Polyurethane shape memory macromolecule material and synthetic technique thereof

A technology of polymer material and synthesis process, applied in the field of preparation of temperature-controlled shape memory polymers, can solve the problems of unsatisfactory shape memory effect, unsatisfactory fabric color change practical value, unsatisfactory waterproof, breathable and moisture-permeable effects, etc. To achieve good waterproof effect, improve adaptability and comfort, and enhance the effect of moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

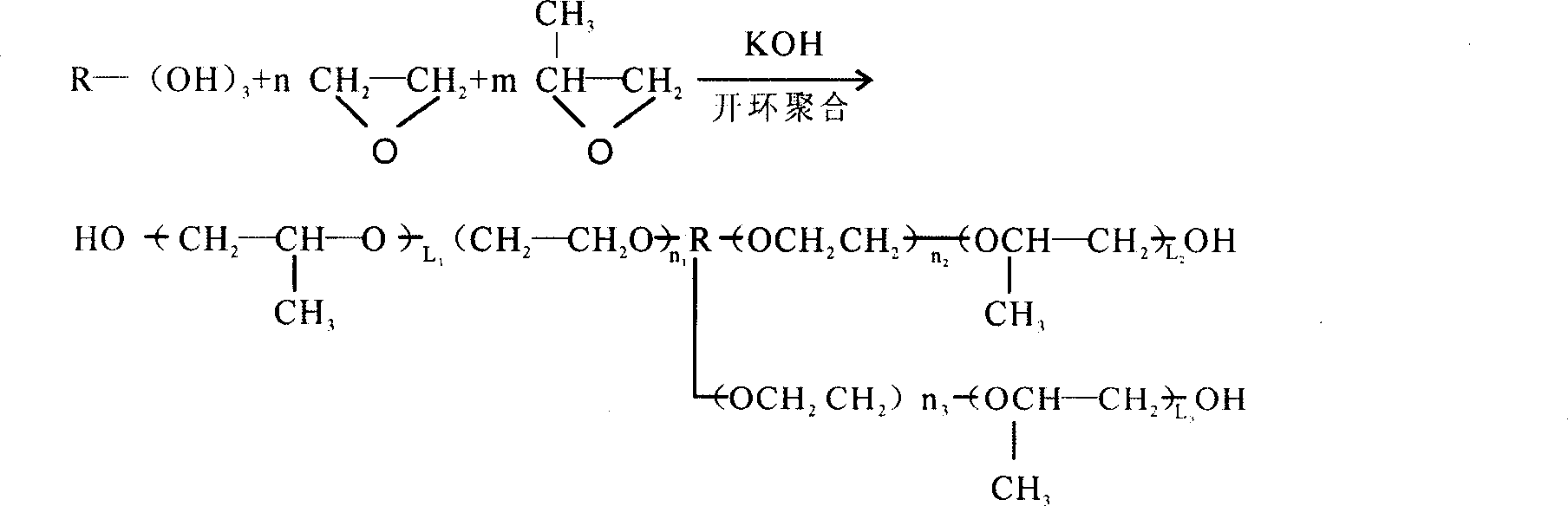

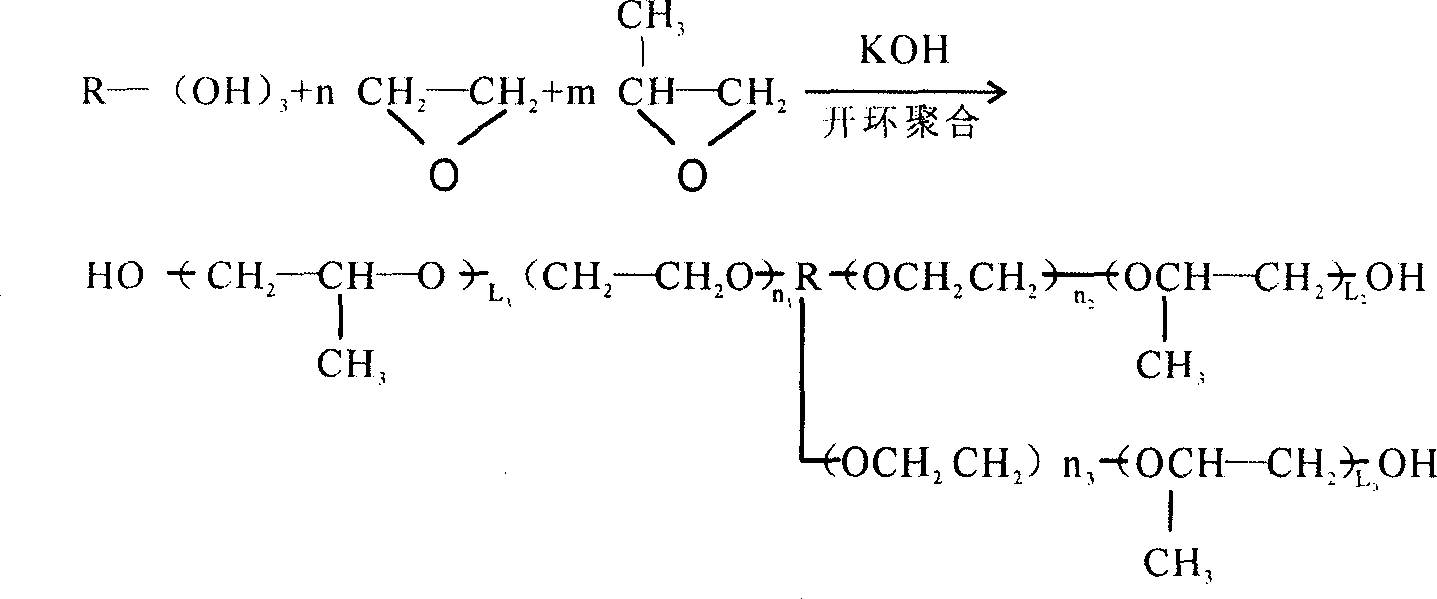

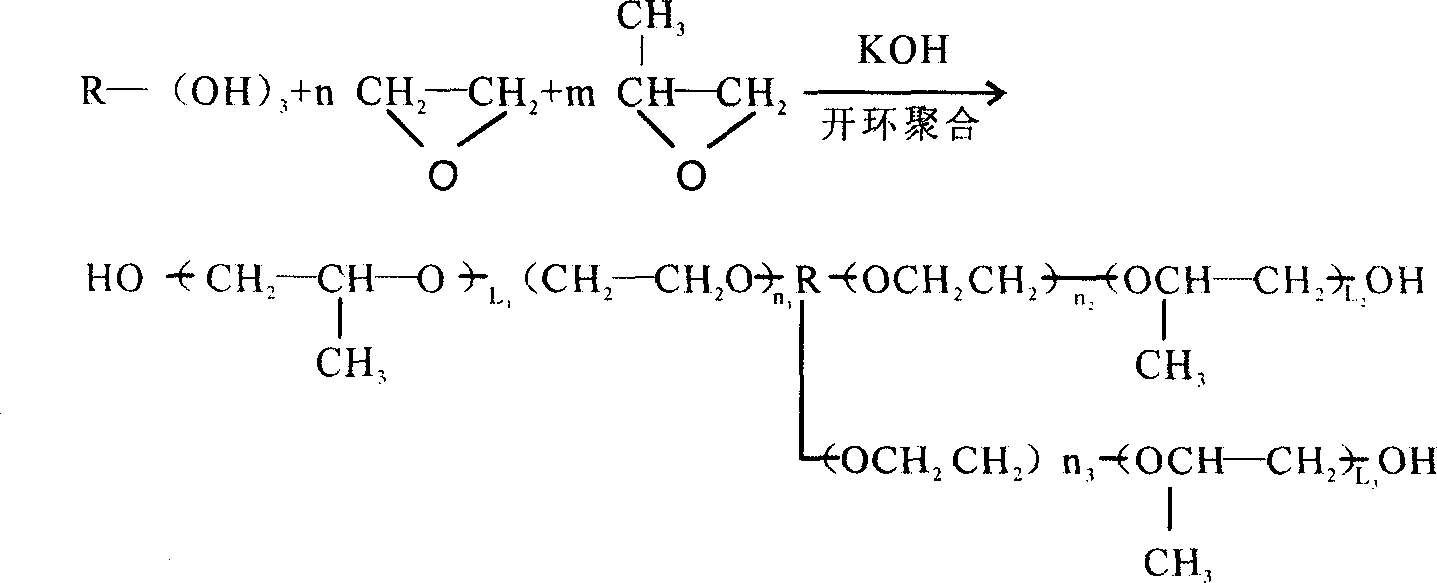

[0028] The raw material that needs to be self-made is polyether polyol, and the polyol initiator is glycerol and trimethylolpropane, the ratio is 1:1; the ratio of ethylene oxide and propylene oxide is 1:1. Hydroxyl value: 50-65, mgKOH / g functional group number: 3, acid value: 0.1-0.3mgKOH / g, moisture: 0.02-0.06%, appearance: light yellow, water solubility: soluble in water, pH value: 5-5.5 .

[0029] Polyether polyol synthesis reaction formula:

[0030]

[0031] The main technical indicators of the synthesized polyether polyol are shown in the table:

[0032] Table 1 Main technical indicators of polyether polyols

[0033] Hydroxyl value

Number of functional groups

Moisture (%)

Exterior

pH value

50-65

3

0.1-0.3

0.02-0.06

pale yellow

Dissolved in water

5-5.5

[0034] Note: The unit of hydroxyl value and acid value is mgKOH / g, and the pH value is 1% solution.

[003...

Embodiment 2

[0041] The polyol starter is glycerin and trimethylolpropane, the ratio is 1:4;

[0042] The ratio of ethylene oxide and propylene oxide is 1:5. The reaction is the same as above to prepare polyether polyol.

[0043] A polyurethane shape memory polymer material, completed by the following process,

[0044] (1) Vacuum dehydration of raw materials: N, N dimethylformamide and 1 4-butanediol are dried, and polyester polyol is vacuum dehydrated at 130°C for 3 hours;

[0045] (2) Prepolymerization reaction: N 2 Add 20 grams of 2,4-toluene diisocyanate and 20 ml of DMF under protected conditions, add 100 grams of measured polyester polyol dropwise, and stir and react at 65°C for 1.5 hours to obtain a prepolymer;

[0046] (3) Chain extension reaction: 5 grams of 1,4-BDO and 20 grams of dimethylolpropionic acid (DMPA) were added to the reactor for chain extension reaction for 3 hours to obtain the product after chain extension;

[0047] (4) Neutralization reaction: use 10-40 grams ...

Embodiment 3

[0049] The polyol starter is glycerin and trimethylolpropane, the ratio is 1:2;

[0050] The ratio of ethylene oxide and propylene oxide is 1:3. The reaction is the same as above to prepare polyether polyol.

[0051] A kind of synthetic technique of polyurethane shape memory polymer material, comprises following steps successively,

[0052] (1) Vacuum dehydration of raw materials: N, N dimethylformamide and 14-butanediol are dried, and polyether polyol is vacuum dehydrated at 120°C for 2 hours;

[0053] (2) Prepolymerization reaction: N 2 Add 30 grams of 2,4-toluene diisocyanate and 25 ml of DMF under protected conditions, add 120 grams of measured polyether polyol dropwise, and stir and react at 70°C for 2 hours to obtain a prepolymer;

[0054] (3) Chain extension reaction: 3 grams of 1,4-BDO and 35 grams of dimethylolpropionic acid (DMPA) were added to the reactor for chain extension reaction for 2 hours to obtain the product after chain extension;

[0055] (4) Neutraliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com