Silane-containing corrosion protection coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

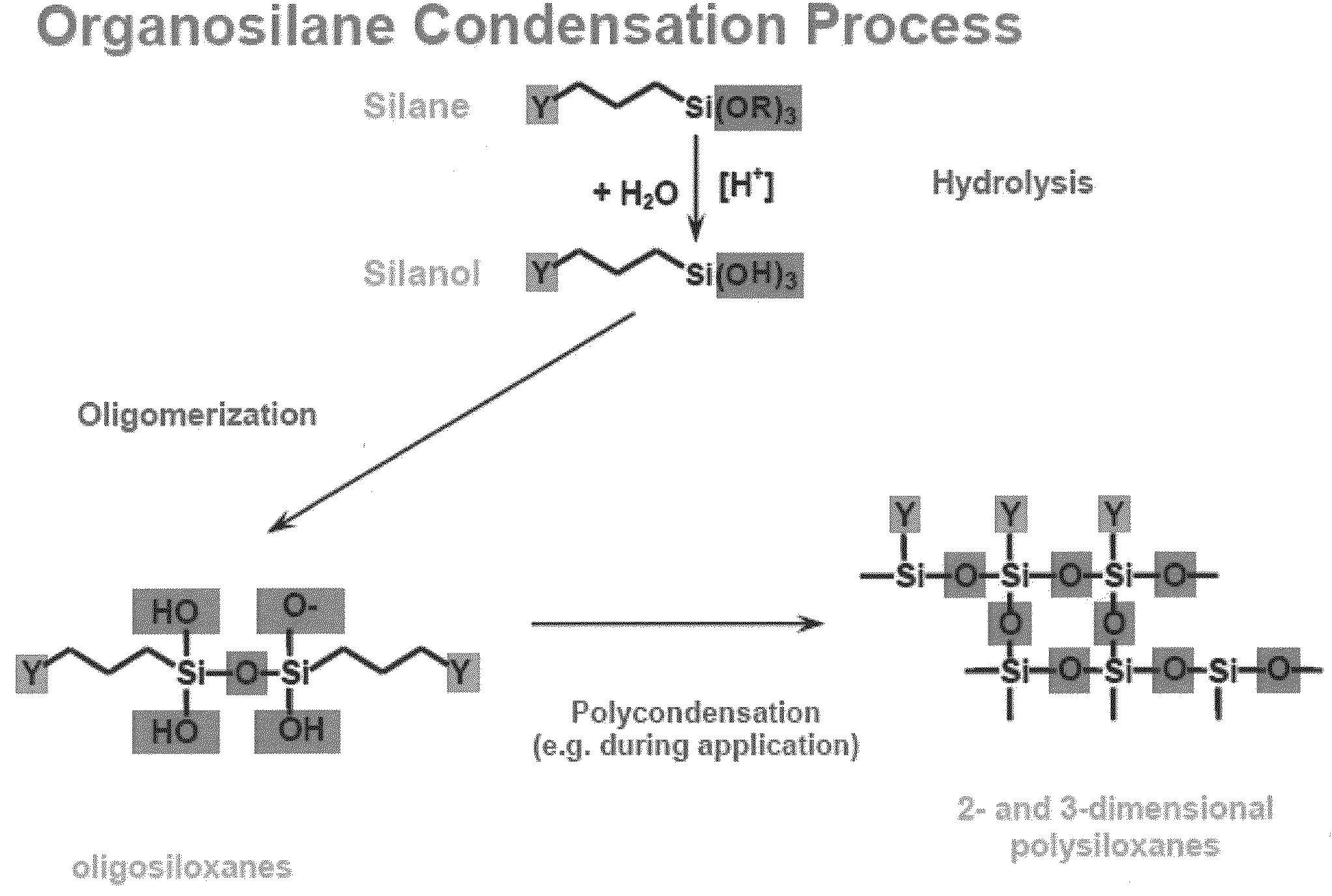

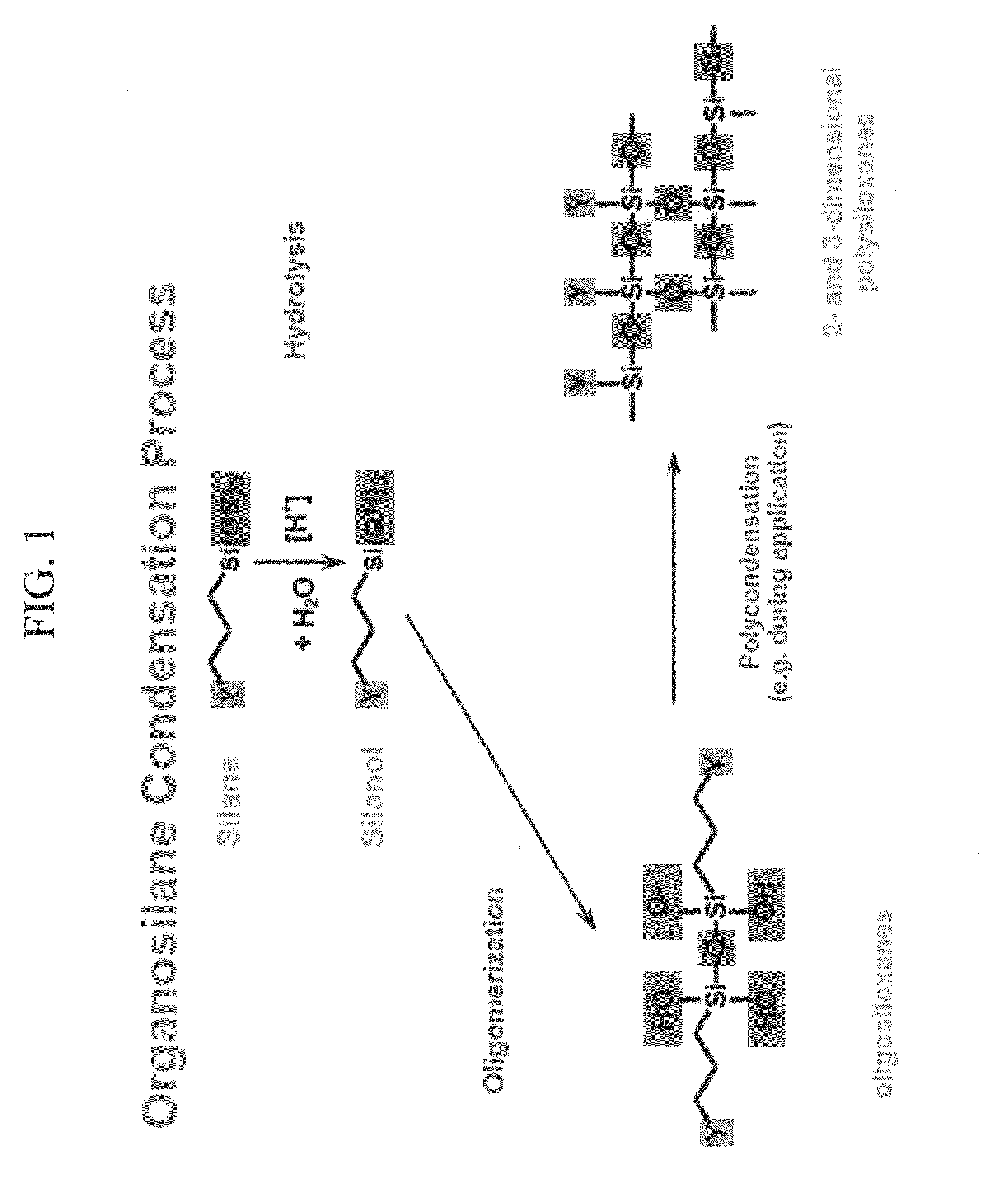

Method used

Image

Examples

example 1

[0080]3 kg HS-1 is mixed with 97 kg water in a reactor. 100 g BYK 348 (BYK-Altana) is added to the mixture.

[0081]A steel sheet (cold-rolled milling) is dipped into the mixture for 2 minutes. The coating is dried with forced air at 60° C. for 5 minutes.

example 2

[0082]1 kg HS-2 is mixed with 20 kg water in a reactor. An aluminum sheet is coated using a squeegee (4 μm) and dried with forced air at 60° C.

example 3

[0083]15 kg HS-2 is mixed with 300 kg water in a reactor. A cold-milled steel sheet is dipped into the mixture and the rendered coating is dried with forced air at 60° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com