Preparation method and applications for metal monoatomic material

A metal atom and atom technology, which is applied in the field of preparation of metal single-atom materials, can solve the problems of inability to maintain metal-non-metal coordination active structure and structural instability, and achieve the advantages of simple preparation route, suppression of damage and improvement of material properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

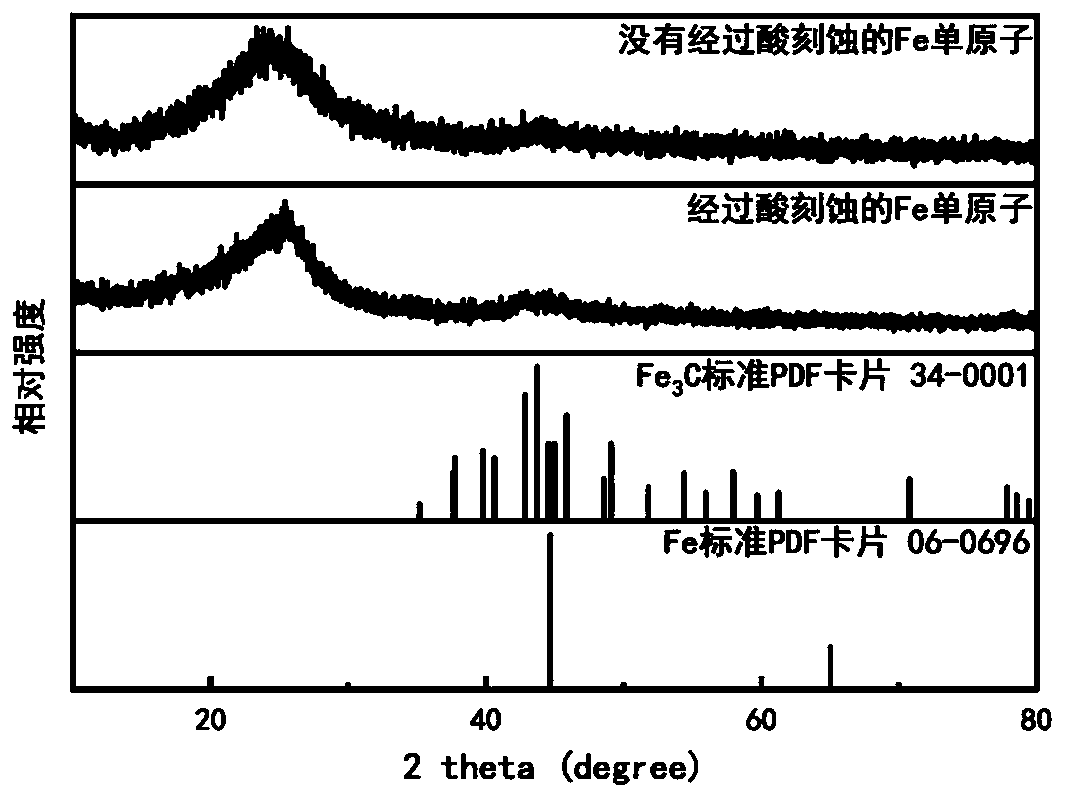

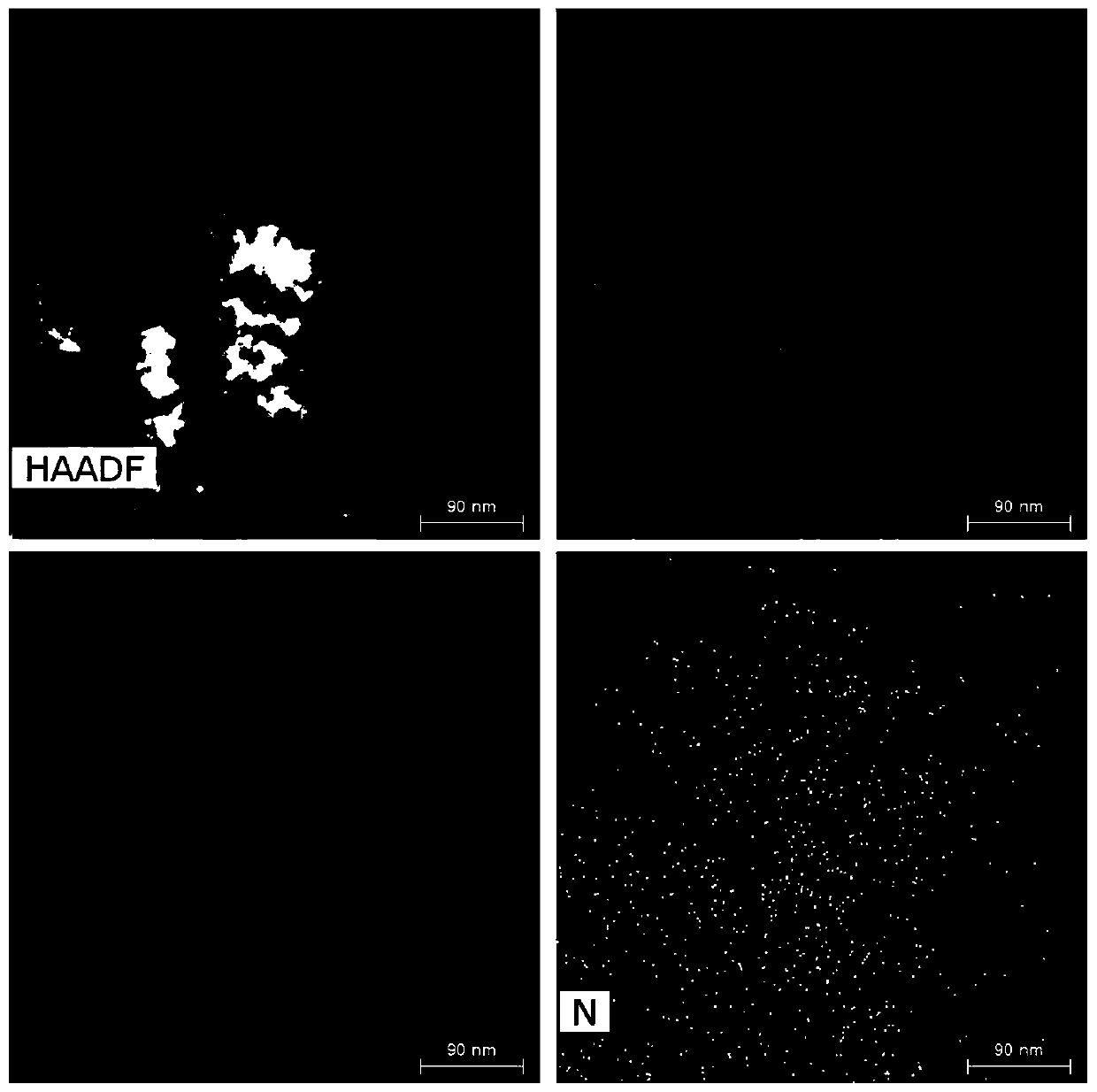

[0035] Preparation of Fe monoatomic materials: Weigh porphyrin iron and conductive carbon black with a mass ratio of 1:2, dissolve them in an appropriate volume of N,N-dimethylformamide (DMF), sonicate and stir for 24 hours to make them completely dispersed . Then put it into a blast drying box for solvent evaporation. Take the completely dried sample and place it in an agate mortar, add the protective agent tetraethyl silicate and the additive acetic acid in a volume ratio of 1:1, and then grind the solid-liquid mixture until it is completely dry. The powder was placed in a tube furnace, and the temperature was raised to 800°C in an argon atmosphere for high-temperature carbonization for 2h at a heating rate of 2°C / min. Then the temperature was naturally cooled to room temperature, and the black fluffy powder was obtained by taking out.

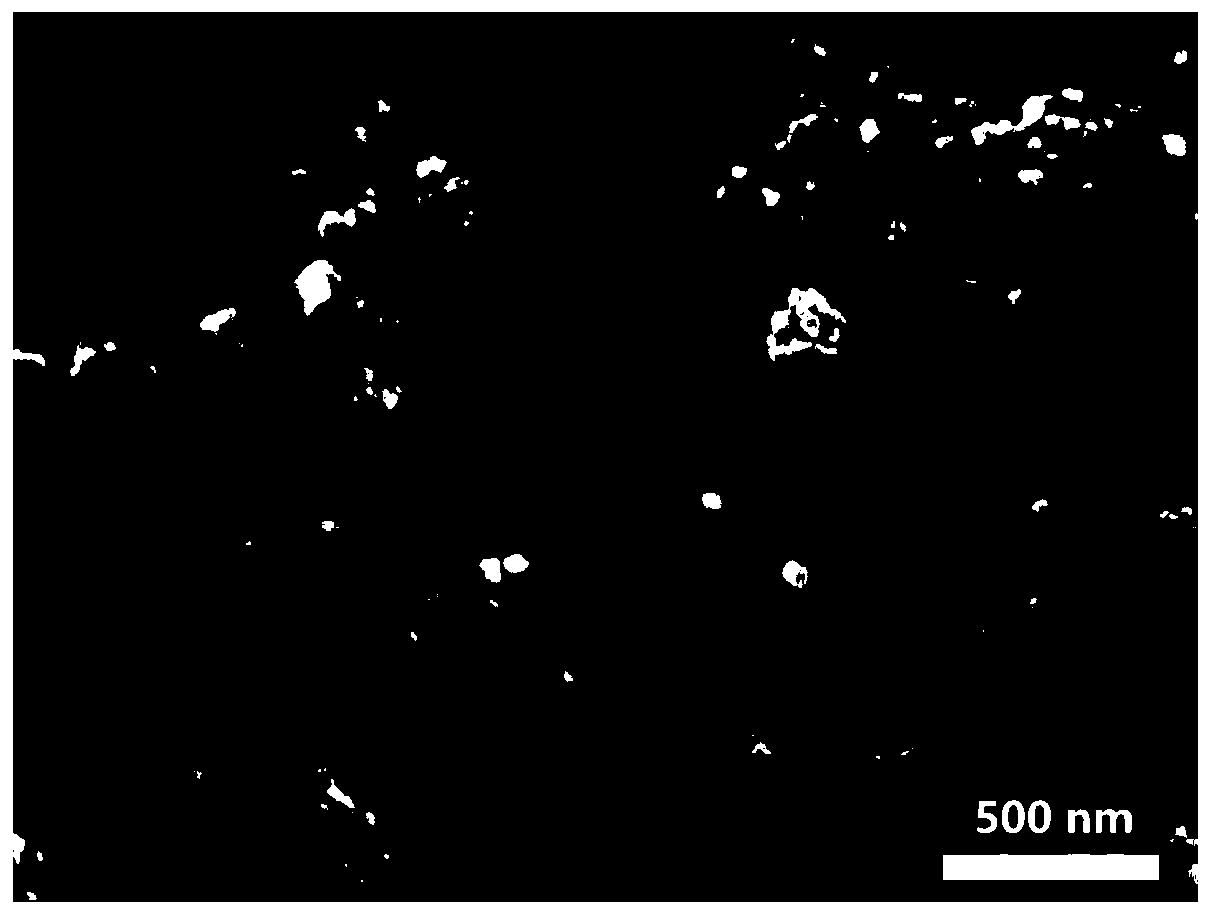

[0036] Add the black powder to an appropriate volume of a 1:1 mixed acid etching solution of hydrochloric acid and hydrofluoric acid for sti...

Embodiment 2

[0044] Preparation of Fe monoatomic material: Weigh porphyrin iron and glucose with a mass ratio of 1:5, dissolve them in an appropriate volume of N,N-dimethylformamide (DMF), sonicate and stir for 24 hours to completely disperse them. Then put it into a blast drying box for solvent evaporation. Take the completely dried sample and place it in an agate mortar, add the protective agent tetraethyl silicate and the additive hydrochloric acid in a volume ratio of 1:1, and then grind the solid-liquid mixture until it is completely dry. The powder was placed in a tube furnace, and the temperature was raised to 800°C in an argon atmosphere for high-temperature carbonization for 2h at a heating rate of 2°C / min. Then the temperature was naturally cooled to room temperature, and the black fluffy powder was obtained by taking out.

[0045] Add the black powder to an appropriate volume of a 1:1 mixed acid etching solution of nitric acid and hydrofluoric acid for stirring and etching for 12 ...

Embodiment 3

[0047] Preparation of Fe monoatomic material: Weigh iron phthalocyanine and carbon nanotubes with a mass ratio of 1:3, dissolve them in an appropriate volume of N,N-dimethylformamide (DMF), and stir for 24 hours to make them completely dispersed. . Then put it into a blast drying box for solvent evaporation. Take the completely dried sample and place it in an agate mortar, add the protective agent tetraethyl silicate and the additive nitric acid in a volume ratio of 1:1, and then grind the solid-liquid mixture until it is completely dry. The powder was placed in a tube furnace, and the temperature was raised to 800°C in an argon atmosphere for high-temperature carbonization for 2h at a heating rate of 2°C / min. Then the temperature was naturally cooled to room temperature, and the black fluffy powder was obtained by taking out.

[0048] Add the black powder to the appropriate volume of a 1:1 mixed acid etching solution of sulfuric acid and hydrofluoric acid for stirring and etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com