High-transparency copolymerization type fluorine-containing polyimide thin material and preparation method of high-transparency copolymerization type fluorine-containing polyimide thin material

The technology of polyimide film and polyimide resin is applied in the field of highly transparent copolymerized fluorine-containing polyimide film material and its preparation, which can solve the problems of dark color and poor optical transparency, and achieve high optical transparency. excellent heat resistance, simple preparation route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

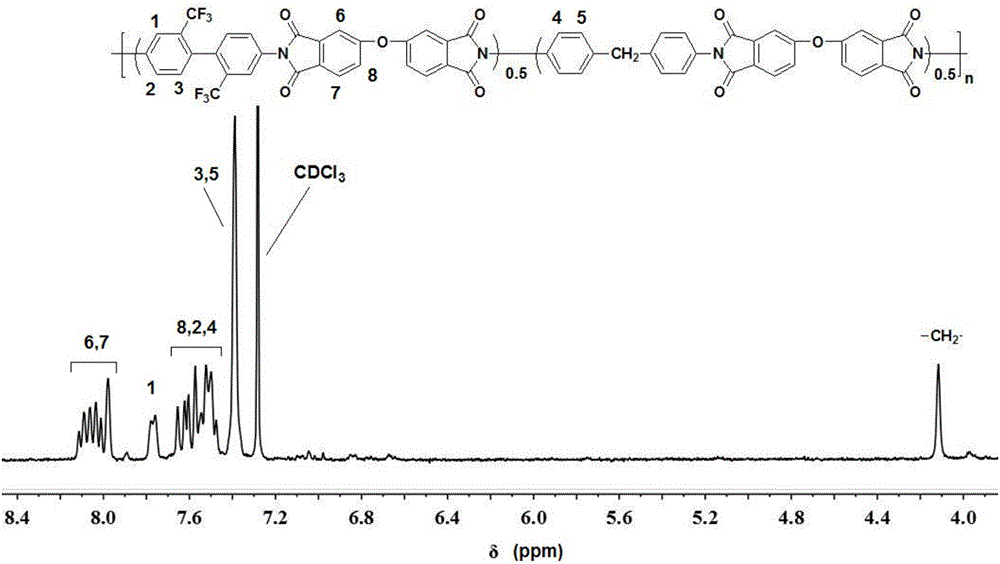

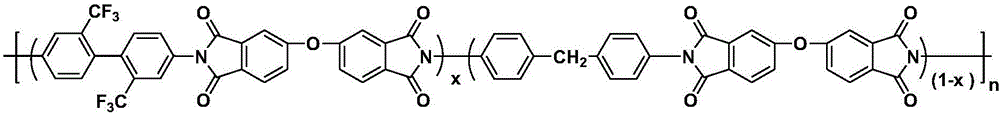

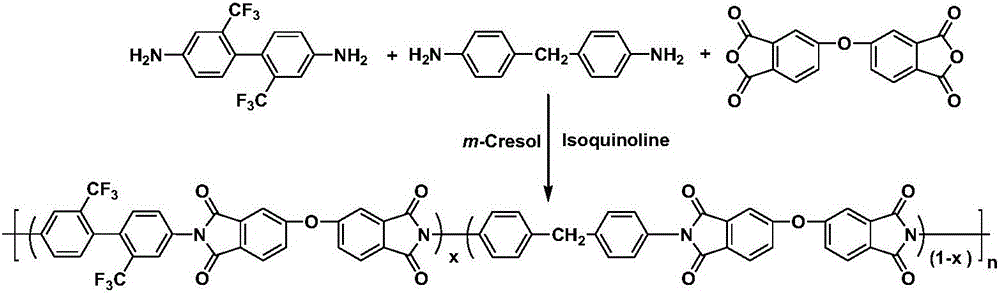

[0021] (1) Add 0.9606g (3mmol) of 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl and 0.5948g (3mmol) of a three-neck dry round-bottomed flask with nitrogen gas. 4,4'-diaminodiphenylmethane and 1.861g (6mmol) of diphenyl ether tetra-acid dianhydride three monomers, then add 17.1g m-cresol as solvent, stir and dissolve at room temperature, add 0.35g iso Quinoline was used as a catalyst, the temperature was raised to 170°C, and the reaction solution was poured into 500ml of ethanol, filtered, and dried to obtain a fibrous copolymerized fluorine-containing polyimide resin through a nitrogen flow with water and stirred for 12 hours. 98%.

[0022] (2) Further dissolve the polyimide resin in the chloroform solution to make a 5wt% polymer solution, coat the polymer solution on the flat glass, and dry it in an oven at 30° C. for 24 hours to obtain high transparency Copolymerized fluorine-containing polyimide film samples.

Embodiment 2

[0024] (1) Add 1.2809g (4mmol) of 2,2'-bistrifluoromethyl-4,4'-diaminobenzidine, 0.3965g (2mmol) respectively to a 50ml dry round-bottomed three-necked flask with nitrogen gas. 4,4'-diaminodiphenylmethane and 1.861g (6mmol) of diphenyl ether tetra-acid dianhydride three monomers, then add 35.3g of m-cresol as a solvent, stir the reaction at room temperature to dissolve, add 1.4g Isoquinoline is used as a catalyst, the temperature is raised to 190°C, and the reaction solution is poured into 1000ml of ethanol, filtered, and dried to obtain a fibrous copolymerized fluorine-containing polyimide resin. The rate is 98%.

[0025] (2) Further dissolve the polyimide resin in N,N-dimethylacetamide solution to form a 10wt% polymer solution, coat the polymer solution on flat glass, and place it in an oven at 70°C After drying for 24 hours, a highly transparent polyimide film sample can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com