Low-temperature curing flame-retardant finishing powder paint and preparation method thereof

A powder coating, low temperature technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of no flame retardant effect and low temperature curing, achieve good fire protection effect, improve fire resistance and flame retardant. Ability, good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

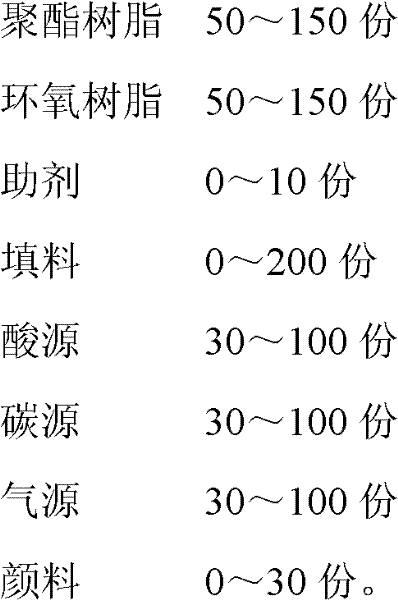

[0033] A low-temperature curing and flame-retardant and fireproof decorative powder coating, its components and weight ratio are as follows:

[0034]

[0035] Preparation:

[0036] (1) Weigh saturated carboxyl polyester resin, bisphenol A epoxy resin, barium sulfate, acrylate leveling agent 502, benzoin, breather 703, brightening agent 701, ammonium polyphosphate, pentaerythritol, melamine and Put the carbon black in the mixer, fully mix and crush for 1 to 5 minutes;

[0037] (2) The crushed material enters the twin-screw extruder for extrusion; the heating temperature of the extruder is controlled at 80-90°C;

[0038] (3) The extruded material is compressed into tablets, cooled, pulverized into a powder with an equivalent particle diameter D50 of 50 microns, and then sieved and packed.

Embodiment 2

[0040] A low-temperature curing and flame-retardant and fireproof decorative powder coating, its components and weight ratio are as follows:

[0041]

[0042] Preparation:

[0043] (1) Take saturated carboxyl polyester resin, bisphenol A type epoxy resin, barium sulfate, calcium carbonate, titanium dioxide, acrylate leveling agent 502, ammonium polyphosphate, dipentaerythritol, melamine and carbon black in proportion In the mixing tank, fully mix and crush for 1 to 5 minutes;

[0044] (2) The crushed material enters the twin-screw extruder for extrusion; the heating temperature of the extruder is controlled at 80-90°C;

[0045] (3) The extruded material is compressed into tablets, cooled, pulverized into a powder with an equivalent particle diameter D50 of 50 microns, and then sieved and packed.

Embodiment 3

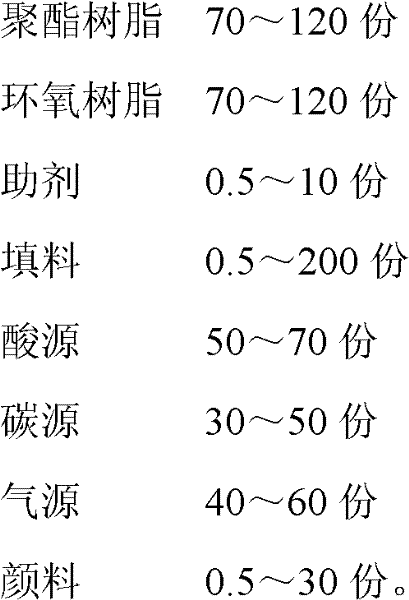

[0047] A low-temperature curing and flame-retardant and fireproof decorative powder coating, its components and weight ratio are as follows:

[0048]

[0049]

[0050] Preparation:

[0051] (1) Weigh saturated carboxyl polyester resin, bisphenol A type epoxy resin, barium sulfate, titanium dioxide, acrylate leveling agent 502, benzoin, breathable agent 703, brightening agent 701, ammonium polyphosphate, pentaerythritol Put it in a mixer with melamine, mix thoroughly and crush for 1 to 5 minutes;

[0052] (2) The crushed material enters the twin-screw extruder for extrusion; the heating temperature of the extruder is controlled at 80-90°C;

[0053] (3) The extruded material is compressed into tablets, cooled, pulverized into a powder with an equivalent particle diameter D50 of 50 microns, and then sieved and packed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com