Electroconductive polymer printing ink and preparation method thereof

A conductive polymer, printing ink technology, applied in printing, ink, printing devices, etc., can solve the problems of large ink film thickness, environmental pollution, low printing accuracy, etc., and achieve thin ink film thickness, good conductivity, and printing accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

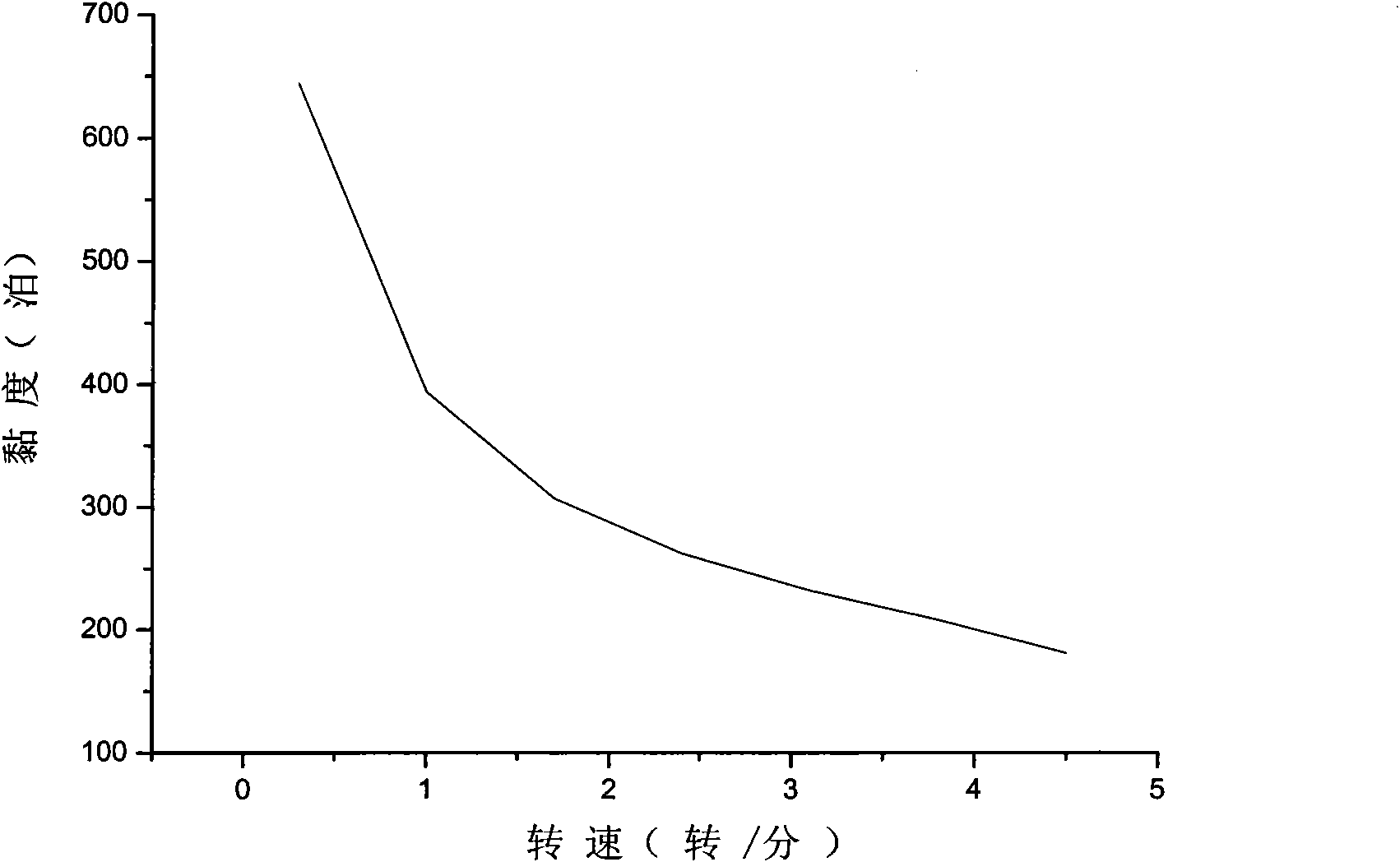

[0029] The first embodiment: take by weighing 60.0% of the conductive polymer aqueous dispersion based on polyethylenedioxythiophene, and account for 5.0% of the conductive polymer aqueous dispersion based on polyethylenedioxythiophene. Mix sulfone with it to improve conductivity; weigh 30.0% of water-based polyurethane resin, and add water-based thickener accounting for 4% of water-based polyurethane resin to mix with it, and grind it with a three-roll mill for 10min to mix evenly; add 0.8% of N,N-Dimethylethanolamine adjusts the pH of the mixed solution of the conductive polymer and dimethyl sulfoxide to 8.5-9, and then mixes it with the thickened water-based polyurethane resin; then adds 5.0% glycerol and a certain amount Antifoaming agent, leveling agent and other ink additives, after uniform dispersion, the required conductive ink can be obtained (the above percentages are all volume fractions). The above-mentioned water-based thickeners include any one or a combination o...

no. 2 example

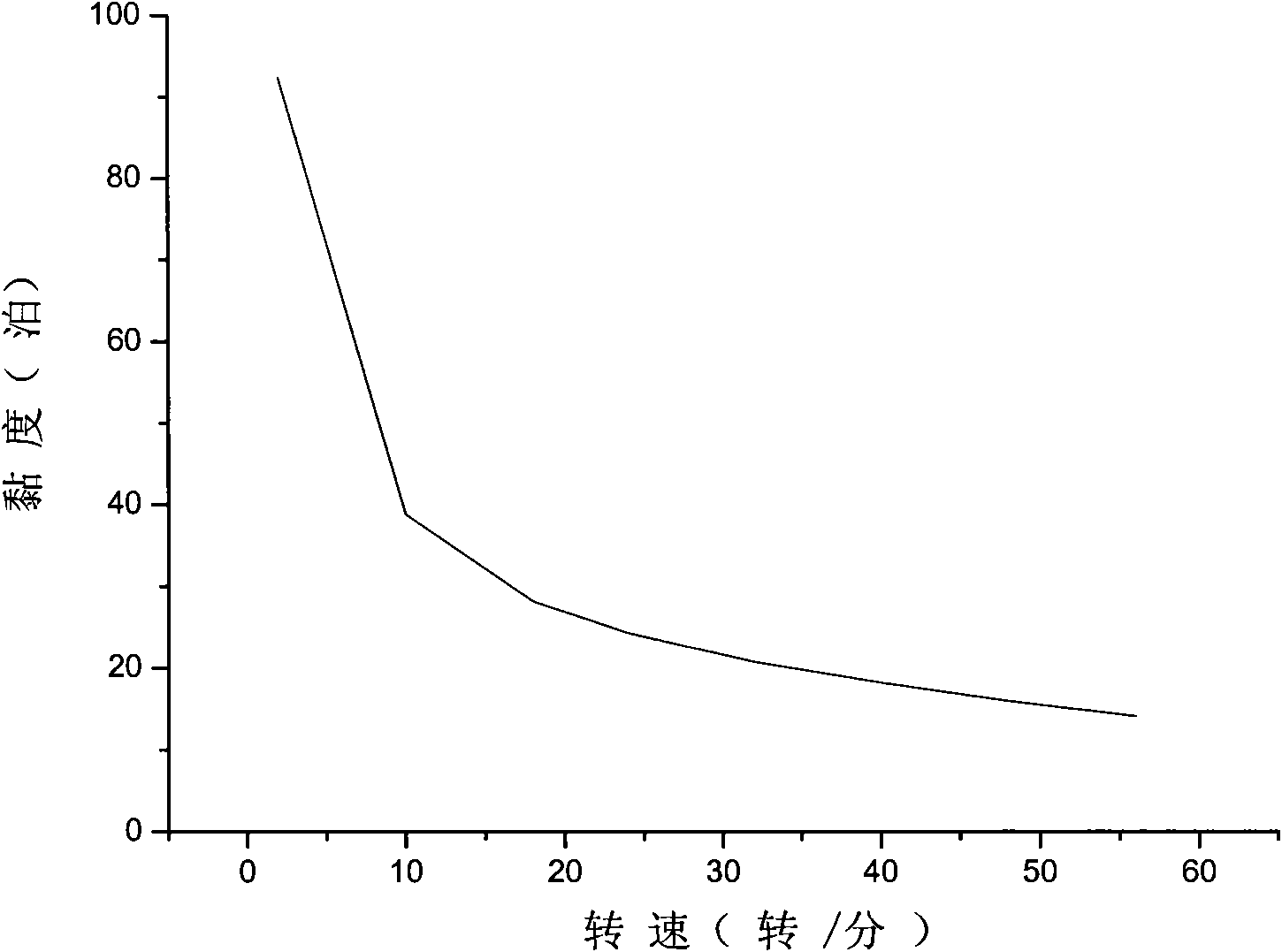

[0035]The second embodiment: take by weighing 71.7% of the conductive polymer aqueous dispersion based on polyethylenedioxythiophene, and account for 5.0% of the conductive polymer aqueous dispersion based on polyethylenedioxythiophene. Mix sulfone with it to improve conductivity; weigh 17.9% of water-based polyurethane resin, and add water-based thickener accounting for 8% of water-based polyurethane resin to mix with it, and grind it with a three-roll mill for 10min to mix evenly; 0.8% of N , N-dimethylethanolamine adjusts the pH of the mixed solution of the conductive polymer and dimethyl sulfoxide to be 8.5 to 9, and then mixes it with the thickened water-based polyurethane resin; then adds 5.0% glycerol and a certain amount of Ink additives such as defoamers and leveling agents can be uniformly dispersed to obtain the required conductive ink (the above percentages are all volume fractions). The above-mentioned water-based thickeners include any one or a combination of two...

no. 3 example

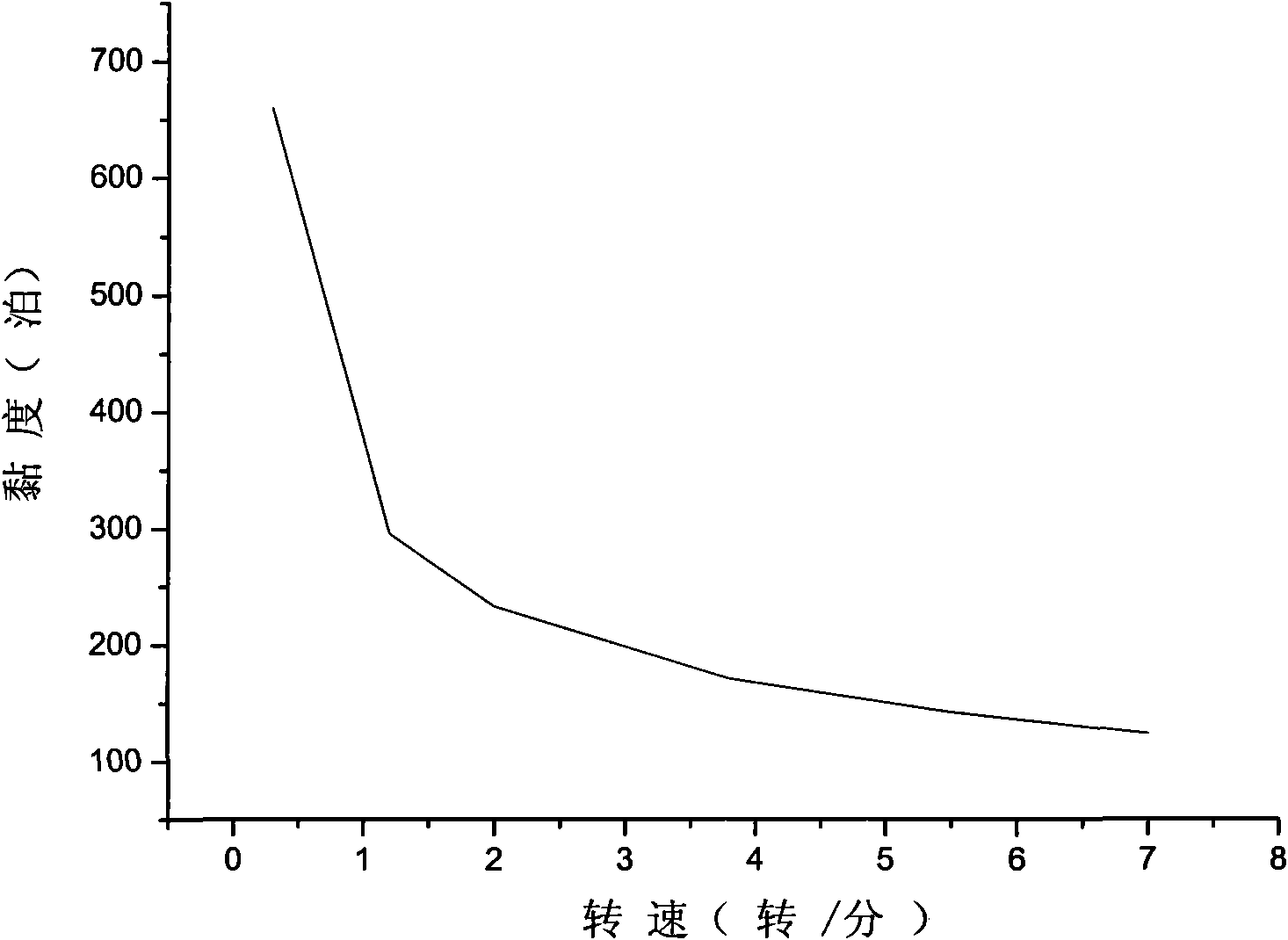

[0040] The third embodiment: take by weighing 66.6% of the conductive polymer aqueous dispersion based on polyethylenedioxythiophene, and account for 5.0% of the conductive polymer aqueous dispersion based on polyethylenedioxythiophene. Mix sulfone with it to improve conductivity; weigh 22.2% of water-based polyurethane resin, and add water-based thickener accounting for 8% of water-based polyurethane resin to mix with it, and grind it with a three-roll mill for 10min to mix evenly; 0.8% of N , N-dimethylethanolamine adjusts the pH of the mixed solution of the conductive polymer and dimethyl sulfoxide to be 8.5 to 9, and then mixes it with the thickened water-based polyurethane resin; then adds 5.0% glycerol and a certain amount of Ink additives such as defoamers and leveling agents can be uniformly dispersed to obtain the required conductive ink (the above percentages are all volume fractions). The above-mentioned water-based thickeners include any one or a combination of two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com