Aqueous polyurethane matting resin

A water-based polyurethane and matting resin technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as uneven mixing, affecting decorative effects, and coating gloss differences, and achieve consistent surface tension, good environmental protection, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This example includes the following components in parts by weight: 14 parts of diisocyanate, 1 part of dimethylol propionic acid (DMPA), 43 parts of glycol, 0.06 parts of organic bismuth catalyst, 0.8 part of dimethylethanolamine, 2 -1 part of sodium [(2-aminoethyl)amino]ethanesulfonate, 0.8 parts of hydrazine hydrate, 8 parts of N-methylpyrrolidone solvent, and 104 parts of deionized water.

[0017] In this embodiment, hydrogenated phenylmethane diisocyanate is selected as the diisocyanate; 15 parts of polyoxypropylene diol and 28 parts of polycarbonate diol are selected as the diol.

Embodiment 2

[0019] This example includes the following components in parts by weight: 15 parts of diisocyanate, 1 part of dimethylolpropionic acid (DMPA), 50 parts of diol, 0.05 parts of organic bismuth catalyst, 0.8 part of dimethylolamine, 2 -1 part of sodium [(2-aminoethyl)amino]ethanesulfonate, 0.8 parts of hydrazine hydrate, 8 parts of N-methylpyrrolidone solvent, and 122 parts of deionized water.

[0020] In this embodiment, 8 parts of hydrogenated phenylmethane diisocyanate and 6 parts of isophorone diisocyanate are selected as diisocyanate; 20 parts of polycarbonate diol and 30 parts of polyε-caprolactone diol are selected as diol.

Embodiment 3

[0022] The present embodiment includes the following components in parts by weight: 15 parts of diisocyanate, 1 part of dimethylol propionic acid (DMPA), 54 parts of glycol, 0.05 parts of organic bismuth catalyst, and 1 part of dimethylolamine , 1 part of sodium 2-[(2-aminoethyl)amino]ethanesulfonate, 5 parts of hydrazine hydrate, 7 parts of N-methylpyrrolidone solvent, and 132 parts of deionized water.

[0023] In this embodiment, the diisocyanate is selected from isophorone diisocyanate; the diol is selected from polyε-caprolactone diol.

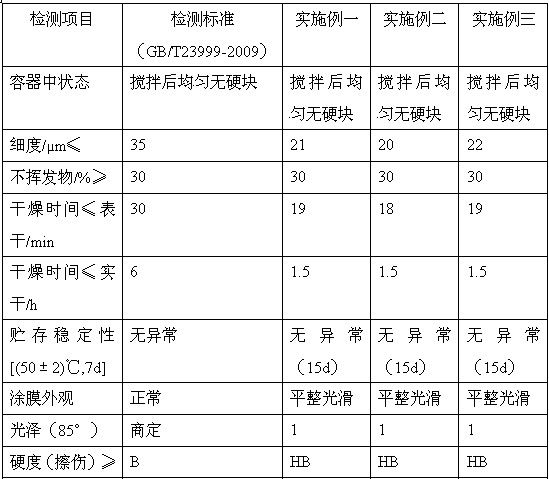

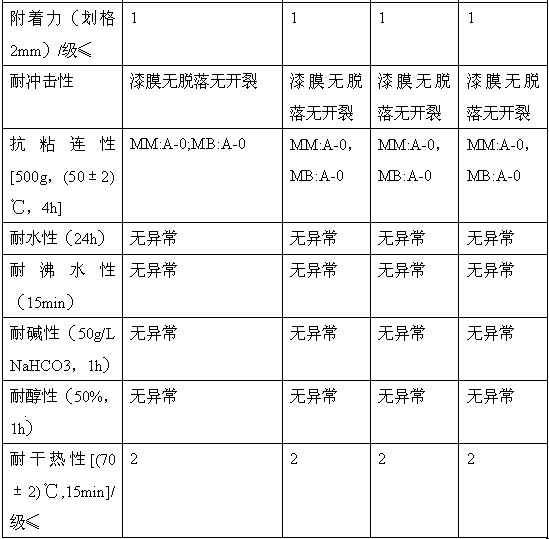

[0024] The products obtained in the above examples are tested according to the national standard (GB / T23999-2009), and reach the following indicators:

[0025]

[0026]

[0027] It can be seen through testing that the water-based polyurethane matting resin provided by the present invention has uniform coating, good matting effect, ideal weather resistance and corrosion resistance, and long service life. The product obtained in Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com