A kind of deformable airgel material and preparation method thereof

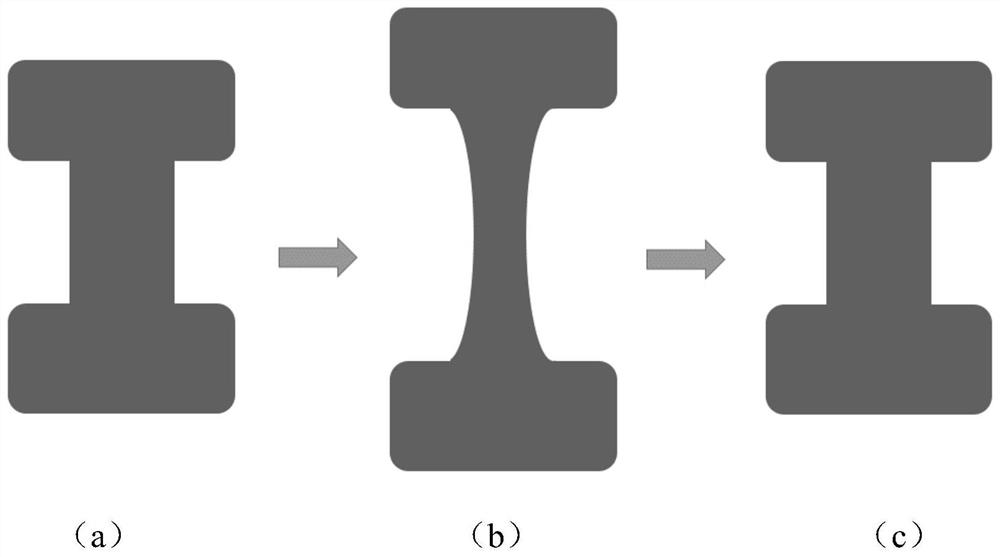

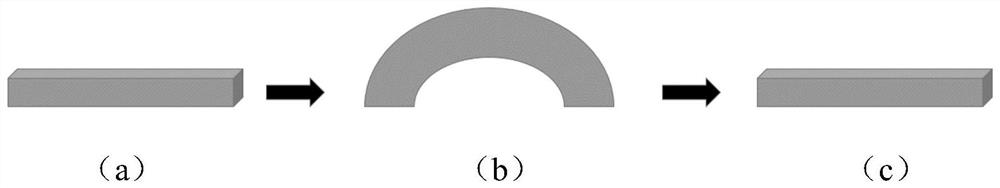

An aerogel and polyimide wet gel technology, which is applied in the field of deformable aerogel materials and their preparation, can solve the problems of low shape recovery rate and poor deformability, and achieves high shape recovery rate and porosity. The effect of high rate and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

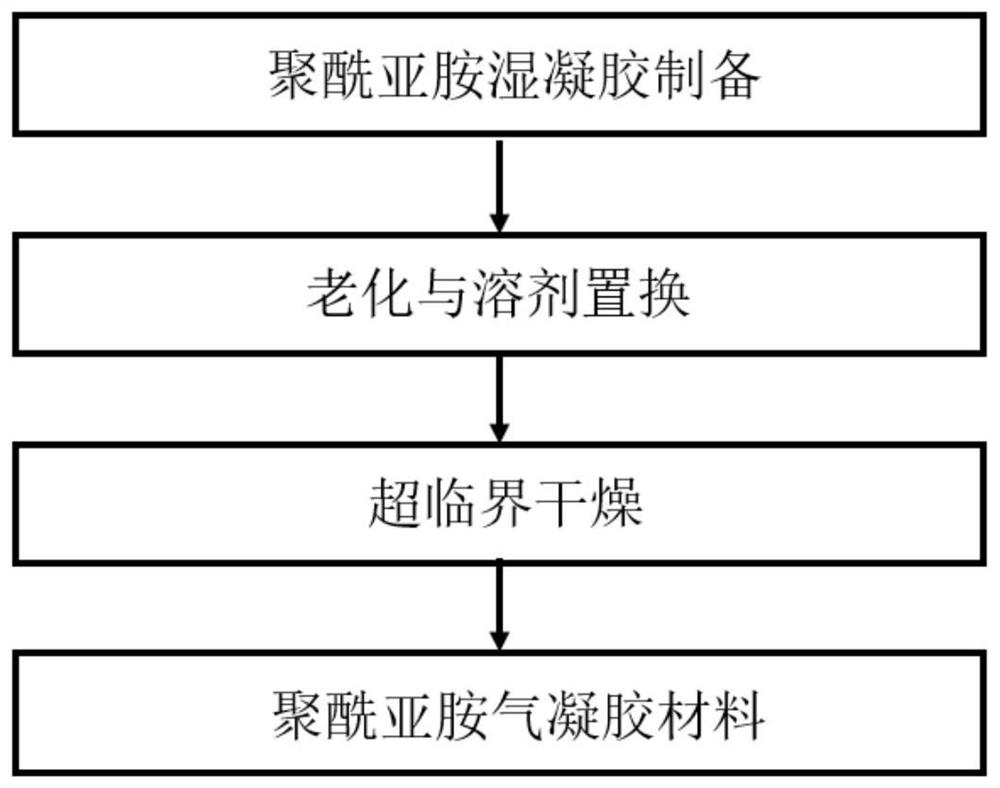

[0030] The present invention provides a kind of preparation method of deformable airgel material in the first aspect, it is characterized in that, described method comprises the following steps:

[0031] (1) Under the protection of an inert gas (such as nitrogen or argon), mix 2,2'-bis[4-(3-aminophenoxy)phenyl]hexafluoropropane (m-6FBAPP) and 4,4' -(hexafluoroisopropylene) diphthalic anhydride (6FDA) (non-coplanar crosslinking agent) is dissolved in a first organic solvent (such as N,N-dimethylacetamide (DMAc)) for polycondensation reaction to obtain a reaction solution ; Specifically, for example, under nitrogen protection, 2,2'-bis[4-(3-aminophenoxy)phenyl]hexafluoropropane (m-6FBAPP) was dissolved in N,N-dimethyl Acetamide (DMAc), stirring for 10 minutes; then adding 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6FDA) to the above solution, and stirring the whole system at room temperature for 5-48 hours to obtain the reaction solution.

[0032](2) Add 1,1,1-tris[4-...

Embodiment 1

[0060] ① Preparation of polyimide wet gel

[0061] Under nitrogen protection, 1.020g of 2,2'-bis[4-(3-aminophenoxy)phenyl]hexafluoropropane (m-6FBAPP) was dissolved in 10g of N,N-dimethylacetamide (DMAc) (the first organic solvent), stirring for 10 minutes; then adding 0.885g 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6FDA) to the above solution, and stirring the whole system at room temperature for 28 hours to obtain the reaction solution; add 0.0116g 1,1,1-tris[4-(aminophenoxy)phenyl]ethane (TAPE) and 5.4g N,N-dimethylacetamide (DMAc) to the reaction solution (second organic solvent), to obtain a uniform polyamic acid (PAA) solution, this time, adding 0.02g particle diameter to the PAA solution is the fumed silica nanoparticles of 30nm, stirred for 30min; The PAA solution was divided into two 50mL beakers, sealed with plastic wrap, and placed in a vacuum oven (the temperature of the vacuum oven was 40°C) for 1 hour, and then left to stand for 5 minutes to defoam; t...

Embodiment 2

[0068] Example 2 is basically the same as Example 1, except that the first organic solvent N,N-dimethylacetamide (DMAc) is used in an amount of 20g, and the second organic solvent N,N-dimethyl The amount of acetamide (DMAc) used is 10.8 g, and the total amount of the first organic solvent and the second organic solvent is 30.8 g.

[0069] Embodiments 3-9 are basically the same as Embodiment 1, and the differences are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com