A preparing method of water-based self-crosslinking acrylic acid modified polyurethane matte resin

A technology of self-crosslinking acrylic acid and matte resin, which is applied in the direction of coating, etc., can solve the problems of many side reactions of acrylic acid modification, unfavorable product stability, and over-complicated process, and achieve outstanding yellowing resistance and enhanced cross-linking density , good transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of preparation method of waterborne self-crosslinking acrylic acid modified polyurethane matte resin, its preparation process comprises the following steps:

[0022] 1) In the synthesis kettle, add 15 parts of polyethylene glycol monobutyl ether (Mr600) according to the formula, start vacuuming and heat to 120°C, dehydrate for 4 hours under vacuum (1.067kPa), and then fill N 2 , lower the temperature to 80°C and add 50 parts of IPDI trimer, 15 parts of NMP and 0.016 parts of DBTDL according to the formula, raise the temperature to 90-110°C and keep it warm for 2-3 hours, then cool down to 60°C, add 2.5 parts of 1 according to the formula For 4-butanediol, slowly raise the temperature to 80°C and react for 1 hour, then add 8 parts of DMPA and 5 parts of acetone, keep the temperature at 80-85°C for 4-5 hours; cool down to 60°C, add 10 parts of triethylamine to neutralize After reacting for 0.5h, stop feeding N 2, add 175 parts of deionized water under high-speed ...

Embodiment 2

[0026] A kind of preparation method of waterborne self-crosslinking acrylic acid modified polyurethane matte resin, its preparation process comprises the following steps:

[0027] 1) In the synthesis kettle, add 12.5 parts of polycarbonate diol (Mr1000) according to the formula, start vacuuming and heat to 120°C, dehydrate for 4 hours under vacuum (1.067kPa), and fill with N 2 , lower the temperature to 80°C and add 25.5 parts of HDI trimer, 10 parts of NMP and 0.015 parts of DBTDL according to the formula, raise the temperature to 90-110 °C and keep it warm for 2-3 hours, then cool down to 60 °C, add 1.2 parts of 1 according to the formula For 4-butanediol, slowly raise the temperature to 80°C and react for 1 hour, then add 4.8 parts of DMPA and 3 parts of acetone, keep the temperature at 80-85°C for 4-5 hours; cool down to 60°C, add 6 parts of triethylamine to neutralize After reacting for 0.5h, stop feeding N 2 , add 110 parts of deionized water under high-speed stirring, ...

Embodiment 3

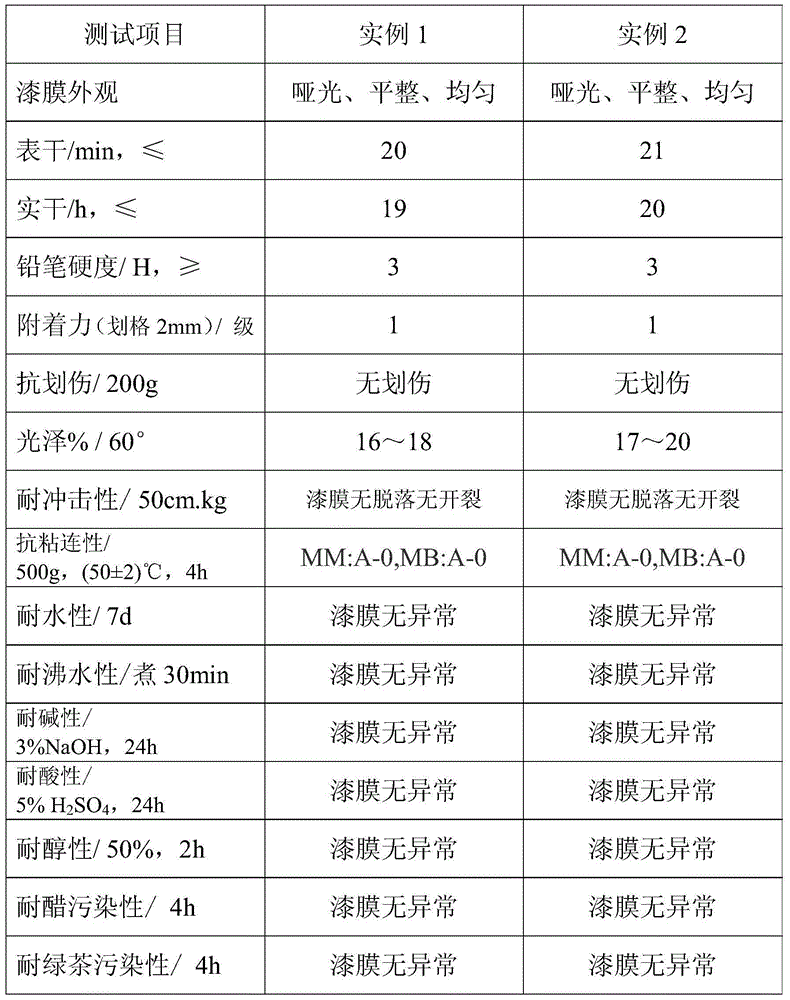

[0031] The water-based self-crosslinking acrylic acid-modified polyurethane matte resin in the above-mentioned examples 1 and 2 is used to prepare a one-component water-based woodware polyurethane matte varnish, and the formula is as follows: water-based self-crosslinking acrylic acid-modified polyurethane matte resin 75, primer Material wetting agent 0.2, leveling agent 0.2, defoamer 0.2, thickener 0.5, preservative 0.2, film-forming aid 3.0, PH regulator 0.1, water 21.0.

[0032] The basic properties of the above-mentioned one-component water-based polyurethane matt varnish for woodware were tested according to relevant national standards, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com