Electrically-conducting paint based on TiB2 and its preparation method and application

A technology of conductive coatings and conductive powders, applied in conductive coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of high resistance of metal compounds, poor electrical properties of carbon-based fillers, poor heat and humidity resistance, etc., to achieve electrical conductivity. Excellent, strong thermal conductivity, excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] raw material name

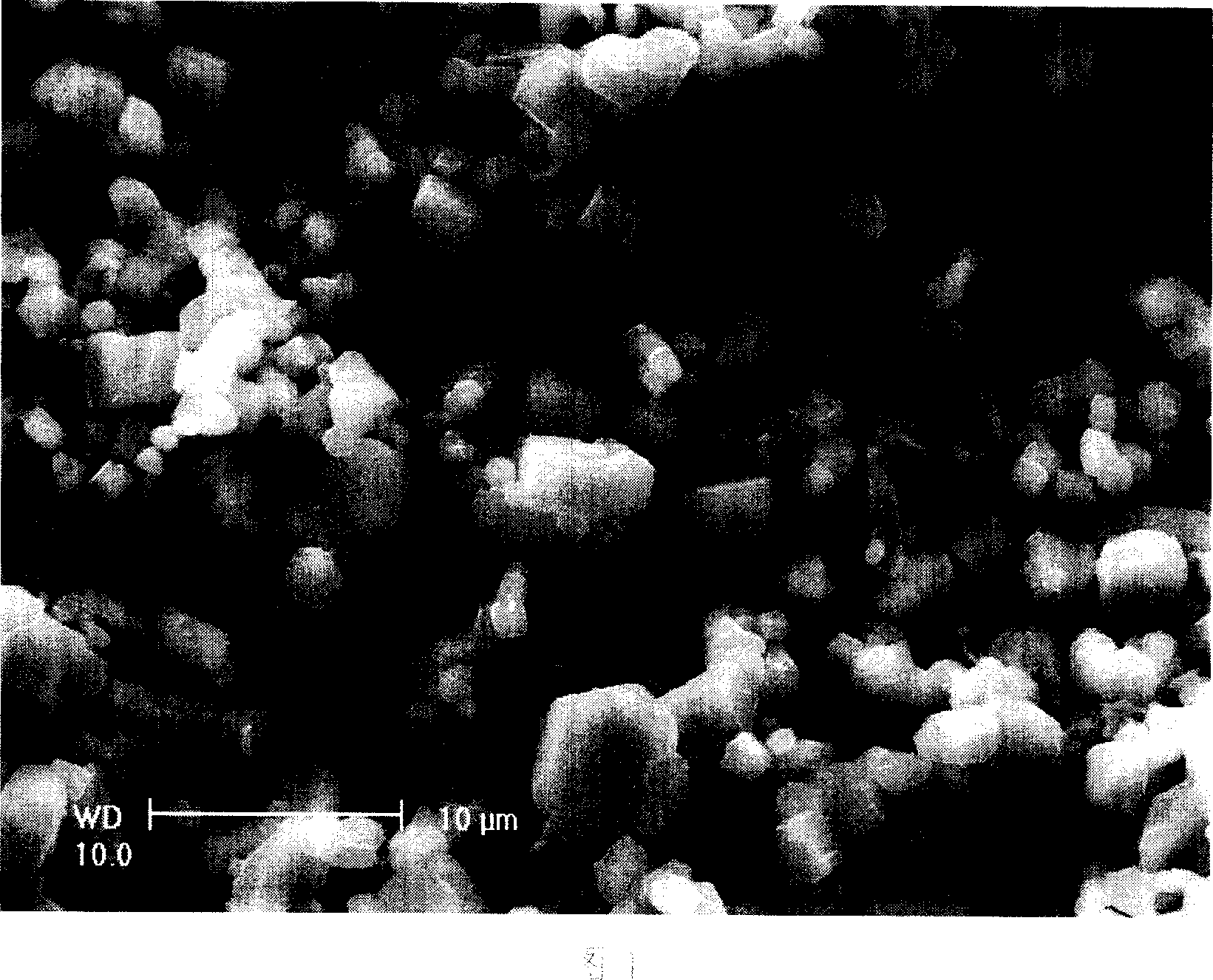

[0040] Stir and disperse the above raw materials in proportion to prepare conductive coating. If the conductive powder is pure TiB 2 (purity greater than 98% wt, particle size 2 ~ 10μm), then the conductivity is 0.5Ω.cm, if the conductive powder is TiB 2 : graphite: acetylene black = 1: 0.2: 0.1 weight ratio, then the conductivity is 0.6Ω.cm. The coating (coating thickness is about 80 μm) is coated with A3 carbon steel for about 1000 hours, and for magnesium (magnesium alloy AZ91D) for about 280 hours. Alloy) has a neutral salt spray resistance time of about 800h, and coated copper (copper alloy) has a neutral salt spray resistance time of about 880h. As shown in Figure 1, TiB used in the present invention 2 scanning electron microscope photographs.

Embodiment 2

[0042] Difference with embodiment 1 is that the basic formula of this conductive paint is:

[0043] raw material name

[0044] Stir and disperse the above raw materials in proportion to prepare conductive coating. If the conductive powder is pure TiB 2 , the conductivity is 0.5Ω.cm, if the conductive powder uses TiB 2 : graphite: carbon black=1:0.2:0.1 weight ratio, then the electrical conductivity is 1.0Ω.cm. The coating (coating thickness is about 80 μm) is coated with A3 carbon steel for about 1000 hours, and for magnesium (magnesium alloy AZ91D) for about 280 hours. Alloy) has a neutral salt spray resistance time of about 800h, and coated copper (copper alloy) has a neutral salt spray resistance time of about 880h.

Embodiment 3

[0046] Difference with embodiment 1 is that the basic formula of this conductive paint is:

[0047] raw material name

[0048] The difference from Example 1 is that the above raw materials are stirred and dispersed in proportion to prepare a conductive coating. The curing temperature is 300-350°C, and the curing time is 2-5 hours. If the conductive powder is pure TiB 2 , the conductivity is 0.3Ω.cm, if the conductive powder uses TiB 2 : graphite: carbon black=1:0.2:0.1 weight ratio, then the electrical conductivity is 1.1Ω.cm. The coating (coating thickness is about 80 μm) is coated with A3 carbon steel for about 1200 hours, and for magnesium (magnesium alloy AZ91D) for about 320 hours. Alloy) has a neutral salt spray resistance time of about 1000h, and coated copper (copper alloy) has a neutral salt spray resistance time of about 880h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com