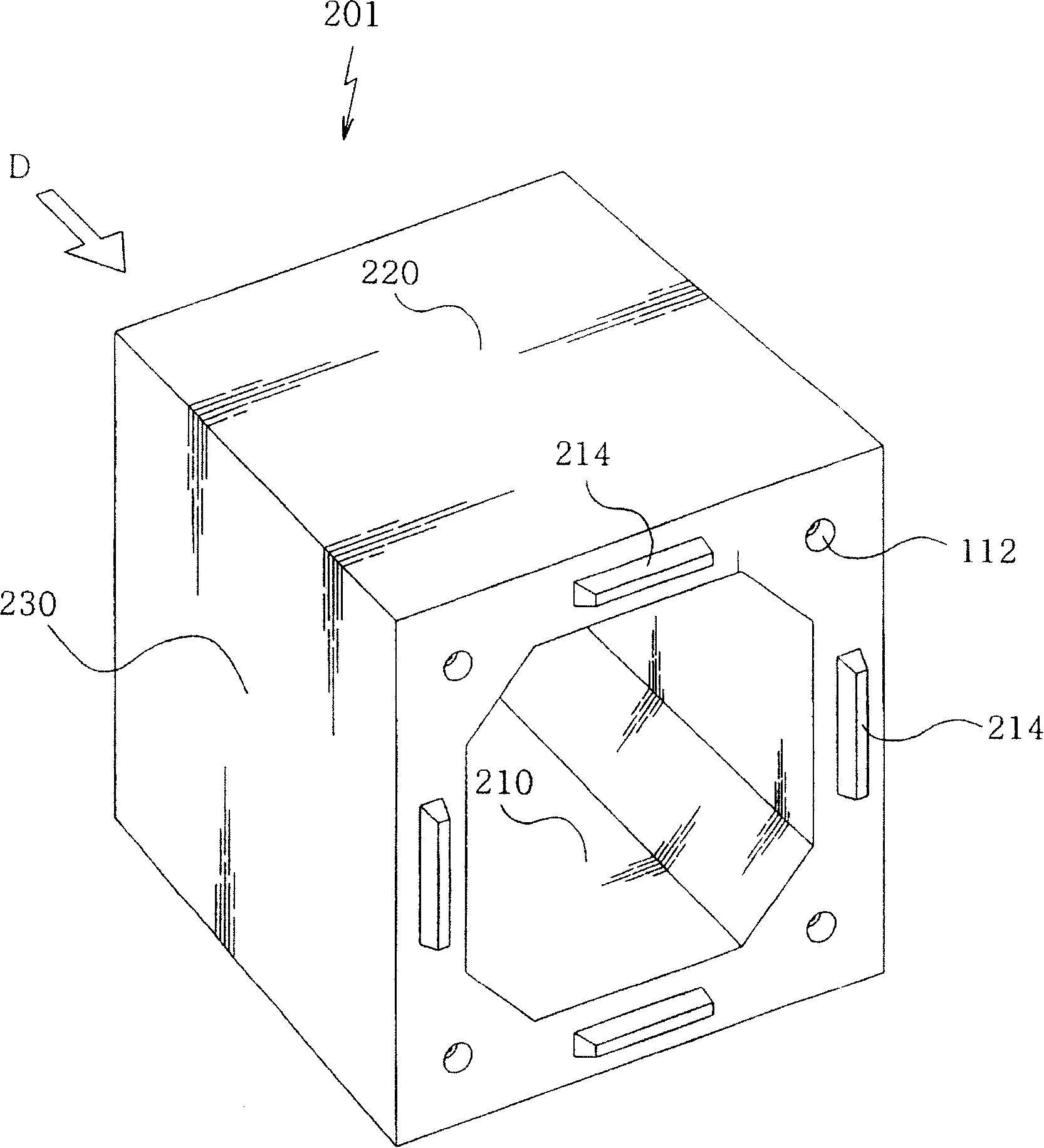

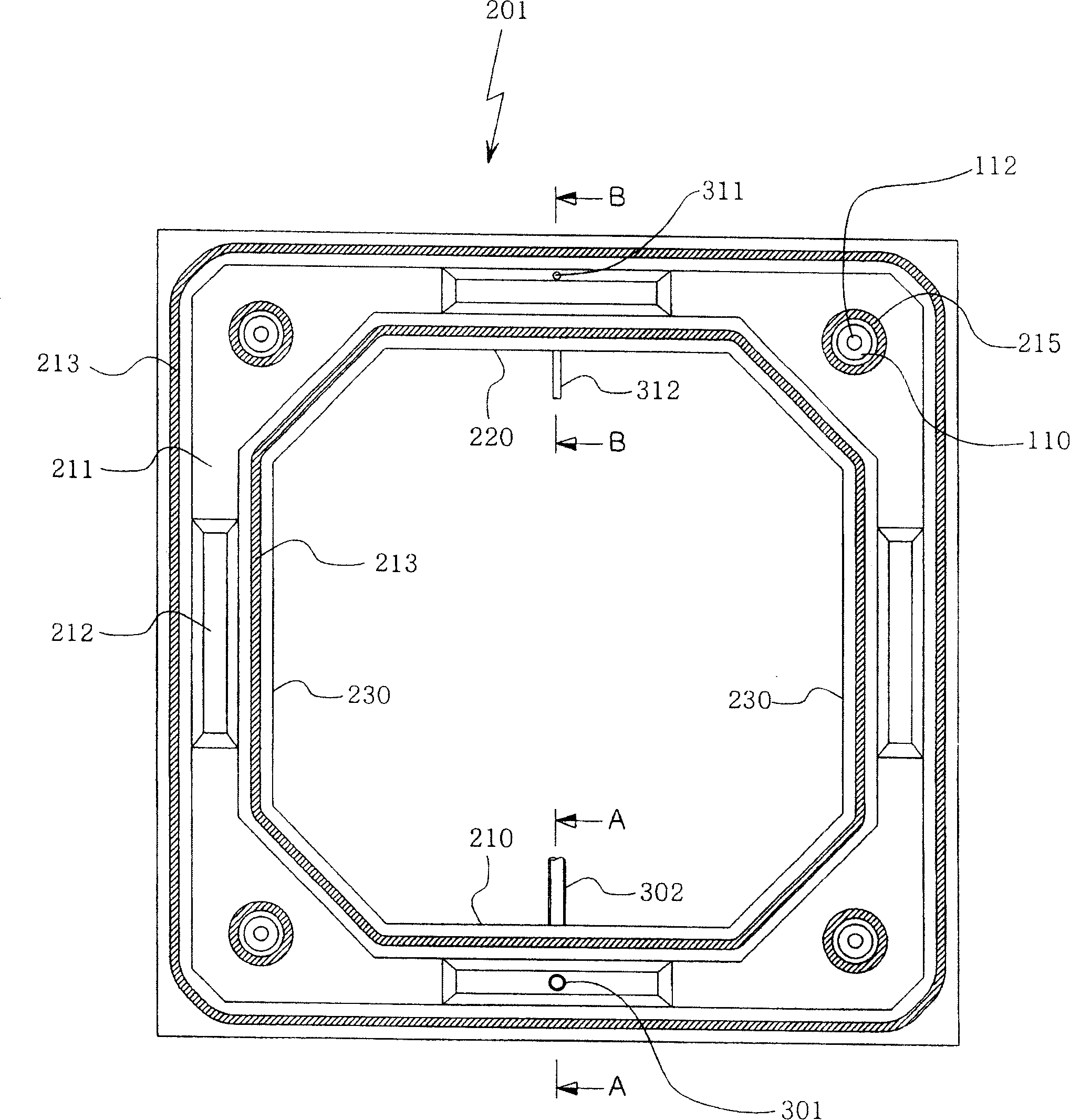

[0024] figure 1 is a perspective view of a precast concrete box culvert assembled according to one embodiment of the invention, figure 2 is a perspective view of a precast concrete box culvert according to an embodiment of the present invention, image 3 yes figure 2 The front view of the precast concrete box culvert seen in the direction of arrow D in .

[0025] As shown in these drawings, a joint surface of the precast concrete box culvert is provided with a mortar recess 211, and when the precast concrete box culverts are connected to each other, a space can be created through which mortar can be filled. The mortar recess 211 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com