Water-based graphene/carbon nanotube composite electric-heating conversion printing ink and preparation method thereof

A technology of carbon nanotube composite and water-based graphene, which is applied in ink, household utensils, applications, etc., can solve problems such as difficult to increase solid content, resin curing failure, and water content increase, so as to improve factory safety and improve electrical conductivity uniformity Sexuality, the effect of improving product quality rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

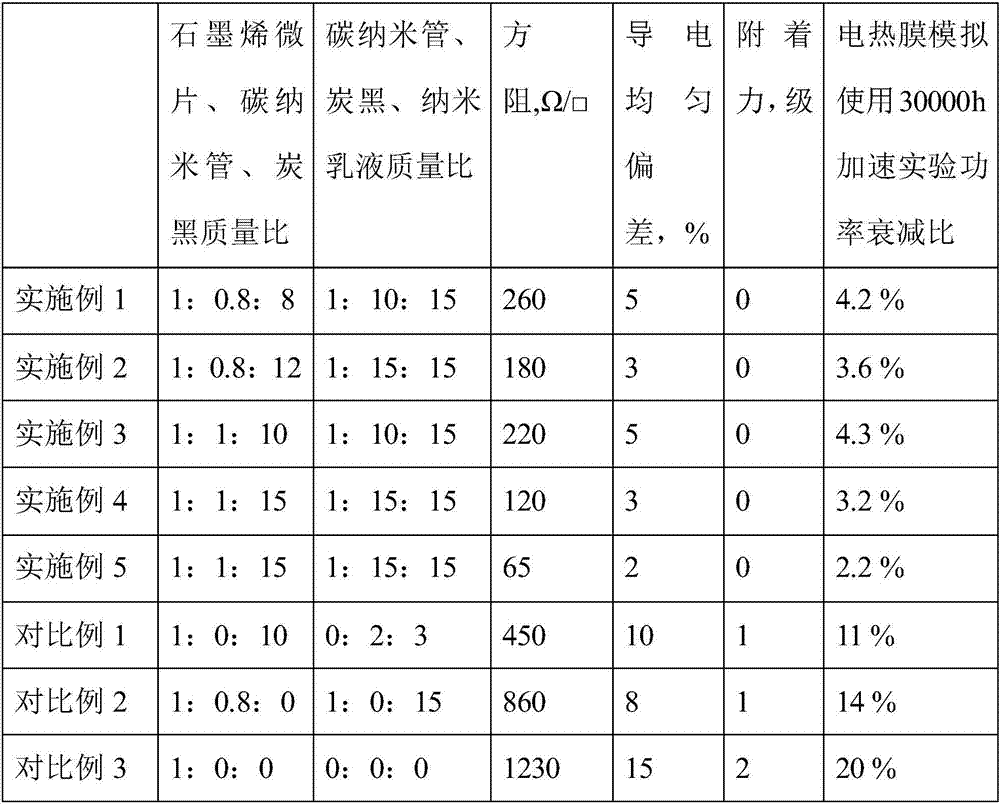

Embodiment 1

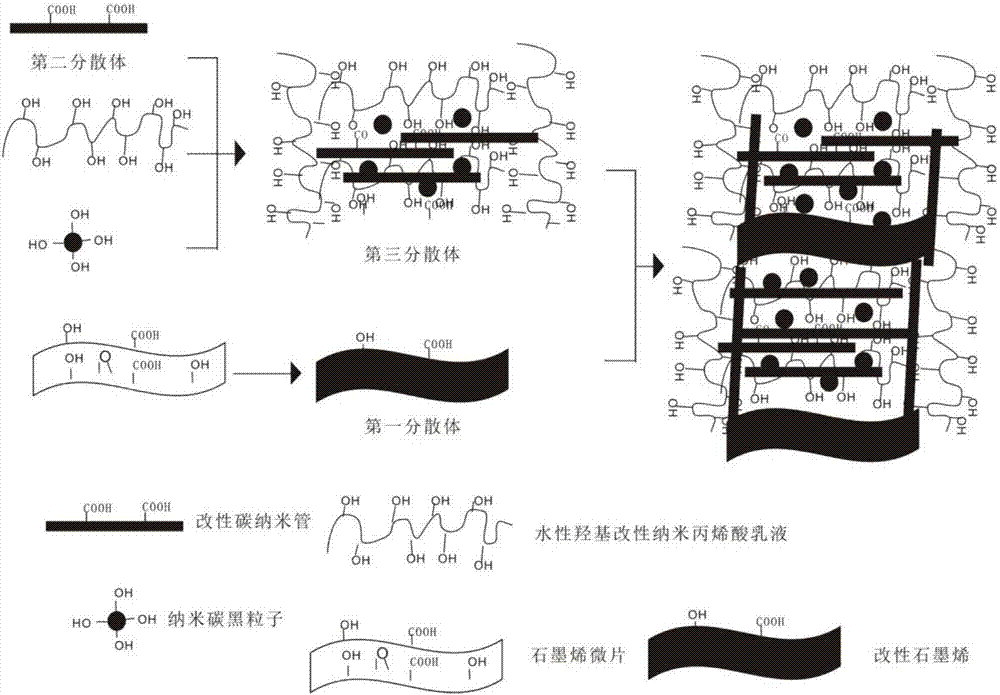

[0055] refer to figure 1 , a preparation method of water-based graphene / carbon nanotube composite electrothermal conversion ink, comprising the steps of:

[0056] S1, by weight 5 parts of graphene microsheets (carbon content greater than 99%, lateral size is 10-20 μm, graphene sheet thickness is 2.0-3.35nm), 1.25 parts of water-based nonionic low-polymerization polymer dispersant , 93.75 parts of water are automatically fed into the 500L stirring tank, the stirring paddle is turned on, the stirring speed is 200rpm, and the stirring time is 20min; The temperature is 25°C; the first dispersion is obtained after the dispersion is completed;

[0057] Wherein the graphene microflakes are one or more of graphene produced by gas phase plasma, graphene flakes produced by arc method, reduced graphene oxide, and graphene nanosheets;

[0058] S2. Put multi-walled carbon nanotubes (with a diameter of 0.1-50nm, an aspect ratio of 0.1-50, and a carbon content greater than 99%) in a strong...

Embodiment 2

[0062] S1, S2, S4 are identical with embodiment 1, and S3 changes into:

[0063] Automatically feed 2 parts of the second dispersion, 30 parts of water-based hydroxyl-modified nano-acrylic emulsion, 0.5 parts of sodium dodecylbenzenesulfonate and 33 parts of ultrapure water into the stirring tank by weight, and turn on the stirring paddle to stir The rotation speed is 200rpm, the stirring time is 20min, then add 30 parts of carbon black powder with a particle size of 50nm, 2 parts of water-based anionic dispersant, 2.5 parts of dimethylethanolamine, turn on the stirring paddle, the stirring speed is 200rpm, and the stirring time is 20min ; Then turn on the high-speed dispersion disc for high-speed dispersion, the dispersion speed is 1200rpm, the dispersion time is 20min, and the ambient temperature during the high-speed dispersion process is 25°C; after the dispersion is completed, filter to obtain the third dispersion.

Embodiment 3

[0065] S1, S2, S3 are identical with embodiment 1, and S4 changes into:

[0066] Mix 20 parts of the first dispersion, 50 parts of the third dispersion, and 30 parts of water-based resin in parts by weight, start stirring, the stirring speed is 200rpm, and the stirring time is 20min, then turn on the high-speed dispersion, the dispersion speed is 1200rpm, and the dispersion time is 20min; then grind until the particle size is 5μm, and the grinding speed is 800rpm; then add 0.2 parts of leveling agent, 0.2 parts of defoamer, 0.2 parts of pH regulator, 0.2 parts of preservative, 0.2 parts of anti-sedimentation agent and stir, and the stirring speed is 200rpm , the stirring time is 20min, and then the high-speed dispersion disc is turned on for high-speed dispersion. The dispersion speed is 1200rpm, the dispersion time is 20min, and the ambient temperature is 25°C during the high-speed dispersion process to obtain water-based graphene / carbon nanotube composite electrothermal conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com