Single-component polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof, one-component technology, applied in the direction of coating, can solve the problems of difficult to guarantee the construction quality of two-component polyurethane waterproof coatings, and the one-component polyurethane cannot be decorated externally, and achieves good adhesion and low temperature flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

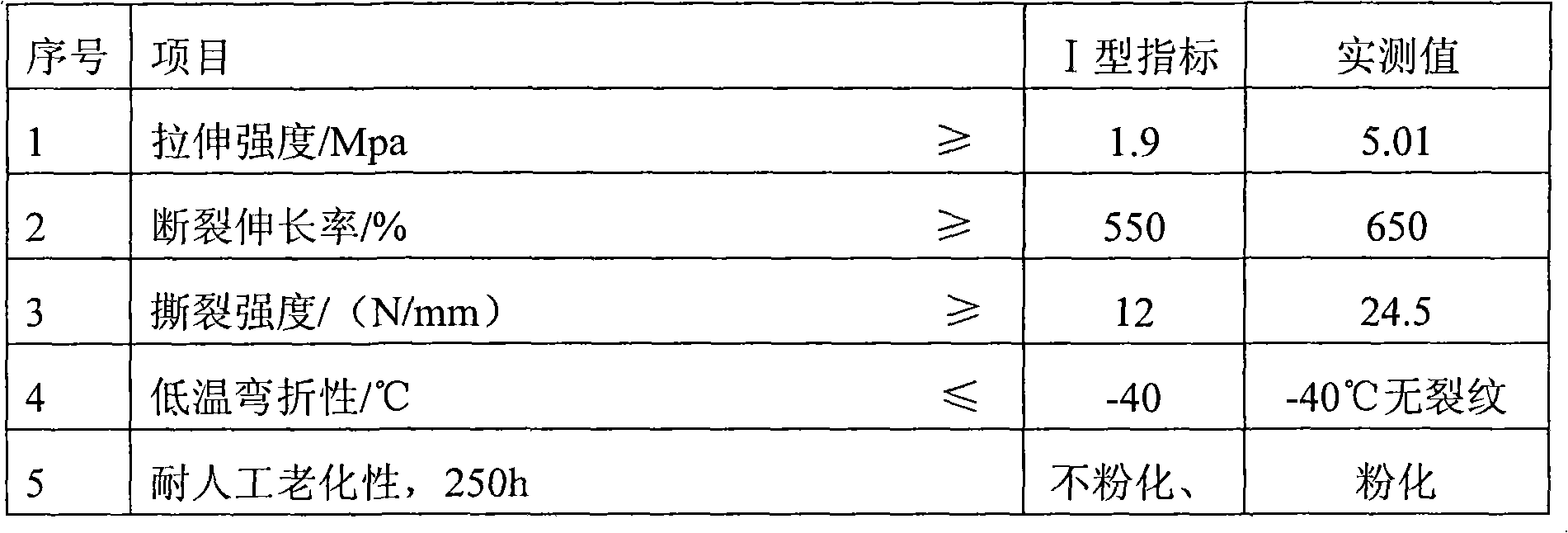

Embodiment 1

[0037] Embodiment 1: (by weight)

[0038] 150 parts of polyether polyol (including 4 parts of polyether polyol 2000, 1 part of polyether polyol 3050, 70 parts of chlorinated paraffin, 35 parts of pigment (R-902+rutile titanium dioxide from DuPont in the United States), 310 parts of filler , 35 parts of toluene diisocyanate (TDI), 15 parts of curing agent, 71.2 parts of xylene, and 2.5 parts of catalyst.

[0039] Preparation method: start after heating polyether polyol and chlorinated paraffin to 110-130°C. Slowly add pigments and fillers, and after stirring, carry out vacuum dehydration and dehydration at 110°C to 120°C at -0.088 to -0.09MPa for 2 hours. After cooling down to 75°C, add 2 / 3 xylene, and then add toluene diisocyanate. (TDI) After stirring and reacting for 2 hours at normal pressure and temperature of 80°C to 85°C, add catalyst and curing agent at 100°C to 110°C for 1.5 hours of heat preservation reaction, after cooling down to 70°C to 80°C, add the remaining met...

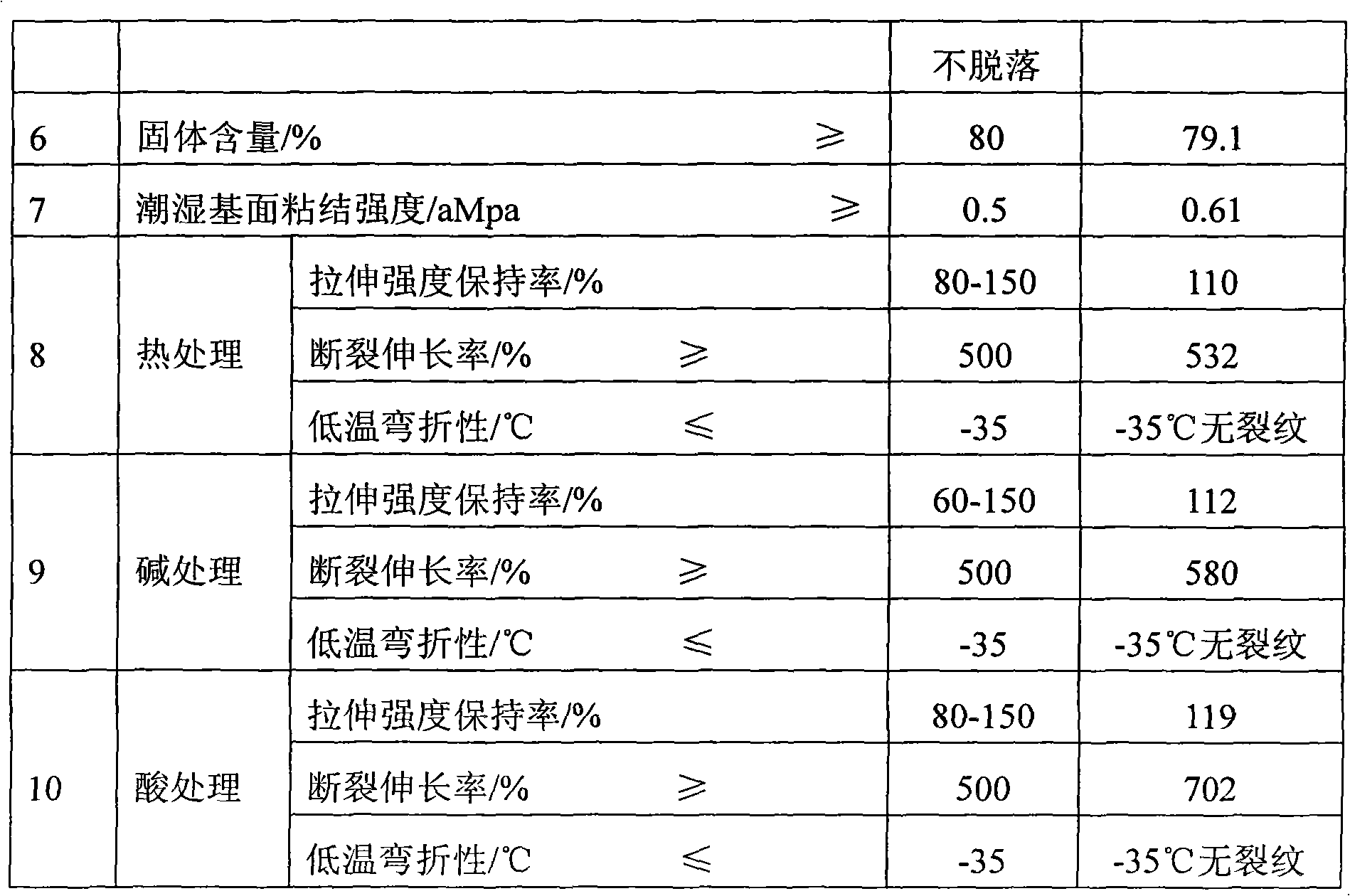

Embodiment 2

[0045] Embodiment 2: (by weight)

[0046] 160 parts of polyether polyol (including 4 parts of polyether polyol 2000, 1 part of polyether polyol 3050, 65 parts of chlorinated paraffin, 35 parts of pigment (R-902+rutile titanium dioxide from DuPont in the United States), 314.5 parts of filler , 32.5 parts of toluene diisocyanate (TDI), 17.5 parts of curing agent, 61.5 parts of xylene, and 3 parts of catalyst.

[0047]Preparation method: After heating polyether polyol and chlorinated paraffin to 110-130°C, slowly add pigments and fillers, and then carry out vacuum dehydration after stirring, and vacuum-0.088--0.09MPa dehydration at 110°C-120°C After 2 hours, when the temperature is lowered to 75°C, add 2 / 3 xylene, then add toluene diisocyanate (TDI), stir and react for 2 hours at normal pressure and 80°C to 85°C, then add catalyst and curing agent at 100°C- Heat the reaction at 110°C for 1.5h. After cooling down to 70°C-80°C, add the remaining metered xylene and catalyst, stir f...

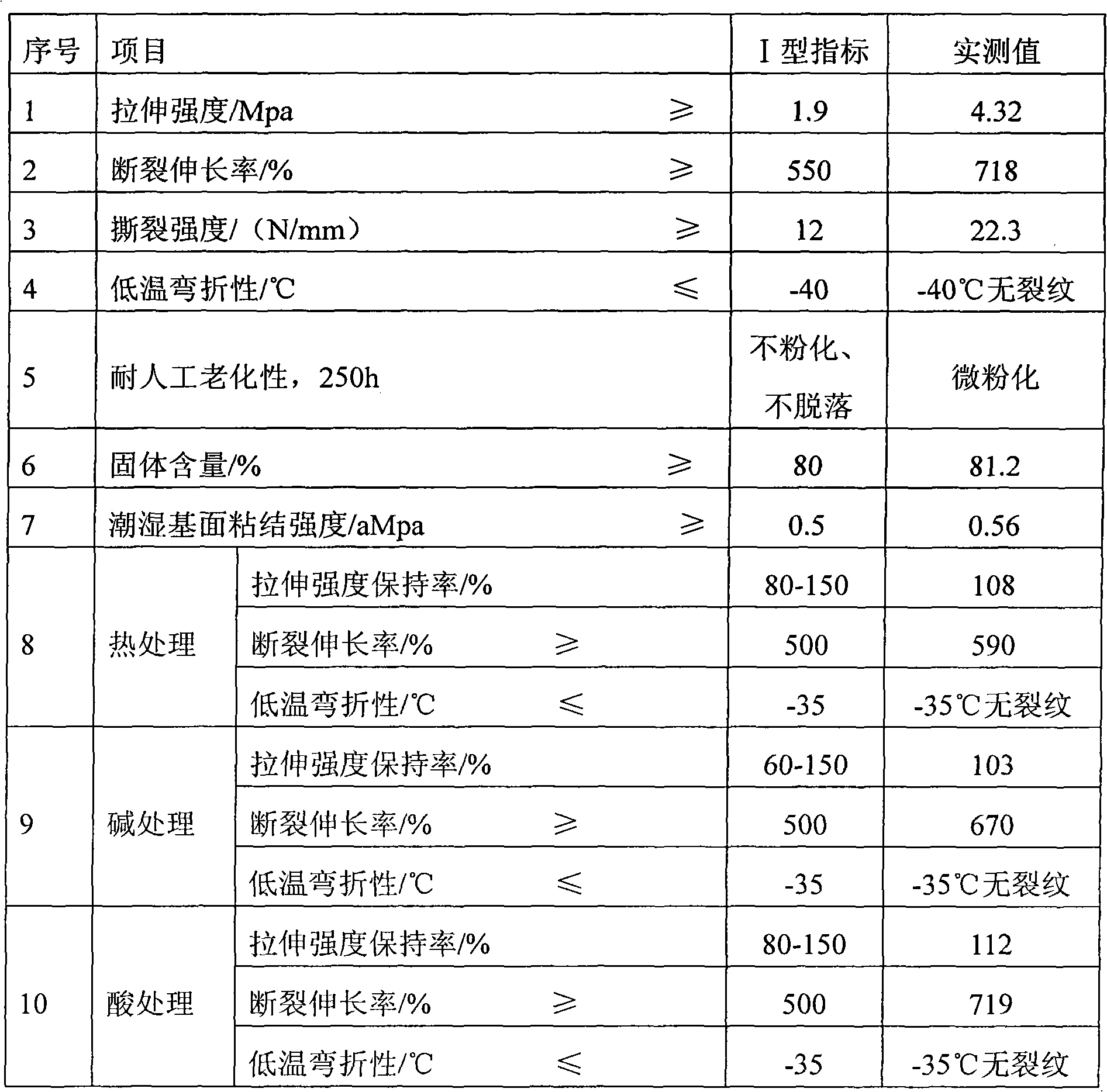

Embodiment 3

[0052] Embodiment 3 (by weight)

[0053] 175 parts of polyether polyol (including 4 parts of polyether polyol 2000, 1 part of polyether polyol 3050, 60 parts of chlorinated paraffin, 35 parts of pigment (R-902+rutile titanium dioxide from DuPont in the United States), 319 parts of filler , 30 parts of toluene diisocyanate (TDI), 20 parts of curing agent, 56.5 parts of xylene, and 3.5 parts of catalyst.

[0054] Preparation method: After heating polyether polyol and chlorinated paraffin to 110-130°C, slowly add pigments and fillers, and then carry out vacuum dehydration after stirring, and vacuum-0.088--0.09MPa dehydration at 110°C-120°C After 2 hours, when the temperature is lowered to 75°C, add 2 / 3 xylene, then add toluene diisocyanate (TDI), stir and react for 2 hours at normal pressure and 80°C to 85°C, then add catalyst and curing agent at 100°C- Heat the reaction at 110°C for 1.5h. After cooling down to 70°C-80°C, add the remaining metered xylene and catalyst, stir for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com