Aqueous ink

A technology of water-based inks and water-based pigments, applied in inks, household appliances, applications, etc., to achieve the effects of excellent printing adaptability, excellent gloss, and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

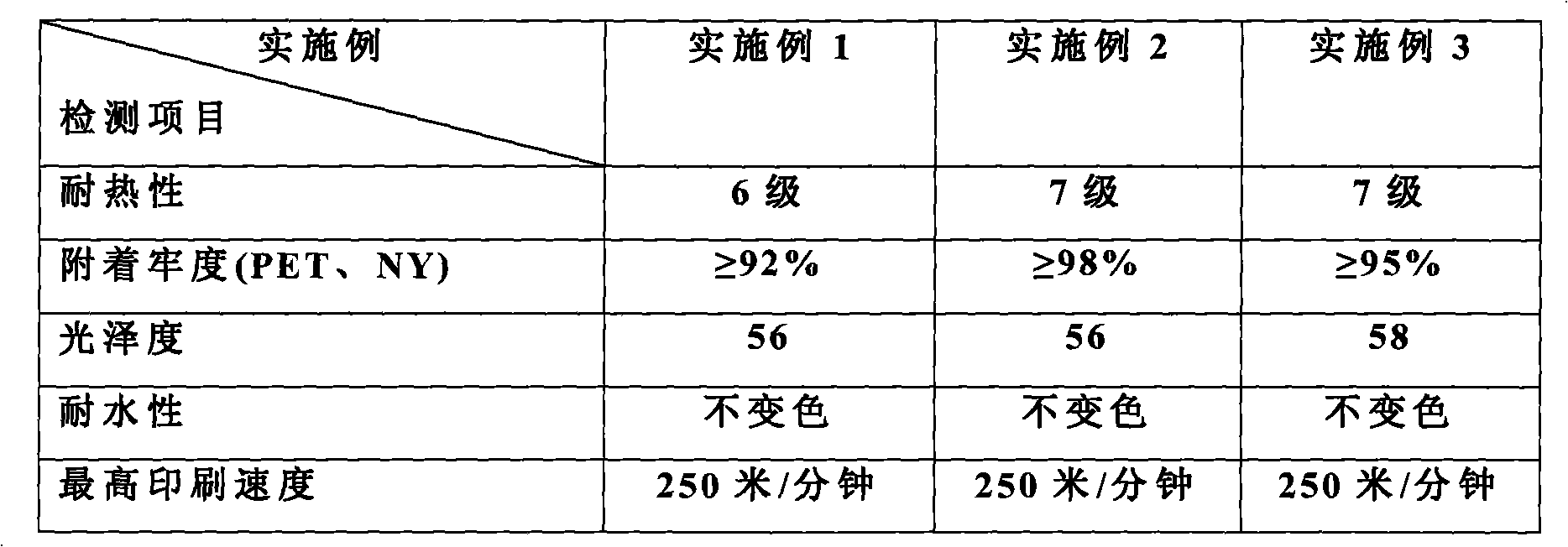

Examples

Embodiment 1

[0015] A kind of water-based ink, this water-based ink is made up of the component of following weight ratio: 30 parts of water-based polyurethane resins (number-average molecular weight 100,000), 35 parts of water-based magenta pigments, 3.8 parts of propylene glycol, 1.2 parts of dimethylethanolamine and water 30 servings.

[0016] The above water-based ink is prepared by the following method: add water-based polyurethane resin, propylene glycol, dimethylethanolamine, and water into the mixing tank in proportion, add water-based magenta pigment while stirring, stir on a high-speed mixer for 15-30 minutes, and then sand Disperse in a mill, and the ink product will be obtained when the fineness reaches below 5 microns.

Embodiment 2

[0018] A kind of water-based ink, this water-based ink is made up of the component of following weight ratio: 30 parts of water-based polyurethane resins (number average molecular weight 150,000), 30 parts of water-based yellow pigments, 3.8 parts of propylene glycol, 1.2 parts of dimethylethanolamine and 35 parts of water share.

[0019] The aqueous ink of the present embodiment can be prepared according to the method identical with embodiment.

Embodiment 3

[0021] A water-based ink, the water-based ink is composed of the following components by weight: 35 parts of water-based polyurethane resin (100,000 number average molecular weight), 30 parts of water-based phthalocyanine blue pigment, 3 parts of propylene glycol, 1.2 parts of dimethylethanolamine, 0.8 parts of fungicide and 30 parts of water.

[0022] The aqueous ink of the present embodiment can be prepared according to the method identical with embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com