Water-based automobile finish and preparation method thereof

A kind of automotive topcoat, water-based technology, applied in the direction of coating, etc., can solve problems such as poor gloss, poor sun protection and anti-aging performance, and poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

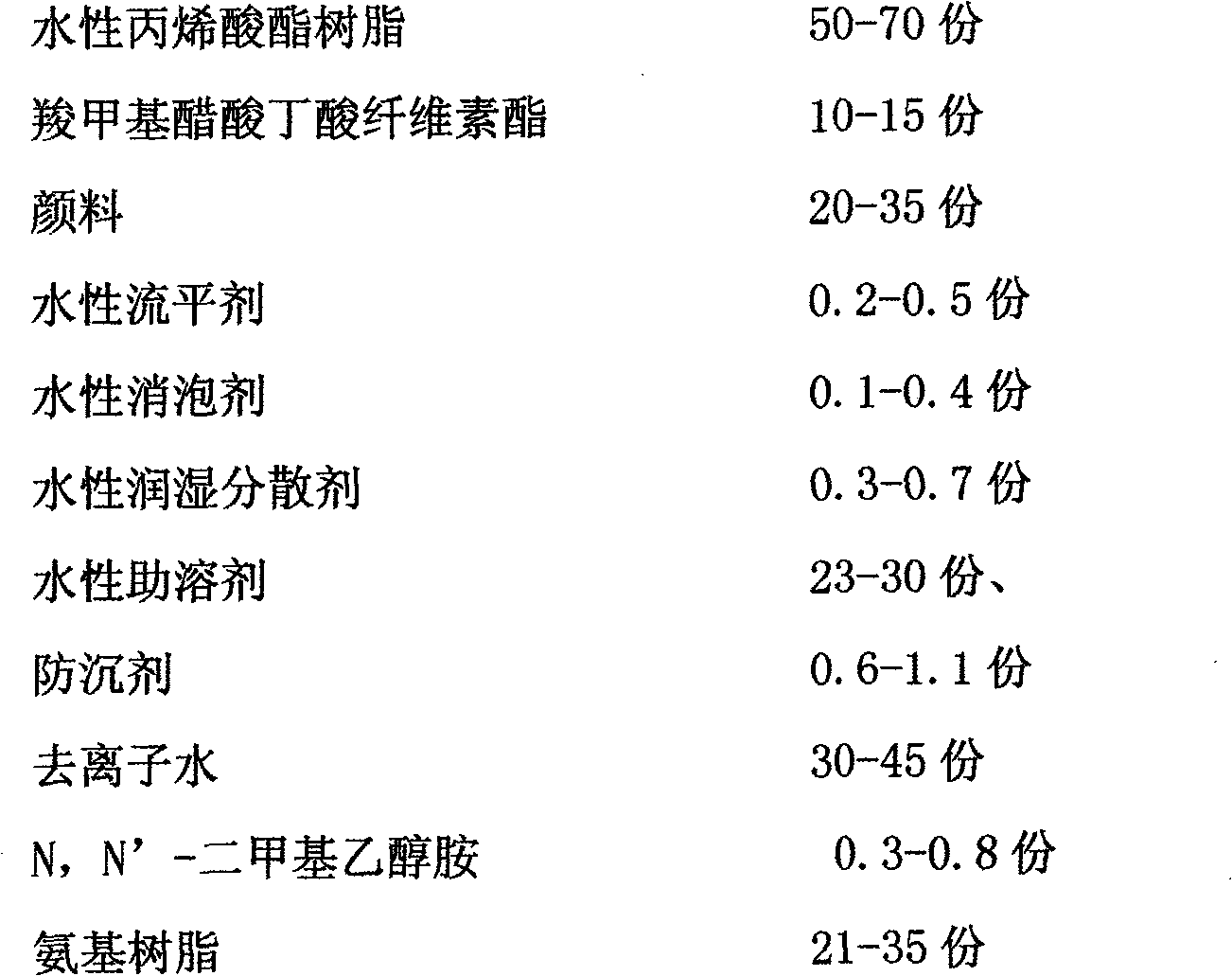

Method used

Image

Examples

Embodiment 1

[0019] 25g methyl methacrylate, 8g hydroxyethyl methacrylate, 12g styrene, 3g benzyl methacrylate, 8g acrylic acid, 12g triethoxyvinylsilane, 1g octylphenol polyoxyethylene ether (OP-10) and 1.5g of sodium lauryl sulfate were pre-emulsified by a high-speed stirrer at room temperature to prepare a pre-emulsion.

[0020] Add 100ml of propylene glycol methyl ether and 50ml of isopropanol into a four-necked flask equipped with an electric stirrer, a condenser, and a nitrogen inlet tube, then raise the temperature to 80°C, and add dropwise 0.5g of sodium bicarbonate and 0.6g of potassium persulfate , 120g of deionized water, 0.8g of dodecyl mercaptan and 50.5g of pre-emulsion were added within 1.5h, and after the dropwise addition was completed, the reaction was continued for 2h. Then, add 20g of pre-emulsion and 0.2g of potassium persulfate, and finish adding within 0.5h. After the dropwise addition, raise the temperature to 80°C, continue stirring for 3h, cool down to 40°C, add 8...

Embodiment 2

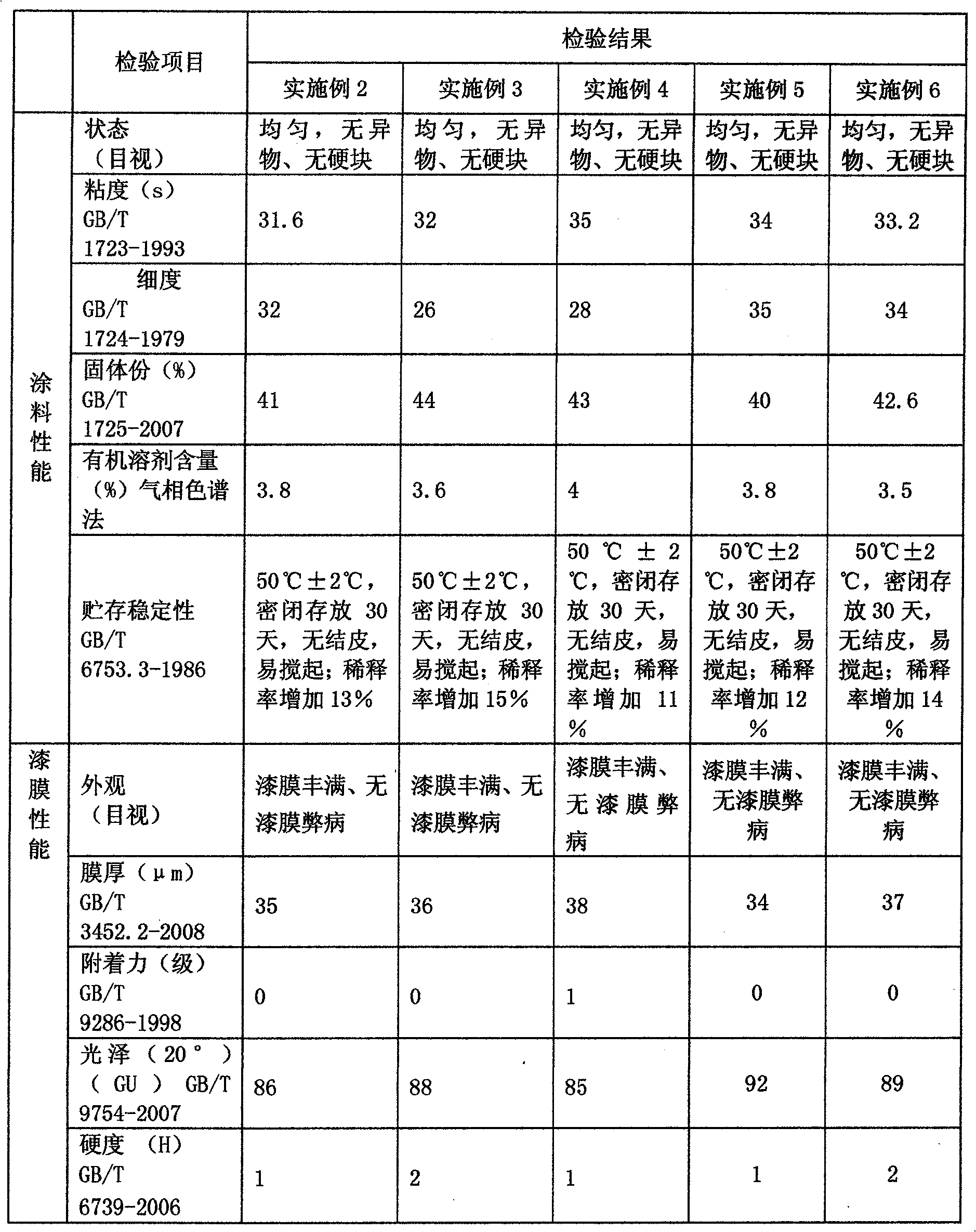

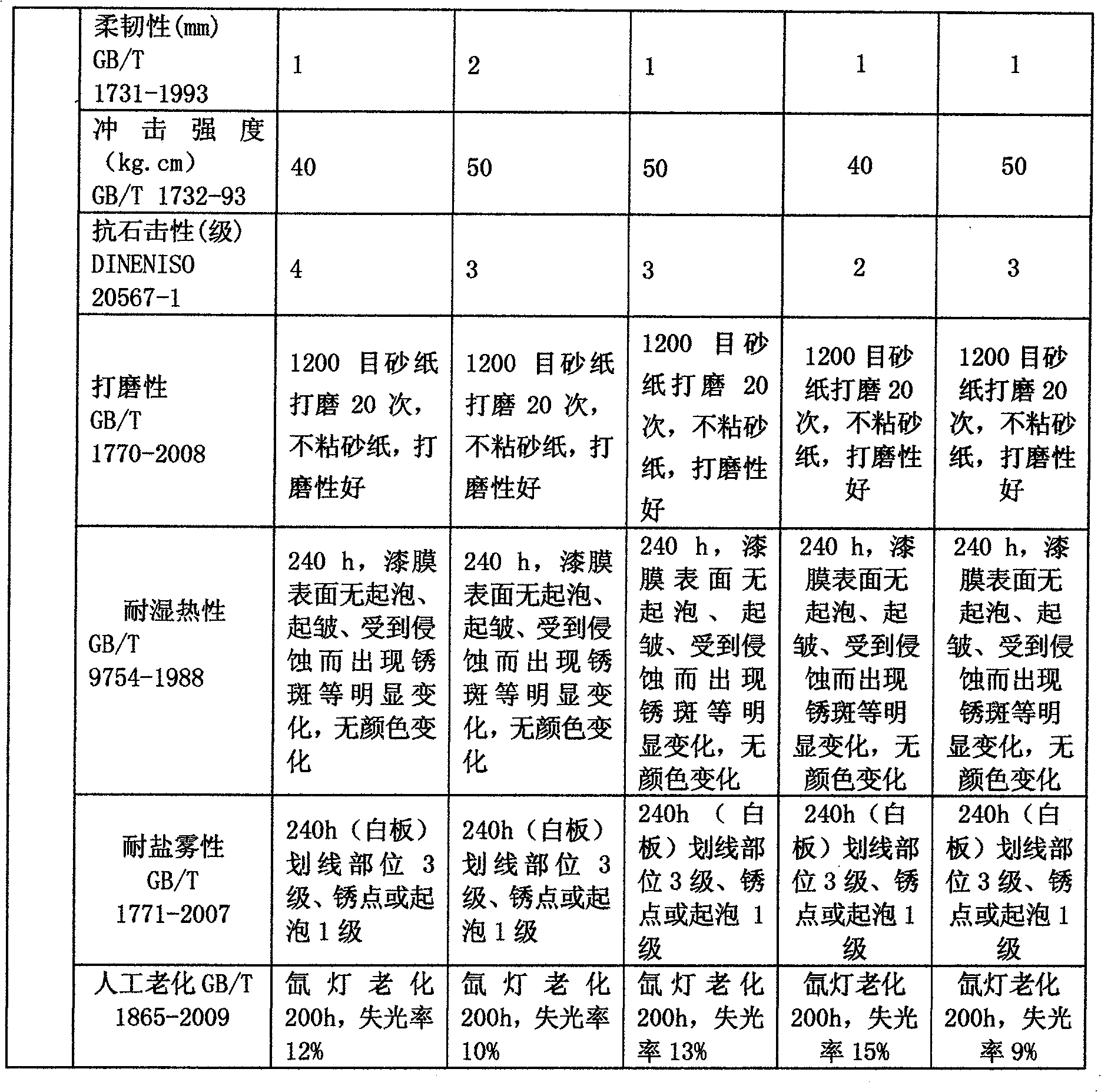

[0022] The waterborne acrylic ester resin that 50g embodiment 1 obtains, 10g carboxymethyl cellulose acetate butyrate, 20g titanium dioxide, 23g Virahol, 0.3g N, N'-dimethylethanolamine, 30g deionized water, Add 0.3g of DISPERBYK-180 and 0.1g of BYK011 into the high-speed disperser, and stir for 4 hours at a speed of 1200rpm. Then, 0.2 g of BYK333, 0.6 g of BYK420, and 21 g of Cymel 303 were added, and stirred at a speed of 2500 rpm for 5 h. Then, filter with a 200-mesh filter screen to obtain an automotive water-based finish paint. The topcoat was sprayed on the sample plate coated with primer and intermediate paint, and baked at 140°C for 20min to test the performance of the paint film. The performance of automotive water-based topcoat paint and the test results of paint film are shown in Table 1.

Embodiment 3

[0024] The aqueous acrylic ester resin that 70g embodiment 1 obtains, 15g carboxymethyl cellulose acetate butyrate, 35g carbon black, 30g ethylene glycol methyl ether, 0.8g N, N'-dimethylethanolamine, 45g Add ionized water, 0.7g of DISPERBYK-184, and 0.4g of BYK012 into the high-speed disperser, and stir for 2 hours at a speed of 1600rpm. Then, 0.5g of BYK380, 1.1g of water-based bentonite, and 35g of Cymel 325 were added, and stirred at a speed of 1800rpm for 7h. Then, filter with a 200-mesh filter screen to obtain an automotive water-based finish paint. The topcoat was sprayed on the sample plate coated with primer and intermediate paint, and baked at 140°C for 20min to test the performance of the paint film. The performance of automotive water-based topcoat paint and the test results of paint film are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com