Water-based paint composition and preparation method thereof

A technology of water-based paint and composition, applied in the direction of anti-fouling/underwater paint, coating, paint containing biocide, etc., can solve the problems of large water environment pollution, bright spots, lack of water-based wall paint, etc., and achieve high Quality Anti-fouling and quality-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

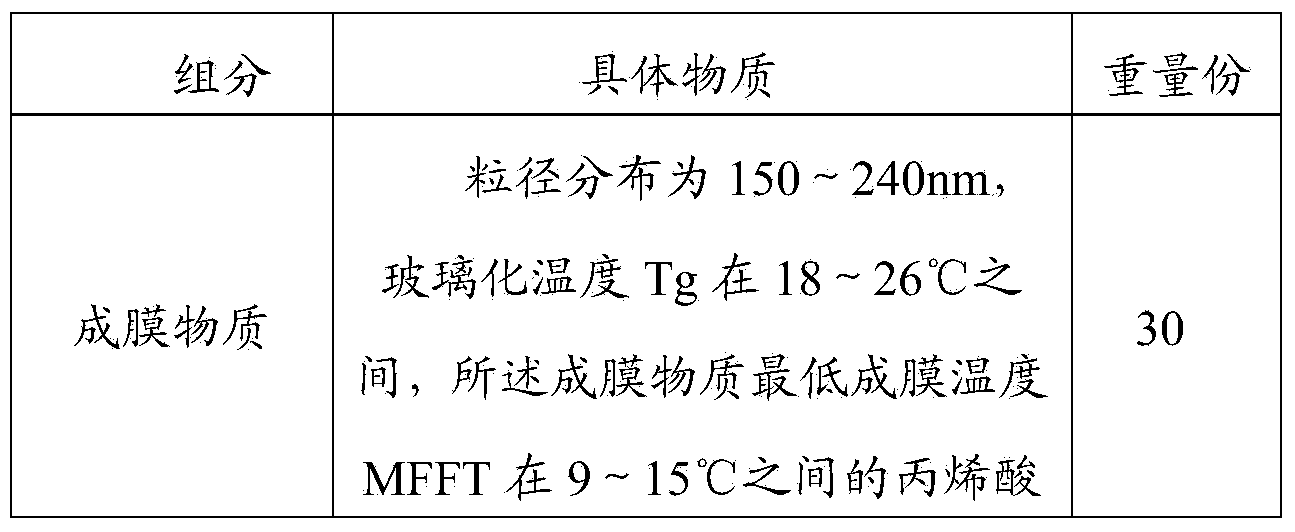

[0038] A kind of embodiment of water-based coating composition of the present invention, water-based coating composition described in the present embodiment comprises the component of following parts by weight:

[0039]

[0040]

[0041] The preparation method of aqueous paint composition described in the present embodiment may further comprise the steps:

[0042] (1) Put water into the dispersion tank, and control the speed at 400 rpm;

[0043] (2) Then add the defoamer and HASE hydrophobic dispersant additives into the dispersion tank in turn, and stir for 3 minutes;

[0044] (3) Add the pigments and fillers into the dispersion tank, increase the speed to 1200 rpm, and disperse at high speed for 12 minutes;

[0045] (4) After high-speed dispersion, reduce the speed to 600 rpm, add water, and stir for 4 minutes;

[0046] (5) Slowly add the film-forming substance and stir for 3 minutes;

[0047] (6) Then add co-solvent and film-forming aid and stir for 3 minutes;

[...

Embodiment 2

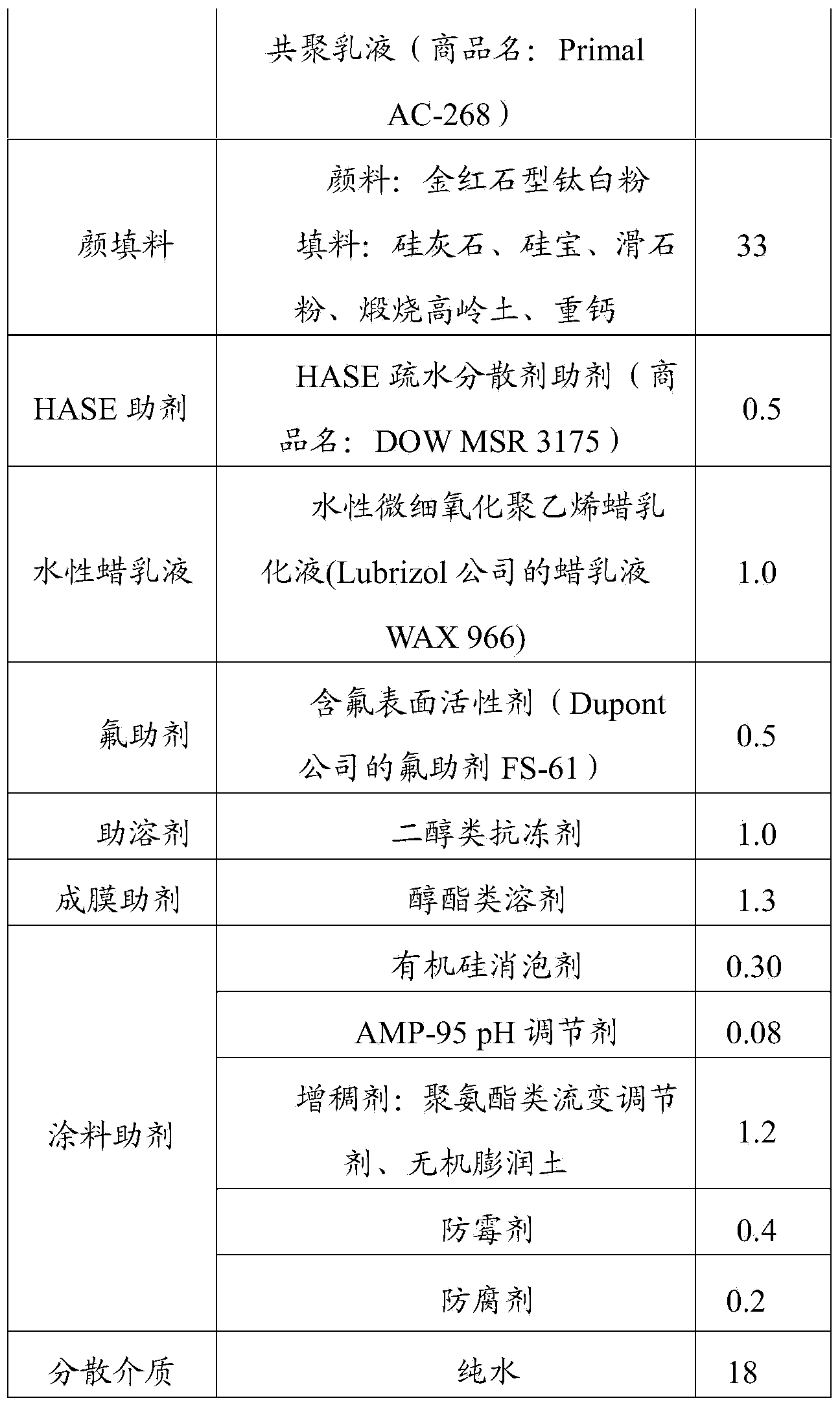

[0054] A kind of embodiment of water-based coating composition of the present invention, water-based coating composition described in the present embodiment comprises the component of following parts by weight:

[0055]

[0056]

[0057] The preparation method of aqueous paint composition described in the present embodiment may further comprise the steps:

[0058] (1) Put water into the dispersion tank, and control the speed at 300 rpm;

[0059] (2) Then add the defoamer and HASE hydrophobic dispersant additives into the dispersion tank in turn, and stir for 2 minutes;

[0060] (3) Add the pigment and filler into the dispersion tank, increase the speed to 1600 rpm, and disperse at high speed for 15 minutes;

[0061] (4) After high-speed dispersion, reduce the speed to 800 rpm, add water, and stir for 2 minutes;

[0062] (5) Slowly add the film-forming substance and stir for 5 minutes;

[0063] (6) Then add co-solvent and film-forming aid and stir for 2 minutes;

[00...

Embodiment 3

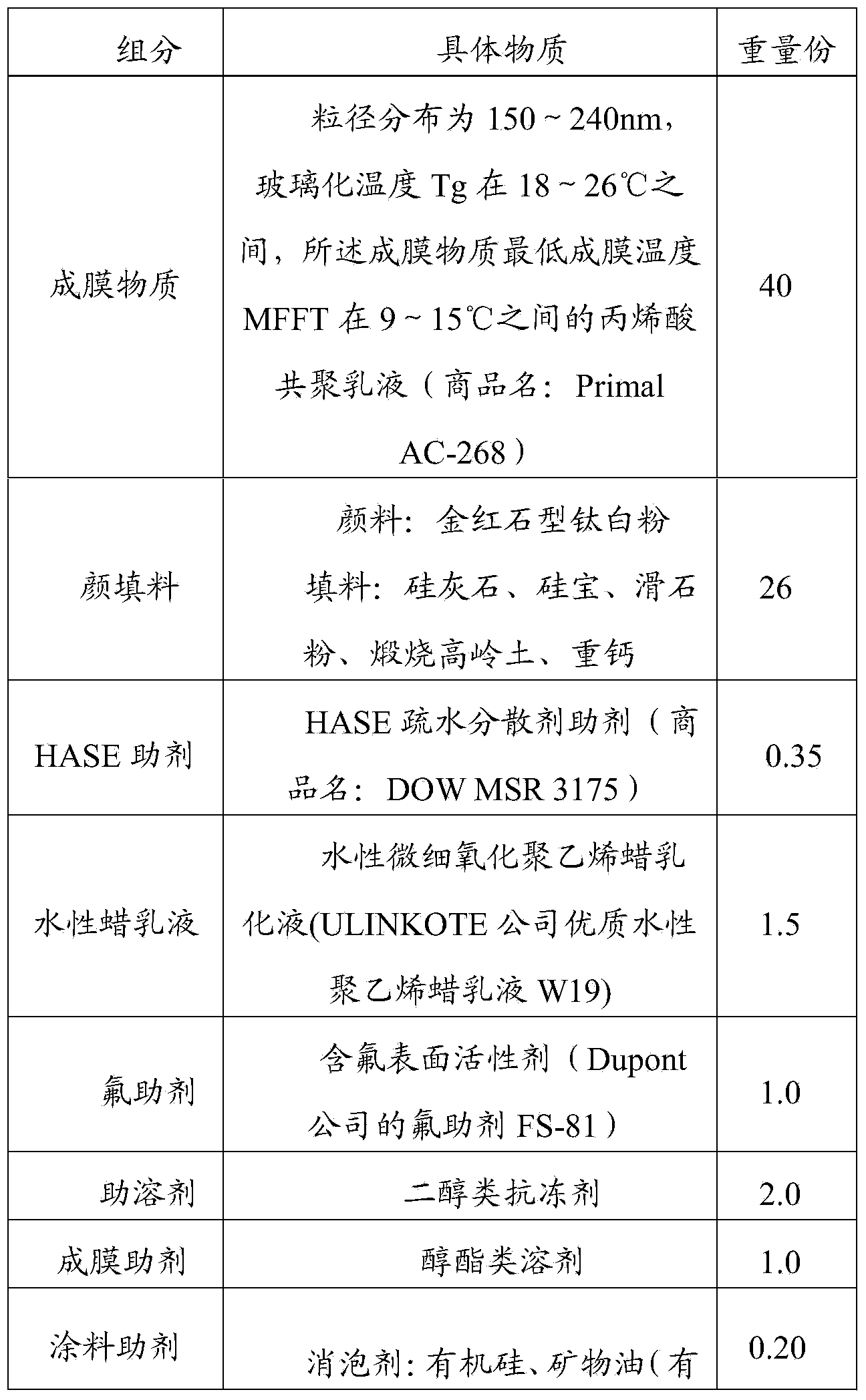

[0070] A kind of embodiment of water-based coating composition of the present invention, water-based coating composition described in the present embodiment comprises the component of following parts by weight:

[0071]

[0072]

[0073] The preparation method of aqueous paint composition described in the present embodiment may further comprise the steps:

[0074] (1) Put water into the dispersion tank, and control the speed at 500 rpm;

[0075] (2) Then add the defoamer and HASE hydrophobic dispersant additives into the dispersion tank in turn, and stir for 4 minutes;

[0076] (3) Add the pigments and fillers into the dispersion tank, increase the speed to 1800 rpm, and disperse at high speed for 18 minutes;

[0077] (4) After high-speed dispersion, reduce the speed to 700 rpm, add water, and stir for 3 minutes;

[0078] (5) Slowly add the film-forming substance and stir for 7 minutes;

[0079] (6) Then add co-solvent and film-forming aid, and stir for 4 minutes;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com