Nanometer cellulose functional doped modified paint and preparation method thereof

A nano-scale cellulose and nano-cellulose technology, applied in polyester coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., can solve problems such as cracks in coatings, aesthetics, and house leakage, and achieve protection and safety , improve quality and performance, increase the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A nanoscale cellulose functional doped modified coating and a preparation method thereof, comprising the following steps and process conditions:

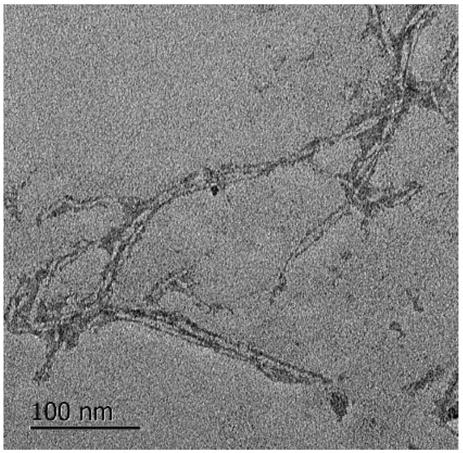

[0017] (1) Preparation of nanocellulose: Separate nanocellulose with a diameter of 10 nm from pine raw materials by purely mechanical methods, and mix it uniformly in a high-speed shearing machine at room temperature to form a water-based solution with a mass fraction of 0.01%. The main purpose of nanocellulose dispersion is to meet the interface requirements of different water-based coatings.

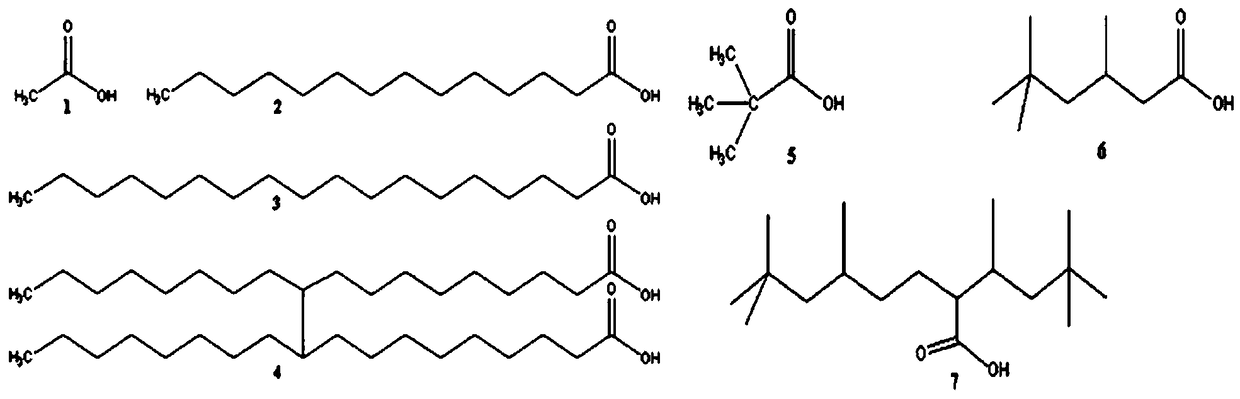

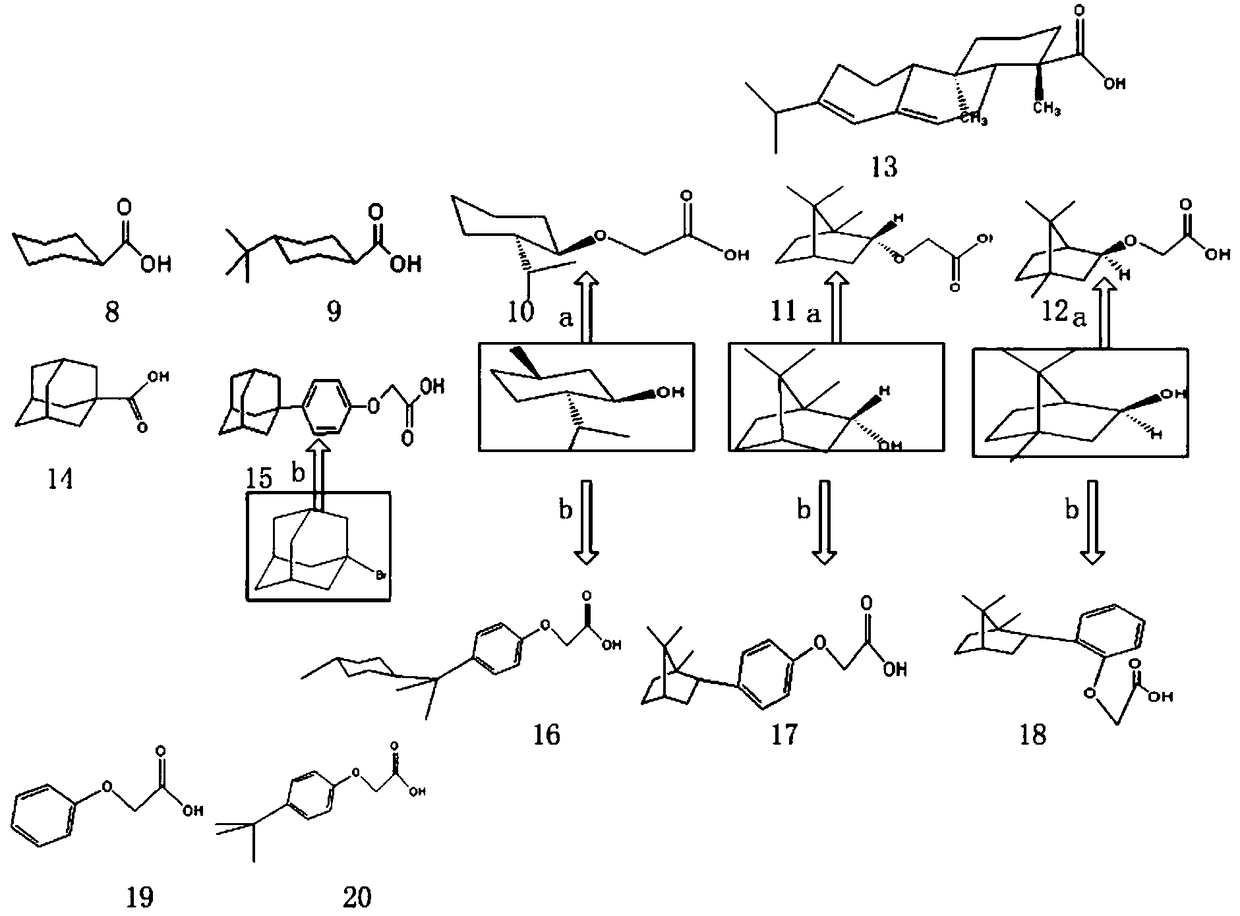

[0018] (2) Nanocellulose modification process: After stirring and mixing nanocellulose and sodium chloroacetate according to the mass ratio of 1:4 and dispersing them in water, raise the temperature to 90°C, react for 5 hours, and then remove the residual water-soluble The modified reagent and its by-products were used to disperse the reacted nanocellulose in water to obtain a hydrophilic nanocellulose dispersion A with a mass fractio...

Embodiment 2

[0025] A nanoscale cellulose functional doped modified coating and a preparation method thereof, comprising the following steps and process conditions:

[0026] (1) Preparation of nanocellulose: The nanocellulose with a diameter of 50nm is separated from the poplar raw material by TEMPO oxidation pretreatment in parallel with mechanical homogenization. The main purpose of functional modification is to adapt to different solvent-based coatings. Interface requirements.

[0027] (2) Nanocellulose modification process: Mix nanocellulose and dodecyl carboxylic acid modification agent according to the mass ratio of 1:3, stir and mix them and disperse them in absolute ethanol, then raise the temperature to 150°C , reacted for 3 h, and then dispersed the reacted nanocellulose in ethanol by removing the residual modifying reagent and its by-products to obtain a hydrophobic nanocellulose dispersion B with a mass fraction of 0.1%.

[0028] (3) Preparation of nanocellulose-doped coating:...

Embodiment 3

[0033] A nanoscale cellulose functional doped modified coating and a preparation method thereof, comprising the following steps and process conditions:

[0034] (1) Preparation of nanocellulose: Nanocellulose with a diameter of 30 nm is separated from straw raw materials by a purely mechanical method, dispersed in an aqueous solution, and the main purpose of functionalization is to adapt to the interface requirements of different water-based coatings.

[0035](2) Nanocellulose modification process: After stirring and mixing nanocellulose and chloroacetic acid according to the mass ratio of 1:4 and dispersing them in water, the temperature was raised to 80°C, reacted for 2 hours, and then modified by removing residual water-soluble Reactive reagents and their by-products were dispersed into water after the reaction to obtain a hydrophilic nanocellulose dispersion A with a mass fraction of 0.1%.

[0036] (2) Preparation of nanocellulose-doped coating: amino resin film-forming ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com