Poly(carbonate-ether) aqueous polyurethane, aqueous polyurethane adhesive and preparation method thereof

A water-based polyurethane and carbonate technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as reducing the use efficiency of water-based polyurethane adhesives, and achieve excellent storage stability, excellent peeling force, The effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

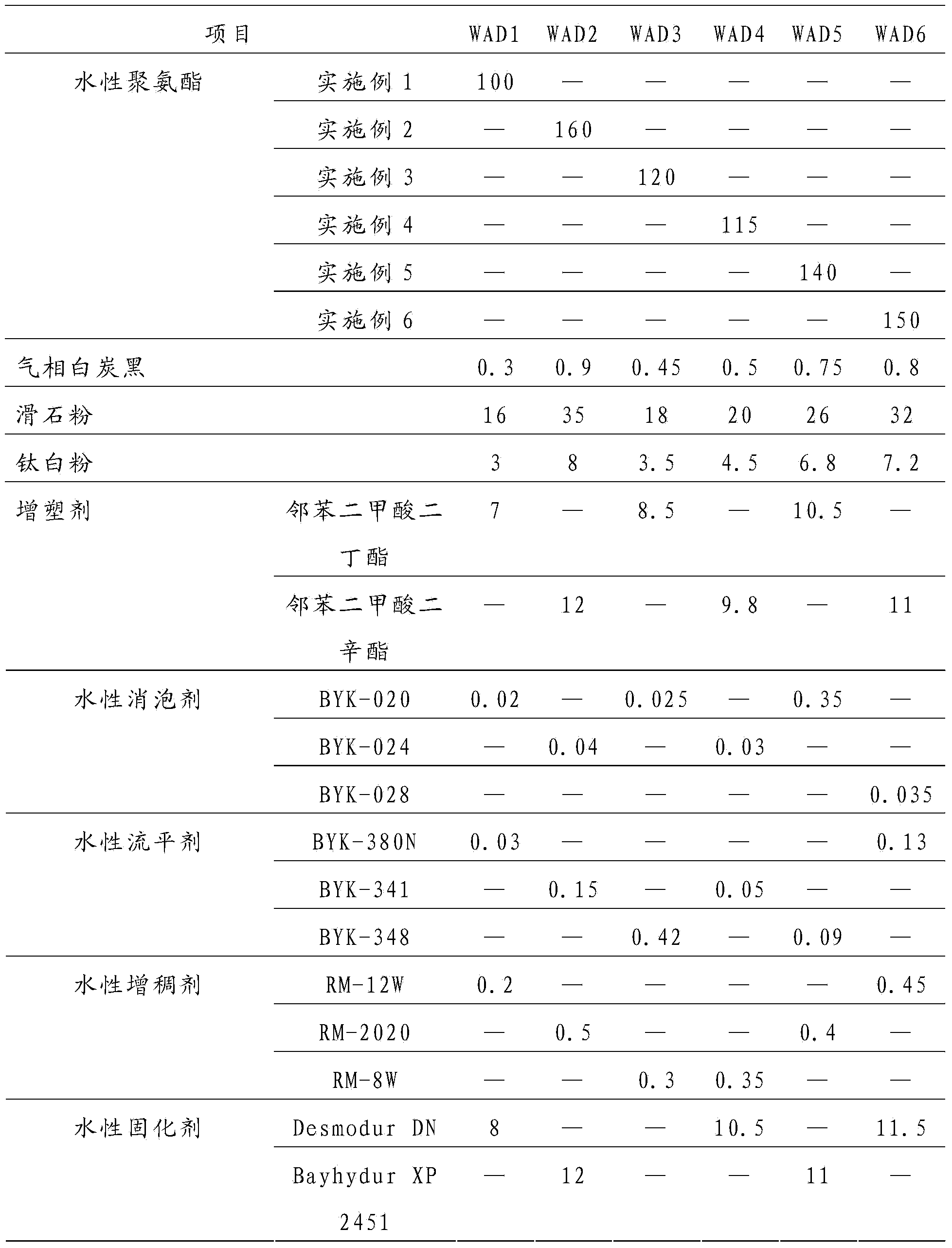

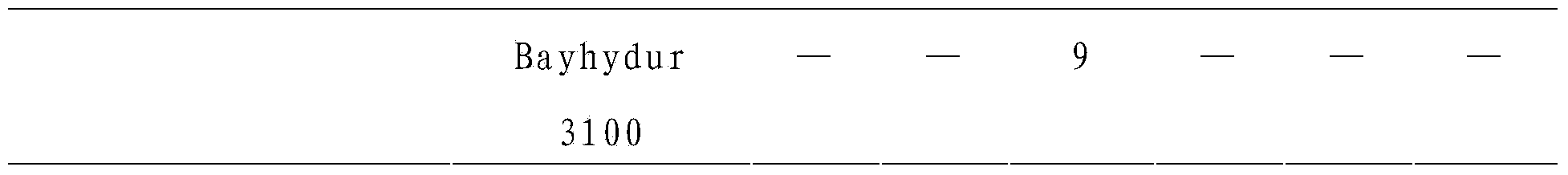

[0066] The invention also discloses a preparation method of water-based polyurethane adhesive, which comprises the following steps:

[0067] 0.2-0.5 parts by weight of water-based thickener, 0.03-0.15 parts by weight of water-based leveling agent, 0.02-0.04 parts by weight of water-based defoamer, 7-12 parts by weight of plasticizer, 16-35 parts by weight of talcum powder, 3-8 parts by weight of titanium dioxide and 0.3-0.9 parts by weight of fumed white carbon black are stirred to obtain the first component;

[0068] Add 8-12 parts by weight of a water-based curing agent into the first component, and stir for 3-5 minutes to obtain a water-based polyurethane adhesive.

[0069] According to the present invention, first poly(carbonate-ether) type water-based polyurethane emulsion, water-based thickener, water-based leveling agent, water-based defoamer, plasticizer, talcum powder, titanium dioxide and fumed silica are stirred and stirred , the rotational speed of the stirring is...

Embodiment 1

[0074] Add 150g of low molecular weight poly(carbonate-ether) glycol (molecular weight: 1500 Daltons) into the three-necked flask, heat to 110°C, dehydrate at -0.98MPa for 1 hour, cool down to 75°C, and add 12.4g of trimethylolpropane and 110ml of acetone, add dropwise 63g of isophorone diisocyanate and 11.6g of 1,6-hexamethylene diisocyanate mixture, after the dropwise addition, react for 2.5 hours to obtain the first intermediate body.

[0075] Add 120ml of acetone to the first intermediate, lower the temperature to 70°C, add 0.0015g of dibutyltin dilaurate catalyst, and add 35g of dimethylolpropionic acid hydrophilic chain extender in three batches. After the addition is complete, the reaction is 0.5 hours, the second intermediate was obtained.

[0076] Add 180ml of acetone to the second intermediate, add 12.6g of diethylene glycol, raise the temperature to 85°C, and react for 2 hours. Cool down to 35°C, add 312g deionized water, then add 45g dimethylethanolamine, stir fo...

Embodiment 2

[0078] Add 700g of low molecular weight poly(carbonate-ether) glycol (molecular weight: 7000 Daltons) into the three-necked flask, heat to 120°C, dehydrate at -0.98MPa for 3 hours, cool down to 85°C, under nitrogen protection, add 14.5g of trimethylolpropane and 180ml of acetone, dropwise add 89g of isophorone diisocyanate and 23.8g of 1,6-hexamethylene diisocyanate mixture, after the dropwise addition, react for 4 hours to obtain the first intermediate body.

[0079] Add 270ml of acetone to the first intermediate, lower the temperature to 75°C, add 0.0045g of stannous octoate catalyst, add 78g of dimethylolpropionic acid hydrophilic chain extender in three batches, and react for 2 hours after adding, A second intermediate is obtained.

[0080] Add 260ml of acetone to the second intermediate, add 17g of diethylene glycol, raise the temperature to 90°C, and react for 3 hours. Cool down to 40°C, add 731g of deionized water, then add 62g of dimethylethanolamine, stir for 15min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

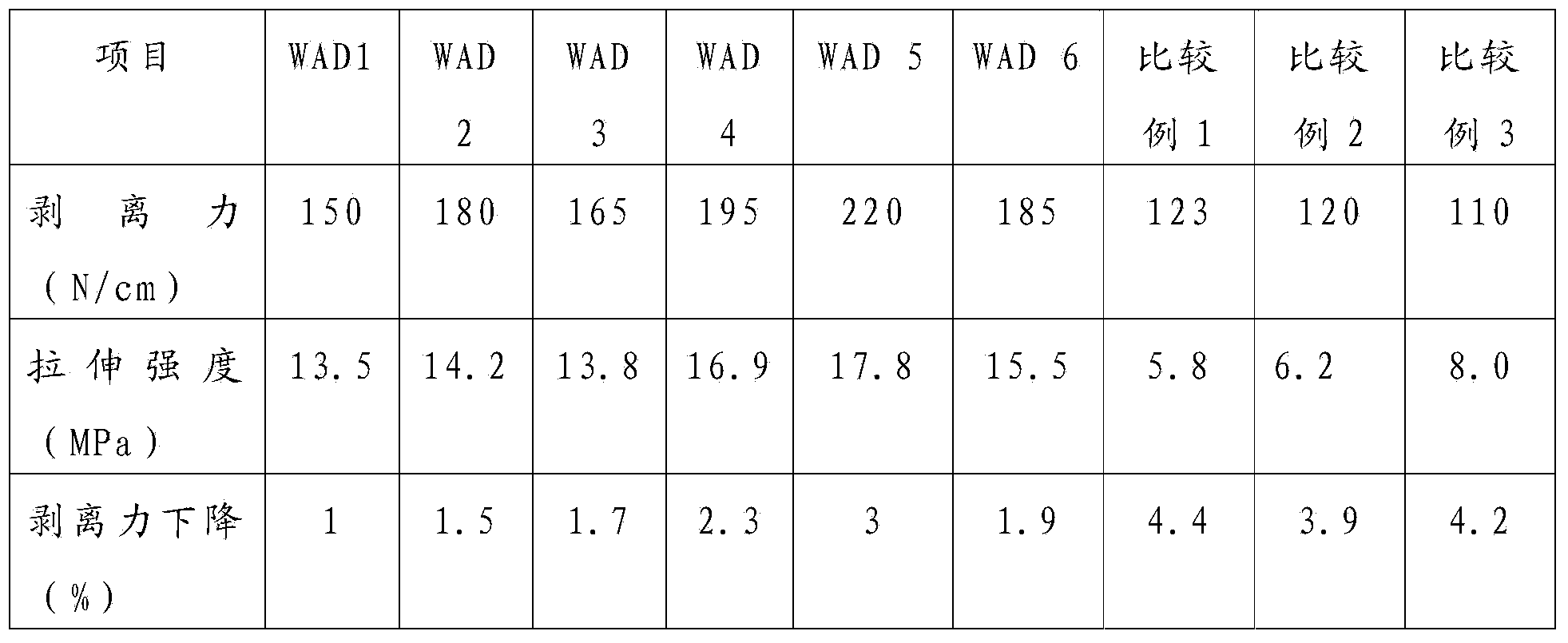

| Peel force | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com