Substrate structures applied in flexible electrical devices and fabrication method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

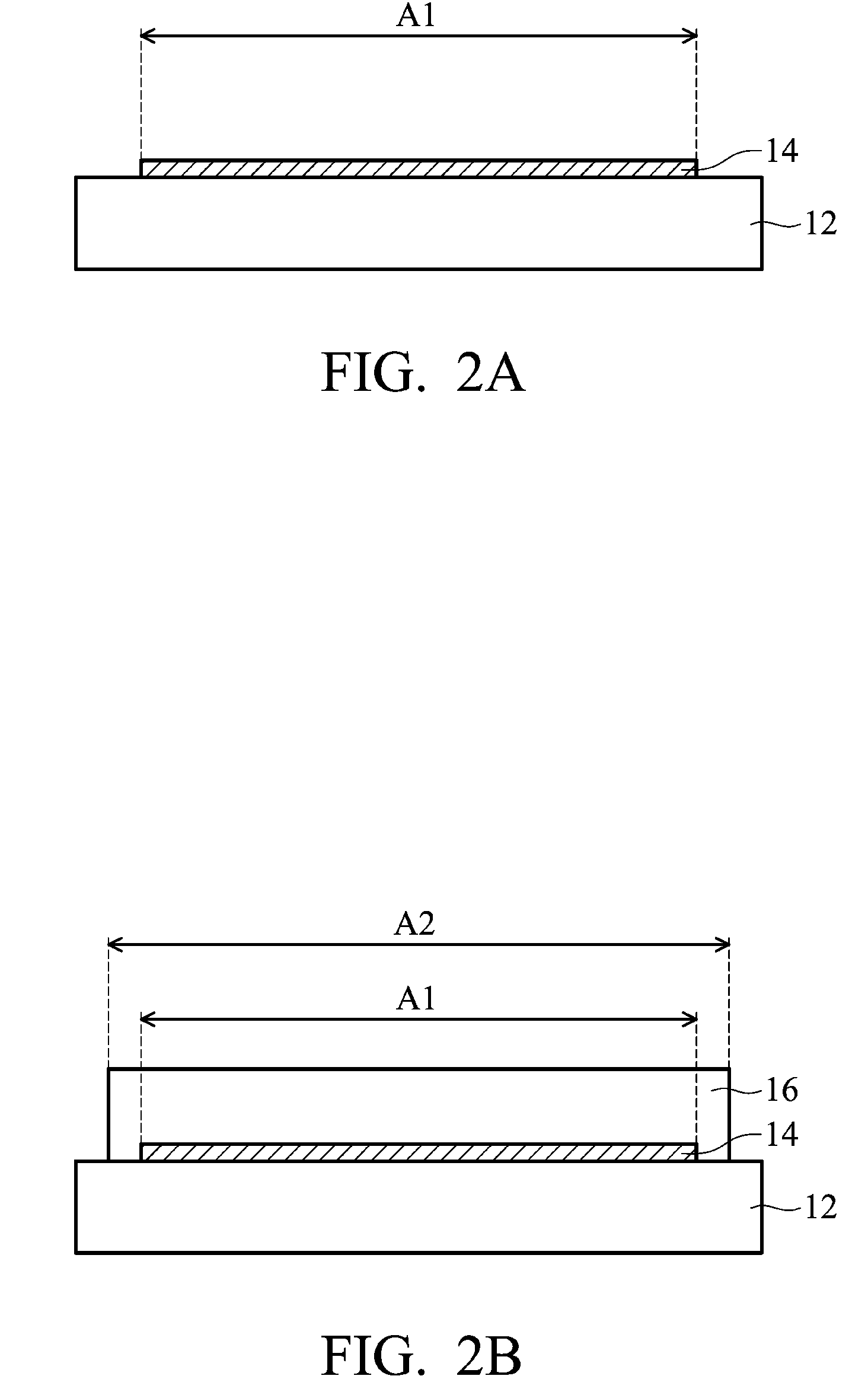

Preparation of parylene Release Layer

[0028]A parylene precursor (parylene dimer) was put into a thermal evaporation apparatus. A clean glass (15 cm×15 cm) covered with a hollow pad (8 cm×8 cm) was placed in a sample room. The parylene precursor was vaporized at 150° C. and decomposed at 650° C. in a vacuum and then conducted into the sample room. Parylene was deposited on the area uncovered by the pad at room temperature. A parylene release layer (8 cm×8 cm) was prepared.

example 2

Preparation of Arton, Topas and Zeonor Release Layer

[0029]Arton, Topas and Zeonor (with 10% solid content dissolved in toluene) were coated on glasses using a scraper. The glass was baked in various ovens (80° C. and 150° C.) respectively for 0.5 hour. A release layer (8 cm×8 cm) was prepared.

example 3

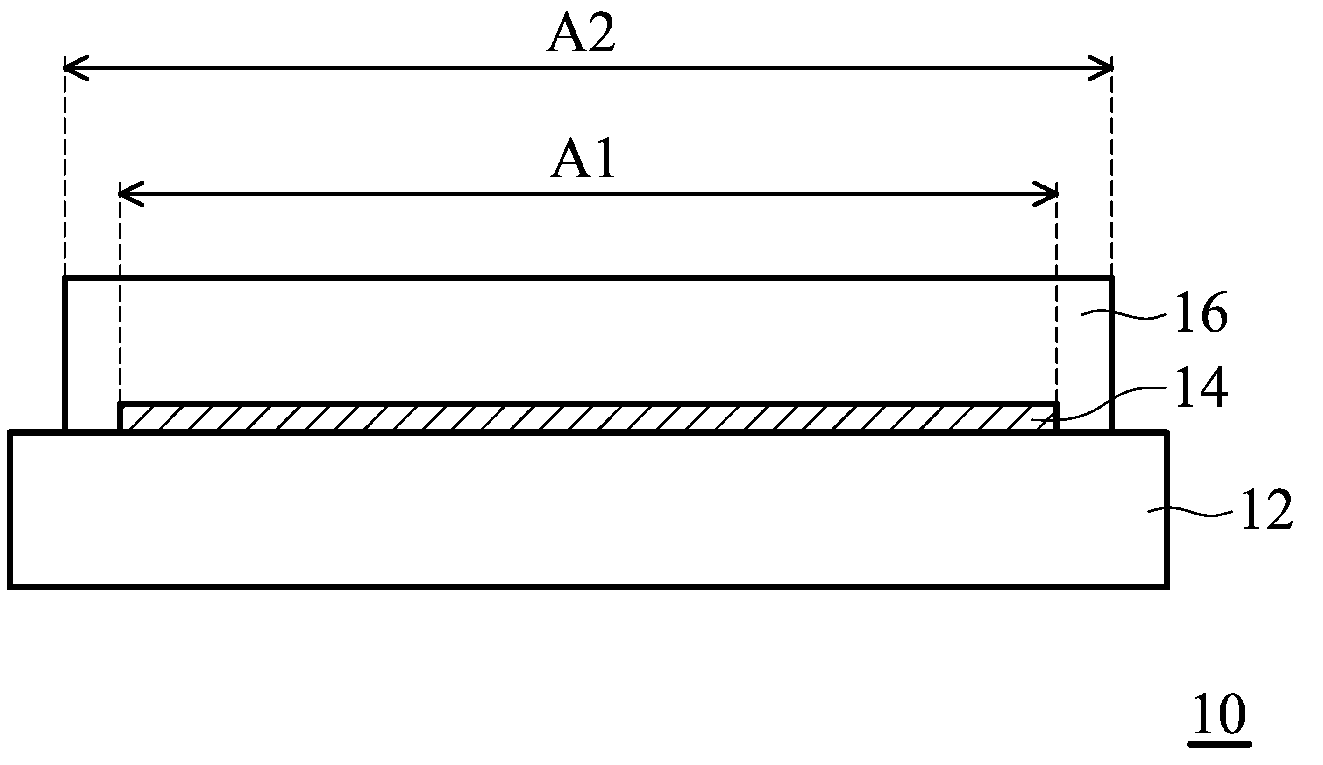

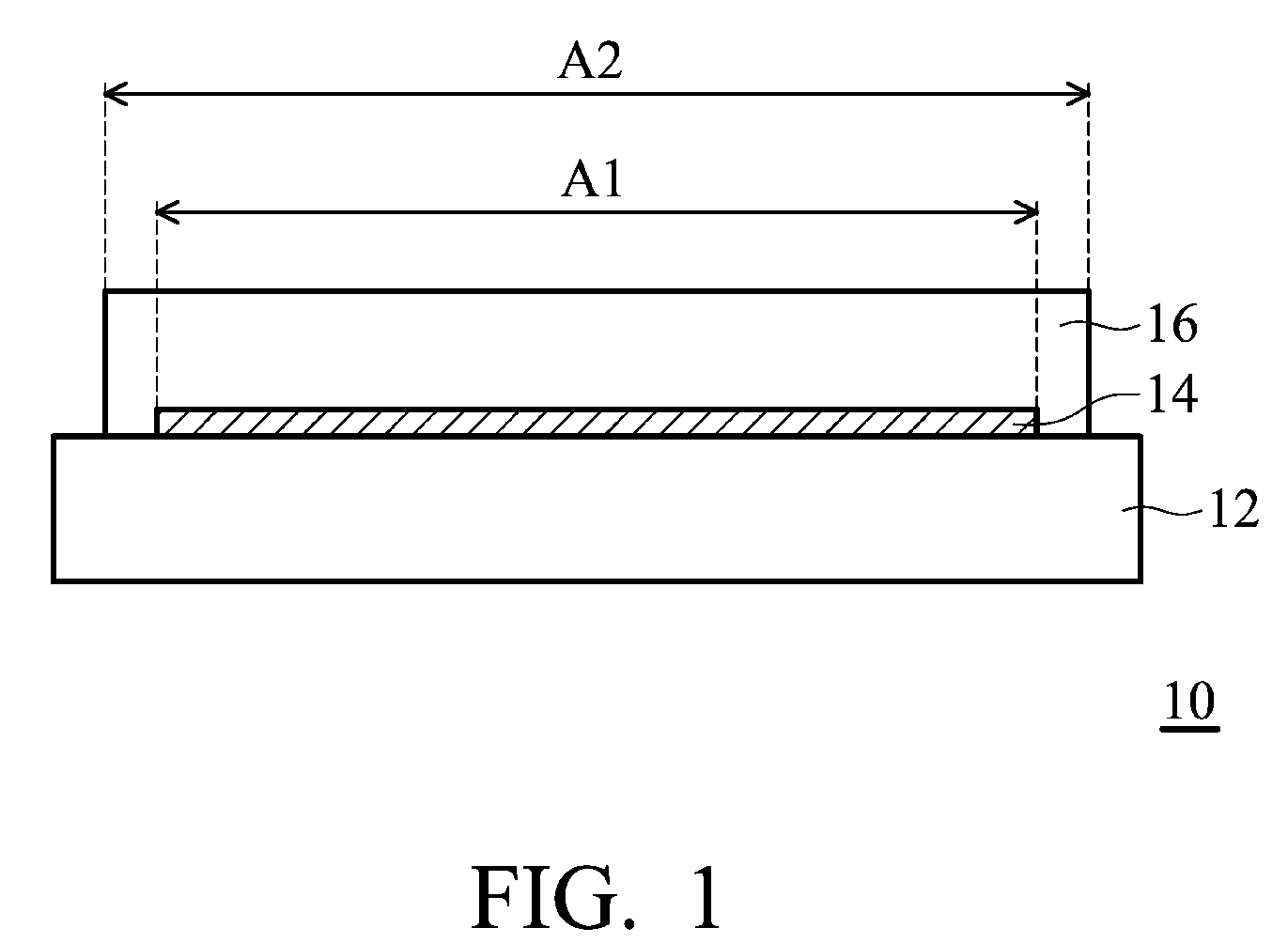

Preparation of polyimide (B1317-BAPPm, BB) / parylene / Glass Substrate Structure

[0030]

[0031]0.0147 mole diphenylamine (BAPPm) was completely dissolved in 32.94 g cresol under nitrogen at room temperature. 0.015 mole dianhydride (B1317) was then added and continuously stirred for 1 hour after dianhydride (B1317) was completely dissolved to form a sticky polyamic acid (PAA) solution. Next, the PAA solution was thermally imidized (220° C.) for 3 hours, and water was simultaneously removed. Methanol was finally added to the resulting solution to precipitate polyimide and baked in a vacuum oven for 12 hours. After baking, polyimide (with 20% solid content) was dissolved in DMAc to form a polyimide solution. The polyimide solution was then coated on the glass plated with 8 cm×8 cm parylene with an area (10 cm×10 cm) using a scraper. The glass was baked in various ovens (80° C. and 150° C.) respectively for 1 hour. A polyimide (BB) / parylene / glass substrate structure was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimensionless property | aaaaa | aaaaa |

| Digital information | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com