Method for recycling waste paint slag of water-soluble paint

A water-soluble, paint-based technology, applied in the direction of coating, etc., to achieve the effect of recycling, good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

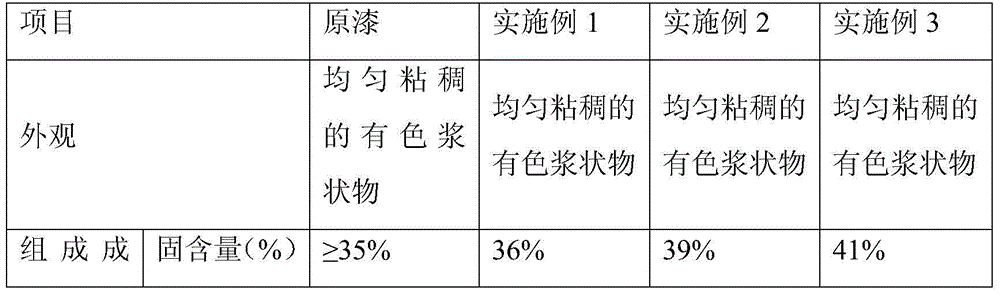

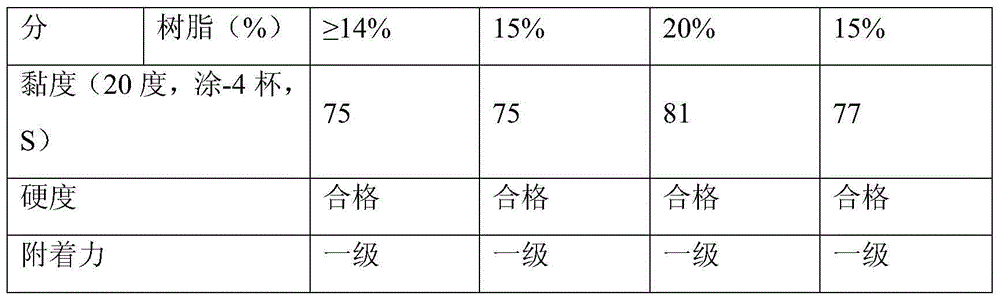

Embodiment 1

[0045] Recycling of pigments and resins: First, simply remove mechanical impurities and foreign matter in the mixed paint slag solution in the recovery tank, add 6mol / L dilute hydrochloric acid, and adjust the pH to 3. After standing overnight, the mixture was filtered, and the filtrate I was discharged into the waste liquid tank for conventional sewage treatment. Add deionized water to the filter residue I at a mass ratio of 1:1, adjust the pH to 11 with industrial ammonia water, stir evenly, let it stand for 3 hours, filter, collect the filter residue II and dry it to obtain the recovered pigment, and filter the obtained filtrate II Concentrate by evaporation to obtain a resin solution with a solid content of 30%.

[0046] Regeneration preparation of water-soluble paint: take 12 parts of recycled pigments, add 0.5 parts of fatty alcohol polyoxyethylene ether dispersant, 2 parts of Joncry 120 grinding resin, 15 parts of isopropanol, 1 part of silicone defoamer, deionized 7 p...

Embodiment 2

[0048] Recycling of pigments and resins: First, simply remove mechanical impurities and foreign matter in the mixed paint slag solution in the recovery tank, add 1mol / L dilute hydrochloric acid, and adjust the pH to 5. After standing overnight, the mixture was filtered, and the filtrate I was discharged into the waste liquid tank for conventional sewage treatment. Add deionized water to the filter residue I at a mass ratio of 1:1.5, adjust the pH to 8 with industrial ammonia water, stir evenly, let it stand for 2 hours, filter, collect the filter residue II and dry it to obtain the recovered pigment, and filter the obtained filtrate II Concentrate by evaporation to obtain a resin solution with a solid content of 25%.

[0049] Regeneration preparation of water-soluble paint: Take 12 parts of recycled pigments, add 5 parts of sodium polystyrene sulfonate dispersant, 10 parts of Joncry 120 grinding resin, 5 parts of ethylene glycol, 1 part of silicone defoamer, deionized 15 part...

Embodiment 3

[0051] Recycling of pigments and resins: First, simply remove mechanical impurities and foreign matter in the mixed paint slag solution in the recovery tank, add 4mol / L dilute hydrochloric acid, and adjust the pH to 3.5. After standing overnight, the mixture was filtered, and the filtrate I was discharged into the waste liquid tank for conventional sewage treatment. Add deionized water to the filter residue I at a mass ratio of 1:2, adjust the pH to 10 with industrial ammonia water, stir evenly, let it stand for 2 hours, filter, collect the filter residue II and dry it to obtain the recovered pigment, and circulate the obtained filtrate II Use it to treat filter residue I to obtain a resin solution with a solid content of 30%.

[0052] Regeneration preparation of water-soluble paint: Take 12 parts of recycled pigments, add 2 parts of sodium polystyrene sulfonate dispersant, 5 parts of S-90 grinding resin, 5 parts of isopropanol, 1 part of silicone defoamer, 15 parts of deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com