Patterned electrode preparation method

A patterned electrode and patterned technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of expensive, low-efficiency preparation methods, and no separation of graphics, and achieve easy promotion and use, effective preparation methods, and neat edges Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

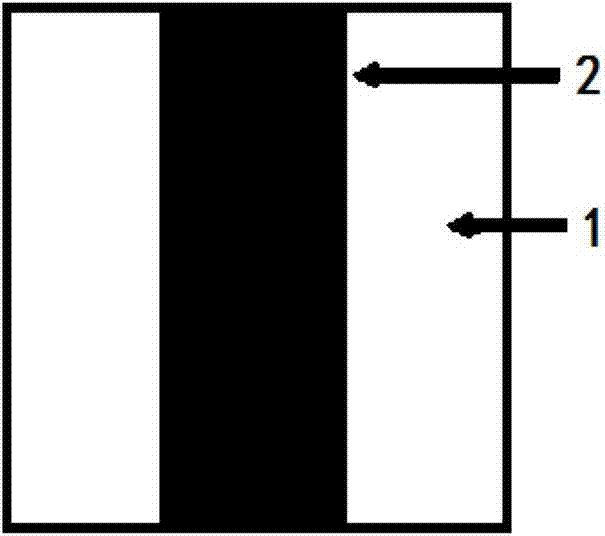

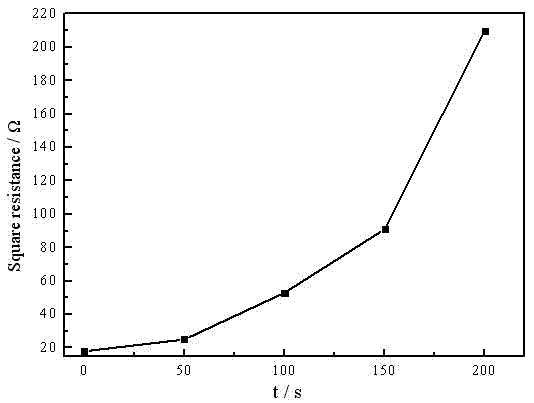

[0025] Use the UV inkjet printer to print the protective film corrosion method, respectively corrode the electrodes on the 25×25mm ITO conductive substrate, the size is 10×25mm, such as figure 1 As shown, the black area is the ITO electrode. The corrosion time was 50 s, 100 s, 150 s, and 200 s, and the corrosion solution was prepared by mixing 36% hydrochloric acid, 98% nitric acid, and deionized water at a volume ratio of 10:0.8:10. Formed, using the sheet resistance tester to measure the sheet resistance of the electrode under different corrosion times, such as figure 2 As shown, the change trend of the sheet resistance with time, and a patterned ITO electrode can be obtained between 50 s and 200 s, and the edges of the graph are neat, such as image 3 As shown, the figure is a 500-fold micrograph. It can be seen from the figure that at the corroded interface of the ITO electrode, the edge is still very clear when magnified by a microscope 500 times, without jaggedness...

Embodiment 2

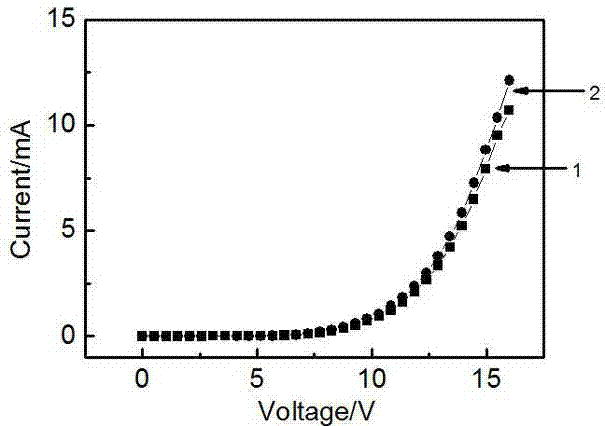

[0027] Substrates (25×25mm) with ITO conductive electrodes (10×25mm) were prepared by photoresist mask and UV inkjet printer printing protective film corrosion method, and the structure was prepared on this basis: glass / ITO (180nm) / NPB(50nm) / DCM: (Alq3 0.5% 20nm) / Alq3(30nm) / Ca(10nm) / Ag OLED device, in which ITO is the anode, NPB is the hole transport layer, DCM is the light emitting layer, Alq3 is the electron transport layer, Ca is the buffer layer, and Ag is the cathode. Among them, the ITO electrodes of group A devices are prepared by photolithography etching, and the ITO electrodes of group B devices are prepared by UV inkjet printer printing protective film corrosion method. The specific process is as follows:

[0028] (1) The substrates of group A and B devices are glass with ITO electrodes. Firstly, the substrates are scrubbed and cleaned. The size is 10×25mm;

[0029] (2) Place the processed device substrates of groups A and B in a multi-source organic molecular vapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com