UV-curable ink used in inkjet printing direct-to-plate, and preparation method and application thereof

A technology of inkjet printing and ink, which is applied in the field of UV curing ink and its preparation of inkjet printing direct plate-making technology, and can solve the problems of affecting printing plate durability, image resolution, image drop-out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

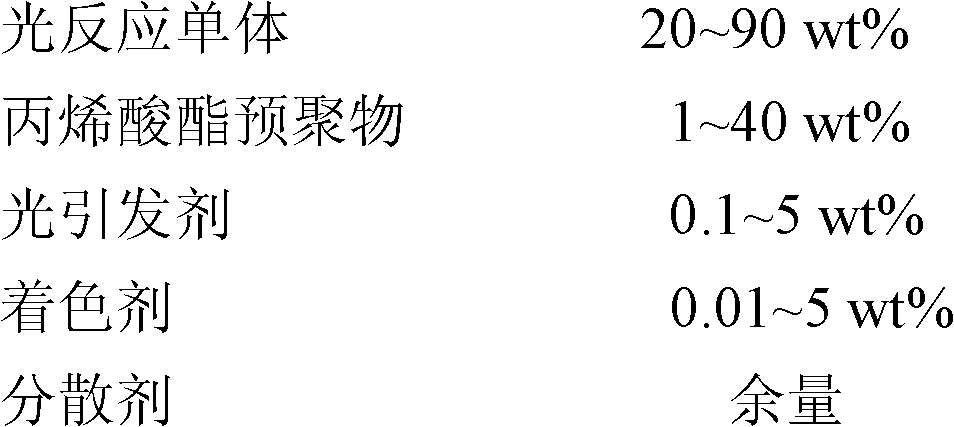

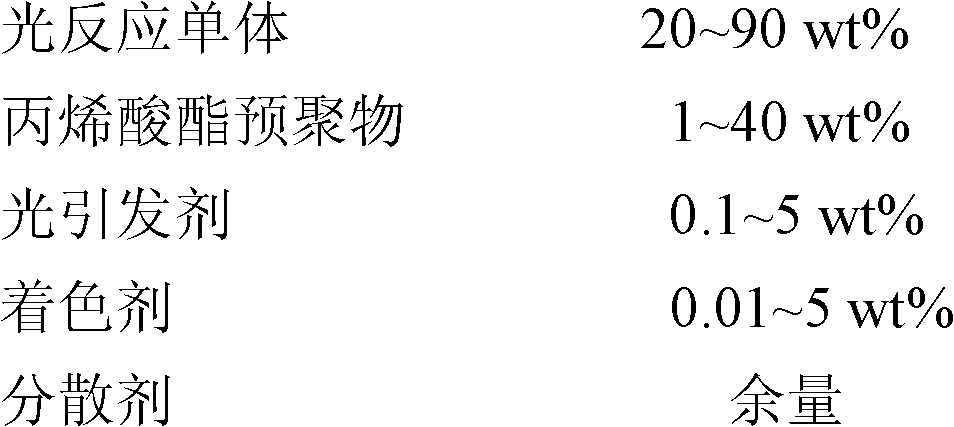

Method used

Image

Examples

Embodiment 1

[0024] 40wt% of hydroxypropyl acrylate, 40wt% of urethane acrylate prepolymer, 0.1wt% of benzoin isobutyl ether, 0.01wt% of Pigment Violet-19, and the balance Disperbyk101 is mixed; it is ground with a grinding equipment for 2 hours at room temperature, and after multi-stage filtration, the filtrate is UV curable ink.

Embodiment 2

[0026] 90wt% butyl acrylate, 1wt% polyester acrylate prepolymer, 5wt% 2-isopropylacetophenone, 2wt% Pigment Black-7, and the balance Efka 44 Mixing; Grind with grinding equipment at room temperature for 15 hours, after multi-stage filtration, the filtrate is UV curing ink.

Embodiment 3

[0028] 50wt% of acryloyl morpholine, 40wt% of pentaerythritol tetraacrylate, 5wt% of urethane acrylate prepolymer, 1wt% of 2,4-diethylthioxanthone, 2wt% of the total UV curable ink The oil-soluble black, and the remainder of Efka 46 are mixed; it is ground for 10 hours with a grinding equipment at room temperature, after multi-stage filtration, the filtrate is UV curing ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com