Two-component waterborne polyurethane industrial paint with excellent physical performance and preparation method thereof

A technology of water-based polyurethane and physical properties, applied in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor surface effect, high cost, good hardness, etc., to ensure excellent performance, high cost performance, The effect of high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The preparation method of the above-mentioned two-component waterborne polyurethane industrial paint with excellent physical properties comprises the following process steps:

[0078] Ⅰ. Preparation of component A: Add water, water-based hydroxyacrylic resin emulsion, water-based hydroxyurethane resin, dispersant, wetting agent, and part of defoamer to the dispersion tank, and disperse at a medium speed; then slowly add titanium dioxide and talc Powder, superfine calcium carbonate, sericite powder, aluminum zinc phosphomolybdate antirust pigment, add water to wash the tank wall, disperse at high speed for 20-50 minutes until the fineness is ≤50 microns; then add organic bismuth / Zinc composite catalyst, leveling agent, thickener, alkoxysilane adhesion promoter and the rest of the defoamer, dispersed at a medium speed for 20 to 40 minutes; take samples to test the fineness and viscosity of the finished product, filter and pack to obtain Group A point.

[0079] Ⅱ. Prepar...

Embodiment 1

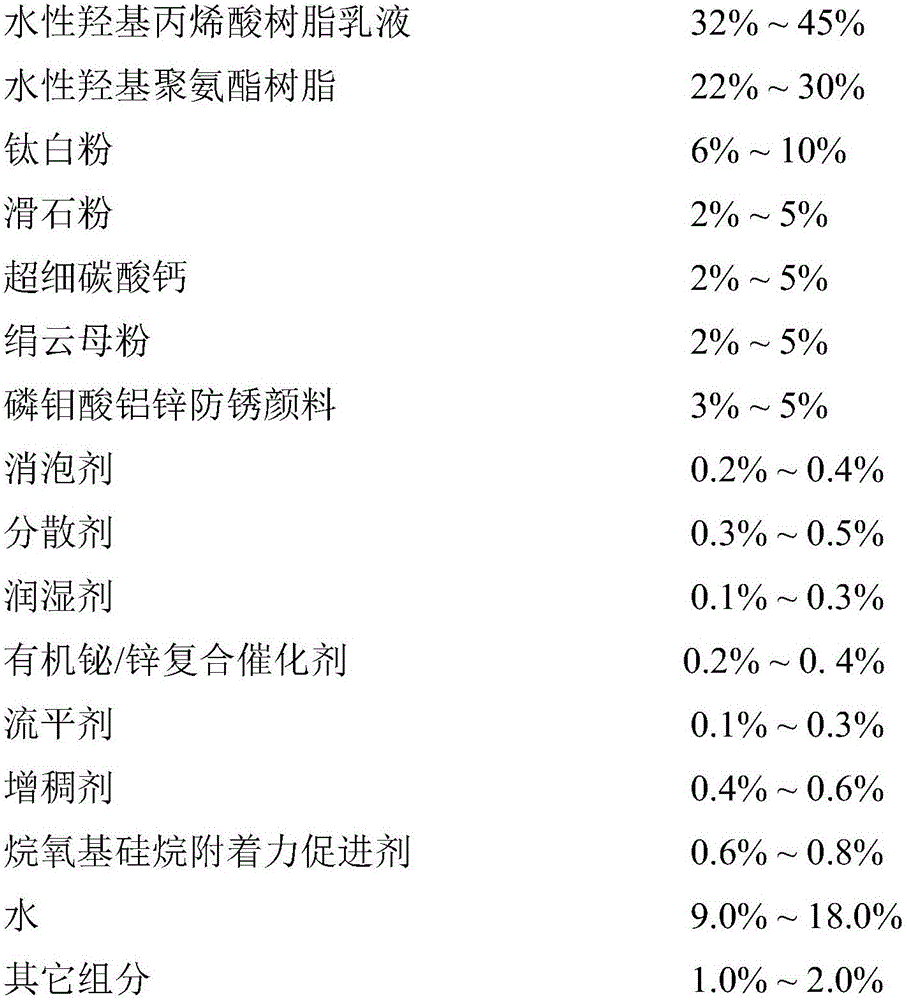

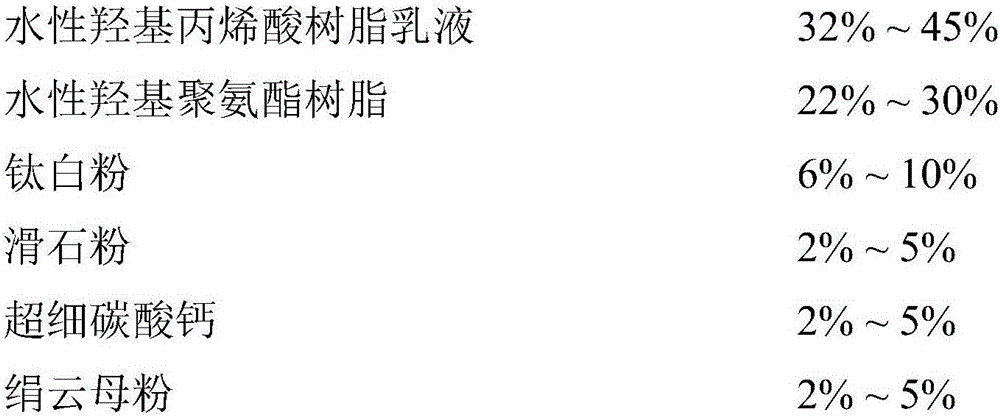

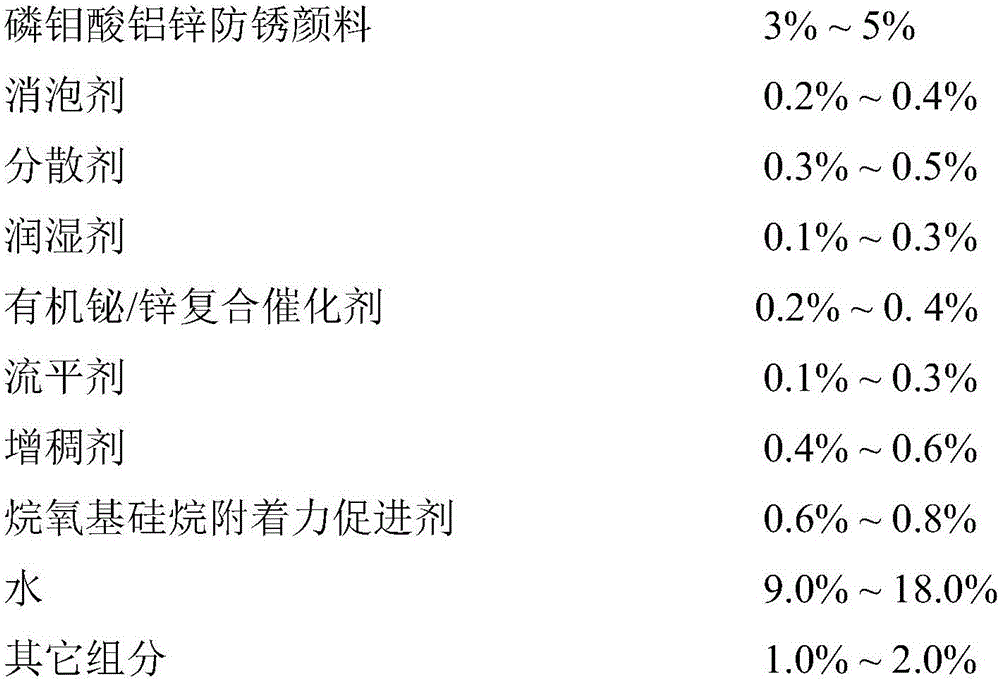

[0085] A two-component waterborne polyurethane industrial paint with excellent physical properties consists of the following components by weight percentage:

[0086] A component

[0087]

[0088]

[0089] Wherein the weight percentage sum of A component is 100%.

[0090] B component

[0091] Sulfonate modified HDI trimer 100%

[0092] Wherein the sum of weight percentages of component B (curing agent) is 100%.

[0093] Component A (main paint) and component B (curing agent) are mixed according to the NCO / OH equivalent ratio of n(-NCO):n(-OH)=1.3, that is, the -NCO functional group in component A and component B The molar ratio of equivalents of -OH functional groups in a part is 1.3.

[0094] Process steps for preparing the above-mentioned two-component waterborne polyurethane industrial paint with excellent physical properties:

[0095] 1. Preparation of component A: Weigh the raw materials according to the weight percentage of the above components, add water, wat...

Embodiment 2

[0100] A two-component waterborne polyurethane industrial paint with excellent physical properties consists of the following components by weight percentage:

[0101] A component

[0102]

[0103] Wherein the weight percentage sum of A component is 100%.

[0104] B component

[0105] Sulfonate modified HDI trimer 100%

[0106] Wherein the sum of weight percentages of component B (curing agent) is 100%.

[0107] Component A (main paint) and component B (curing agent) are mixed according to the NCO / OH equivalent ratio of n(-NCO):n(-OH)=1.3, that is, the -NCO functional group in component A and component B The molar ratio of equivalents of -OH functional groups in a part is 1.3.

[0108] Process steps for preparing the above-mentioned two-component waterborne polyurethane industrial paint with excellent physical properties:

[0109] 1. Preparation of component A: Weigh the raw materials according to the weight percentage of the above components, add water, water-based hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com