Mixed solvent for removing acid gas

A technology of mixed solvents and acid gases, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high equipment material requirements, complex processes, and high cold preservation requirements, and achieve optimized formulas, reduced energy consumption, and low The effect of fees

Inactive Publication Date: 2012-09-12

CHINA PETROLEUM & CHEM CORP +1

View PDF2 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It has the characteristics of strong absorption capacity, good selectivity, high degree of purification, and low regeneration energy consumption, but it has strong toxicity, high requirements for equipment materials, high requirements for cold preservation, complex processes, and the need to pay high foreign patent technology fees and proprietary equipment, etc. shortcoming

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

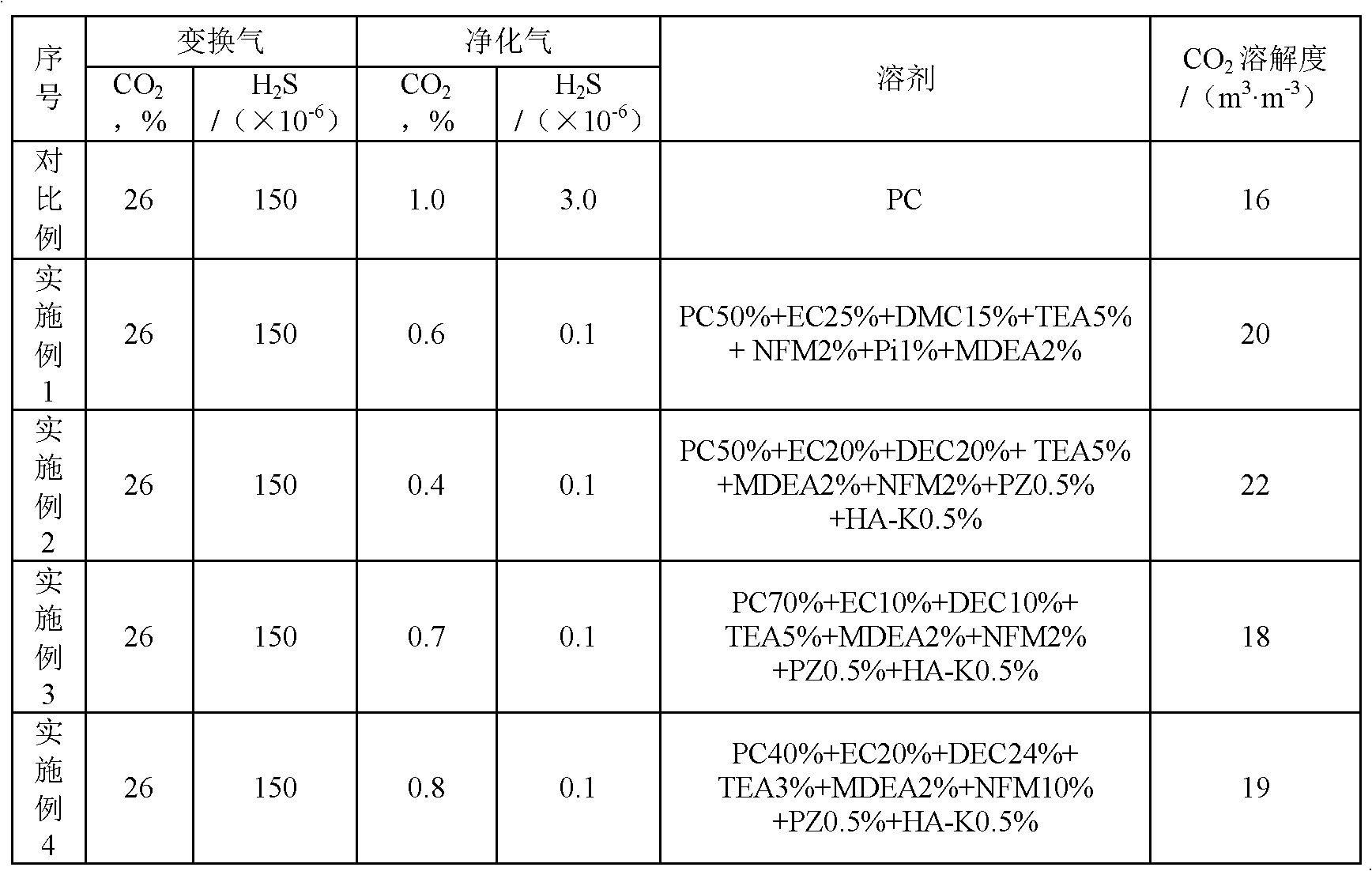

Embodiment 1

[0025] Mixed solvent PC50%+EC25%+DMC15%+TEA5%+NFM2%+Pi1%+MDEA2%

Embodiment 2

[0027] Mixed solvent PC50%+EC20%+DEC20%+TEA5%+MDEA2%+NFM2%+PZ0.5%+HA-K0.5%

Embodiment 3

[0029] Mixed solvent PC70%+EC10%+DEC10%+TEA5%+MDEA2%+NFM2%+PZ0.5%+HA-K0.5%

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a mixed solvent for removing acid gas, which belongs to the technical field of gas separation and is characterized by being composed of two or more than two of main absorption components, assisting absorption components and active components in mixing mode, wherein the main absorption components comprise propylene carbonate (PC), ethylene carbonate (EC), dimethyl carbonate (DMC), diethyl carbonate (DEC) and N-methyl-2-pyrrolidone (NMP), the assisting absorption components comprise N-methyldiethanolamine (MDEA), triethanolamine (TEA), diglycolamine (DGA) and dimethylethanolamine (DMEA), and the active components comprise phosphoric acid (Pi), piperazine (PZ), urotropin (HA-K), N-Formylmorpholine formylmorpholine (NFM), 2-amino-2methyl-1-propyl alcohol (AMP) and morpholine by-products. By means of the mixed solvent for removing acid gas, on one hand, absorption capacity and purification of CO2 are improved, and on the other hand, desulfuration accuracy is greatly improved.

Description

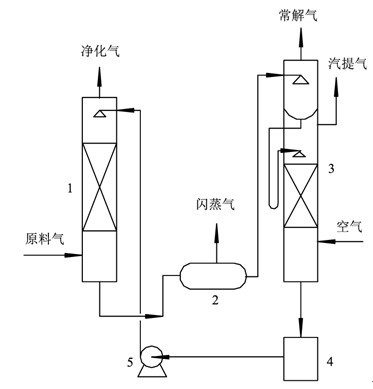

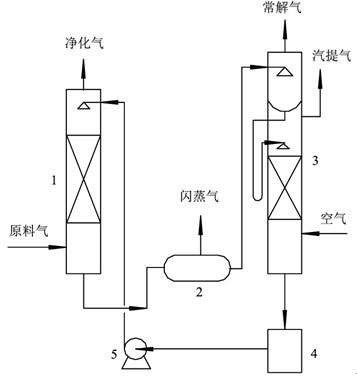

technical field [0001] The invention belongs to the field of gas separation, and relates to a mixed solvent for removing acid gas (CO2, sulfide) from medium and high pressure process gas. Background technique [0002] In petrochemical, coal chemical, ammonia synthesis, methanol synthesis, oxo synthesis, hydrogen production and natural gas industries, it is necessary to remove acid gases (mainly carbon dioxide and sulfide) from raw gas to meet the needs of subsequent processes. At present, there are many mature purification methods in the industry, which can be divided into three types: physical absorption, chemical absorption, and physical and chemical absorption. The solvents used are pure physical solvent absorbents, chemical solvents and activators. Absorbents composed of solvents. Generally speaking, the investment and operation costs of the physical absorption method are low, and it is not necessary to use steam regeneration, and it is not necessary to install a large ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/14

Inventor 梁锋施小红明素荣徐丙根张弛

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com