Heat-resistant phenolic resin produced by taking cresol residues as raw material and application of heat-resistant phenolic resin in heat-resistant anti-corrosion paint

A technology of phenolic resin and raw materials, which is applied in the production of heat-resistant anti-corrosion paint. In the field of heat-resistant phenolic resin, it can solve the problems of toxic and harmful substance discharge, zero pollution discharge, and complicated treatment process, etc., and achieve good adhesion , strong implementability and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

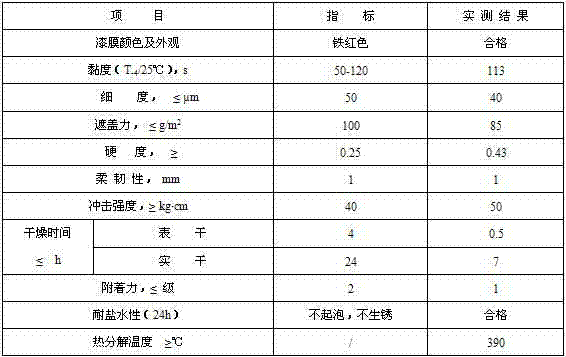

Embodiment 1

[0047] 1. Preparation of heat-resistant phenolic resin

[0048] (1) Accurately weigh 100 parts of cresol residue, 50 parts of furan resin, 100 parts of dicyclopentadiene, 50 parts of water, 0.2 part of zinc oxide, and 0.6 part of hexamethylenetetramine, add them to the reaction kettle, heat up, and when When the system reaches 90°C, add 50 parts of formaldehyde dropwise; after dropping, keep at this temperature for 3 hours to make it fully react; then add 60 parts of pentaerythritol and 40 parts of maleic anhydride, continue to heat up, at After keeping at ℃ for 2 hours, start to measure the acid value, oil solubility and solubility. When the acid value is ≤20mgKOH / g, resin: linseed oil = 1:4, fully soluble, resin: toluene = 1:1, fully soluble, it is qualified . Start to discharge, dry, and crush to obtain hard resin, which is set aside.

[0049](2) Put 300 parts of the above-mentioned hard resin, 100 parts of tung oil, 50 parts of pentaerythritol, 60 parts of phthalic anhyd...

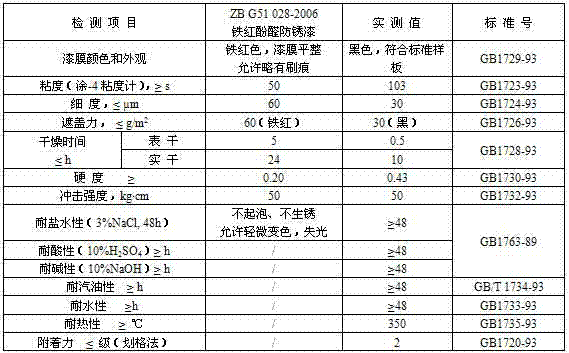

Embodiment 2

[0062] 1. Preparation of heat-resistant phenolic resin

[0063] (1) Accurately weigh 100 parts of cresol residue, 50 parts of dimethylcyclopentadiene, 100 parts of terpene resin, 50 parts of water, 1 part of lead oxide, and 2 parts of ammonia water, add them to the reaction kettle, heat up, and when the system When it reaches 90°C, add 50 parts of formaldehyde dropwise; after dropping, keep it at this temperature for 5 hours to make it fully react; detect the oil solubility and solubility of the resin (resin: linseed oil = 1:4, fully soluble; resin: Toluene = 1:1, fully soluble), complete dissolution is qualified, discharge, dry, crush to obtain hard resin, set aside.

[0064] (2) Heat up 200 parts of the above-mentioned hard resin, 100 parts of linseed oil, 45 parts of pentaerythritol, 0.2 parts of lead oxide, and 0.1 part of lithium hydroxide to 240°C, and keep it for 2 hours to detect alcohol solubility. When the resin: ethanol (95% ) ≥ 1:5 is qualified, then lower the tem...

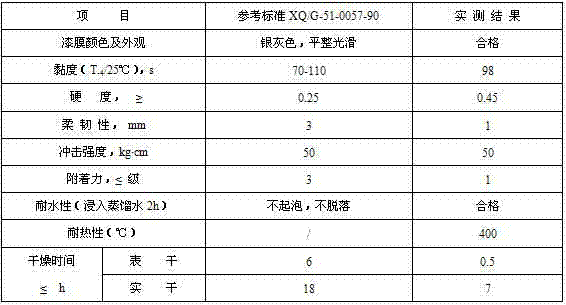

Embodiment 3

[0077] 1. Preparation of heat-resistant phenolic resin

[0078] (1) Accurately weigh 100 parts of cresol residue, 50 parts of rosin, 200 parts of coumarone resin, 50 parts of water, 1 part of zinc oxide, and 1 part of ammonia water, add them to the reaction kettle, and raise the temperature. When the system reaches 90 °C, Add 50 parts of formaldehyde dropwise; after dropping, keep it at this temperature for 5 hours to make it fully react; after passing the test (test oil solubility and solubility, resin: linseed oil = 1:4, fully soluble; resin: toluene = 1:1, fully soluble), discharge, dry, and crush to get hard resin, set aside;

[0079] (2) Heat 350 parts of the above-mentioned hard resin, 200 parts of linseed oil, 60 parts of pentaerythritol, 20 parts of trimethylolpropane, 0.1 part of lithium hydroxide, and heat up to 250 ° C. After keeping it for 1 hour, test the alcohol solubility. When the resin: ethanol (95%)≥1:5 is qualified, then lower the temperature to 200°C, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com